Get in touch with us

Leave a message

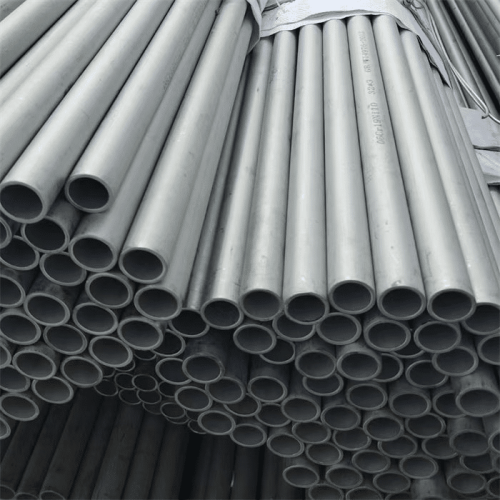

Our 321 Stainless Steel Tube is available in various forms:

The 321 Stainless Steel Tube serves diverse industries:

Its uses are extensive from 321 steel tubing in refineries to 321 corrugated stainless steel tubing in HVAC.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Chromium (Cr) | 17.0–19.0 |

| Nickel (Ni) | 9.0–12.0 |

| Titanium (Ti) | ≤ 0.70 (5xC min) |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 515–690 MPa |

| Yield Strength (0.2%) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (Brinell) | ≤ 217 HB |

| Density | 8.0 g/cm³ |

The 321 Stainless Steel Tube resists:

Our China distributor can recommend alternatives if needed.

| Environment | Corrosion Resistance | Notes |

|---|---|---|

| Atmospheric (Urban/Rural) | Excellent | Resists rust in typical outdoor conditions. |

| High Temperature (Oxidizing) | Excellent | Stable up to 900°C in oxidizing environments. |

| Mild Chemicals | Good | Handles dilute acids and cleaners effectively. |

| Saltwater (Coastal) | Moderate | Susceptible to pitting with prolonged exposure. |

| Industrial Atmospheres | Good | Resists mild pollutants; monitor heavy exposure. |

Contact us for detailed corrosion resistance data specific to your application.

Welding 321 Stainless Steel Pipe is efficient:

Tips:

Our 321 Pipe Cutting services streamline fabrication.

Alex R.

Aerospace Technician

Emily K.

Process Engineer

Tom L.

Mechanic

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.