Get in touch with us

Leave a message

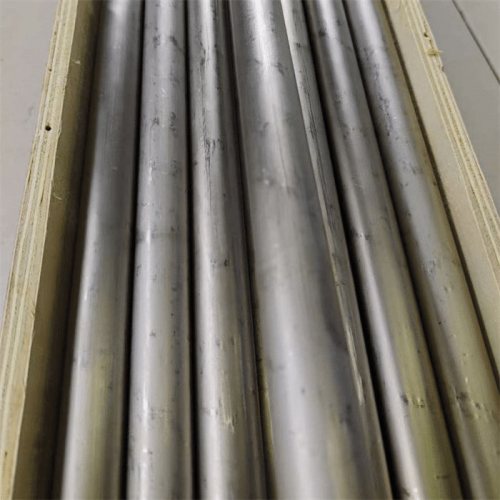

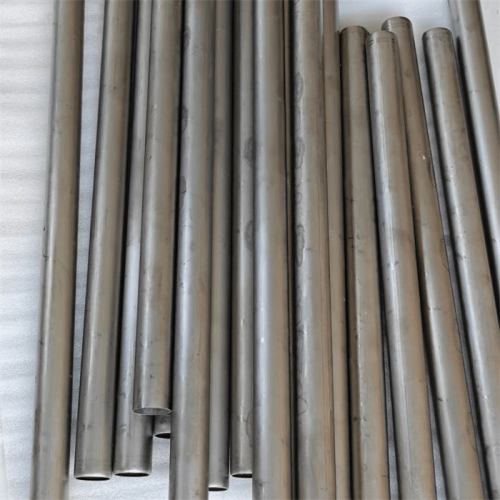

From 316 steel tubing in refineries to 316 corrugated stainless steel tubing in HVAC, its applications are extensive.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 16.0–18.0 |

| Nickel (Ni) | 10.0–14.0 |

| Molybdenum (Mo) | 2.0–3.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 515–690 MPa |

| Yield Strength (0.2%) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (Brinell) | ≤ 217 HB |

| Density | 8.0 g/cm³ |

The 316 Stainless Steel Tube resists:

Our China distributor can suggest alternatives if needed.

| Environment | Corrosion Resistance | Notes |

|---|---|---|

| Atmospheric (Urban/Coastal) | Excellent | Resists rust in humid and salty conditions. |

| Saltwater (Marine) | Excellent | Superior resistance to pitting and chlorides. |

| Mild Acids (e.g., Sulfuric) | Good | Handles dilute acids well; test for strong acids. |

| Alkaline Solutions | Excellent | Strong resistance to bases like sodium hydroxide. |

| Industrial Chemicals | Good to Excellent | Effective against mild solvents; depends on concentration. |

Contact us for detailed corrosion resistance data specific to your application.

Welding 316 Stainless Steel Pipe is efficient:

Tips:

Our 316 Pipe Cutting services simplify fabrication.

Mark S.

Shipbuilder

Lisa T.

Engineer

Tom R.

Mechanic

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.