Get in touch with us

Leave a message

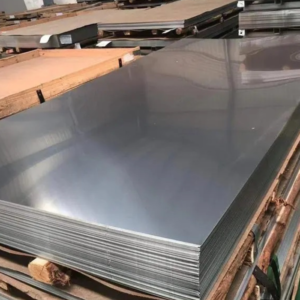

Discover our premium selection of stainless steel sheets, available in various grades including the popular 304 stainless steel. We offer both cold rolled and hot rolled options with finishes like 2B for diverse applications. Whether you need thin SS sheets for precision work or thick stainless steel plates for heavy-duty projects, our inventory includes standard dimensions and custom sizes. Our perforated stainless steel sheets provide excellent aesthetic and functional solutions at competitive prices. Trust our quality metal sheets for superior corrosion resistance and durability in industrial, architectural, and commercial applications.

Stainless Steel Sheet and Stainless Steel Plate are governed by standards like ASTM A240, A480, and A666, ensuring quality across grades such as 304, 316, 430, and 410. These standards define properties like corrosion resistance, thickness, and finish. For instance, a 304 Stainless Steel Sheet aligns with ASTM A240 for general use, while 316 offers superior pitting resistance per the same spec. Classifications split into austenitic (e.g., 304, 316), ferritic (e.g., 430), and martensitic (e.g., 410) types, with grades further distinguished by finishes like 2B finish stainless steel or brushed options. Stainless Steel Plate, typically thicker than 0.1875″ (4.76mm), adheres to similar standards but is often tailored for structural applications.

Stainless Steel Sheet comes in a wide range of sizes to suit diverse needs. Common dimensions include:

This flexibility ensures Stainless Steel Sheet and Stainless Steel Plate fit everything from small fabrications to large industrial builds.

Stainless Steel Sheet and Stainless Steel Plate come in various forms and finishes, each tied to specific manufacturing processes:

| Grade | Characteristics | Applications |

|---|---|---|

| 304 | Excellent corrosion resistance. Good formability and weldability. Non-magnetic. Moderate strength. | Food processing (e.g., countertops, tanks). Architectural trim. Automotive parts (e.g., exhausts). Kitchenware (e.g., sinks). |

| 304L | Enhanced weldability. Similar corrosion resistance to 304. Reduced risk of weld decay. | Welded structures (e.g., pipes, vessels). Chemical processing equipment. Food industry applications. |

| 316 | Superior corrosion resistance (especially in chloride environments). High durability. | Marine components (e.g., boat fittings). Chemical processing plants. Surgical instruments. Coastal architecture. |

| 316L | Excellent pitting resistance. Easier to weld than 316. High strength at elevated temperatures. | Pharmaceutical equipment. Marine hardware. Heat exchangers. Welded pressure vessels. |

| 430 | Magnetic. Good corrosion resistance. Lower cost than 300 series. Limited weldability. | Automotive trim. Appliance interiors (e.g., refrigerators). Decorative panels. Exhaust systems. |

| 410 | High strength and hardness (when heat-treated). Moderate corrosion resistance. Magnetic. | Cutlery. Turbine blades. Valves and pump parts. Fasteners. |

| 2205 (Duplex) | High strength. Excellent resistance to stress corrosion cracking. | Oil and gas piping. Structural components (e.g., bridges). Chemical tanks. Pulp and paper industry. |

A:A stainless steel sheet is a flat, thin piece of stainless steel, typically under 6mm thick, available in grades like 304 or 316. It’s used in construction, kitchen appliances, and automotive parts for its durability.

A:A 2mm stainless steel sheet (e.g., 304) has a tensile strength of 500-700 MPa, depending on the grade. It can withstand moderate loads but may flex under heavy pressure, suitable for cladding or light structural use.

A:Bend stainless steel sheets using a press brake at room temperature for thinner sheets (e.g., 2mm). For thicker sheets, heat to 800-1000°C to reduce work-hardening, ensuring a smooth bend without cracking.

A:Stainless steel sheets can be joined by welding (TIG/MIG), riveting, or using adhesives. TIG welding with proper shielding gas ensures strong, corrosion-resistant joints for grades like 316.

A:Magnets stick to ferritic stainless steel sheets (e.g., 430), but not to austenitic grades like 304 or 316, which are non-magnetic in the annealed state, unless cold-worked.

A:Stainless steel sheets resist rust due to their chromium content, but 304 may rust in saltwater. 316 sheets, with molybdenum, are more resistant, especially in marine or chloride-rich environments.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.