Get in touch with us

Leave a message

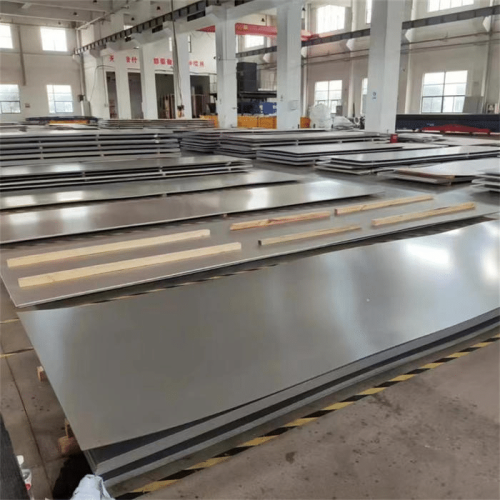

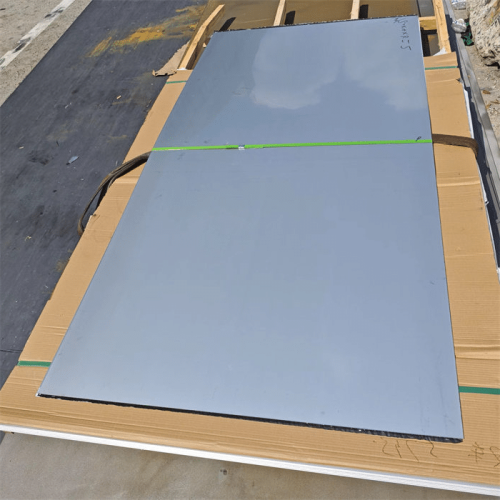

The 316L Stainless Steel Plate is a top choice for industrial applications when durability meets versatility. Known for its exceptional corrosion resistance and weldability, this low-carbon alloy is a favorite across marine, chemical processing, and food production industries. Sourced from leading manufacturers in China, our 316L stainless steel sheet and plate offerings deliver strength and reliability where it matters most. This product promises lasting performance after a 316L 2B stainless steel finish or a 316L perforated sheet.

Our 316L stainless steel sheet and plates meet rigorous industry standards. Here’s what you can expect:

The 316L stainless steel plate is a go-to material across multiple industries:

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 16.0–18.0 |

| Nickel (Ni) | 10.0–14.0 |

| Molybdenum (Mo) | 2.0–3.0 |

| Carbon (C) | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 0.75 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 515 MPa (75 ksi) |

| Yield Strength (0.2%) | ≥ 205 MPa (30 ksi) |

| Elongation (%) | ≥ 40% |

| Hardness (Rockwell B) | 79–95 |

The 316L plate excels in resisting:

While 316L stainless steel sheet is exceptional, consider these constraints:

| Environment | Resistance Level |

|---|---|

| Atmospheric (Rural) | Excellent |

| Atmospheric (Marine) | Very Good |

| Potable Water (1000 mg/L Cl⁻) | Good (up to 60°C) |

| Mild Chemicals | Excellent |

| Warm Chloride Solutions | Susceptible to pitting |

Contact us for detailed corrosion resistance data specific to your application.

John M.

Marine Engineer

Sara L.

Pharma Supplier

Mike T.

Architect

A: The molybdenum in 316L ss sheet boosts corrosion resistance, especially in salty or acidic conditions, unlike 304.

A: No, it’s non-magnetic in its annealed state, though cold working may induce slight magnetism.

A: It depends on size and finish—contact us for an exact price quote!

A: Yes, it’s ideal for marine use, though avoid prolonged exposure to warm seawater to prevent pitting.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.