Get in touch with us

Leave a message

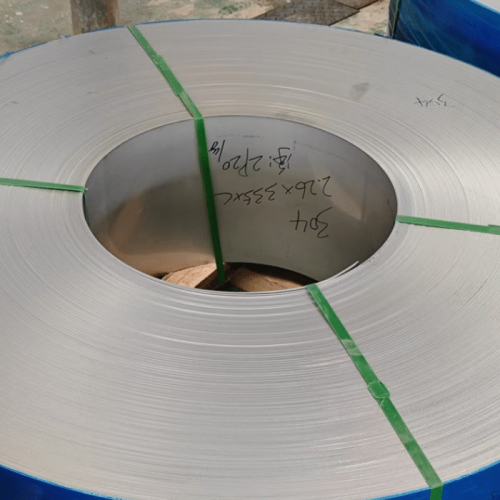

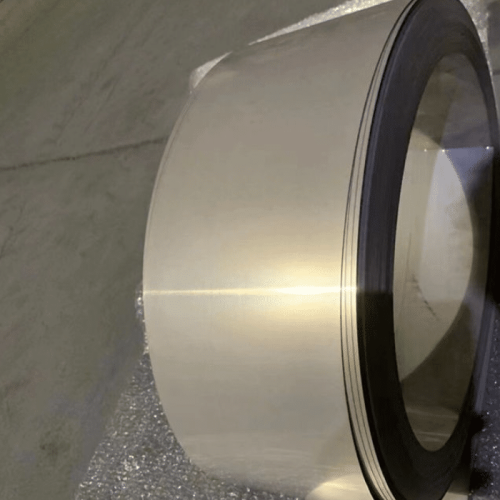

The 304 stainless steel strip is a versatile, austenitic stainless steel known for its exceptional corrosion resistance, strength, and formability, making it a top choice for various applications. Produced by leading manufacturers in China, it’s widely used in food processing, chemical equipment, architectural projects, and more, thanks to its resistance to oxidation and acids. Whether you need a 304 stainless steel strip roll or 304 cold-rolled steel strip, this product offers unmatched reliability and performance for industrial and decorative needs.

Are you looking to buy a 304 stainless steel strip? Contact our China manufacturer for a tailored quote. Pricing for 304 ss strips, including options like 304 ss strip roll, 304 stainless strips, and 304 cold-rolled steel strip, varies based on thickness, width, and surface finish—contact sales for competitive pricing and bulk order terms on 304 stainless steel metal strips.

Here’s a detailed breakdown of the technical specs for 304 ss strip:

These specifications ensure precision for applications requiring 304 ss strips or strips in various widths and finishes.

The 304 ss strip is highly versatile, serving multiple industries and uses:

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 18.0–20.0 |

| Nickel (Ni) | 8.0–10.5 |

| Carbon (C) | ≤0.08 |

| Silicon (Si) | ≤0.75 |

| Manganese (Mn) | ≤2.0 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.030 |

| Nitrogen (N) | ≤0.10 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 515–620 MPa |

| Yield Strength | 205–310 MPa |

| Elongation | 40–60% |

| Hardness (Brinell) | ≤201 HBW |

| Hardness (Rockwell B) | ≤92 HRB |

| Modulus of Elasticity | 193 GPa |

The 304 ss strip offers superior resistance to:

While versatile, 304 ss strip has some constraints:

| Environment | Corrosion Rate |

|---|---|

| Atmospheric Corrosion (Rural) | <0.001 mm/year |

| Atmospheric Corrosion (Urban) | <0.001 mm/year |

| Atmospheric Corrosion (Marine) | 0.001–0.005 mm/year |

| Fresh Water | <0.001 mm/year |

| Salt Water | 0.005–0.015 mm/year |

| Mild Organic Acids | <0.001 mm/year |

| Strong Acids | 0.01–0.1 mm/year |

| Alkaline Solutions | <0.001 mm/year |

| Chlorinated Water | 0.002–0.01 mm/year |

| Intergranular Corrosion | Negligible |

Contact us for detailed corrosion resistance data specific to your application.

The 304 ss strip from this China manufacturer is perfect for our equipment. Its corrosion resistance is top-notch—highly recommend!

Sarah T.

Food Processing Engineer

We used the 304 stainless strips for decorative panels, and the finish is stunning. The durability and price are excellent for our projects.

Mike L.

Architect

Our 304 ss strip roll arrived on time, and it’s been reliable for trim components. The factory’s quality control is impressive.

John R.

Automotive Supplier

A: 304 ss strip is more affordable but has less corrosion resistance than 316, especially in chloride-rich environments. It’s ideal for 304 stainless steel strip in general industrial uses, while 316 suits marine or harsh chemical settings.

A: It’s perfect for food processing, chemical equipment, and architectural projects. Avoid extreme chloride or high-temperature environments for ss 304 strip without proper treatment to prevent corrosion.

A: Pricing varies by thickness, finish, and volume. Contact our China manufacturer at sales for a quote on 304 ss strip price or 304 ss strip roll options.

A: Yes, but it’s best for mild outdoor conditions. In coastal or chloride-rich areas, use protective coatings or maintenance to prevent corrosion of 304 ss strips.

A: Yes, 304 cold-rolled steel strip welds well with TIG or MIG using 308L/309L fillers, ensuring strong, corrosion-resistant joints for 304 stainless steel strip applications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.