Get in touch with us

Leave a message

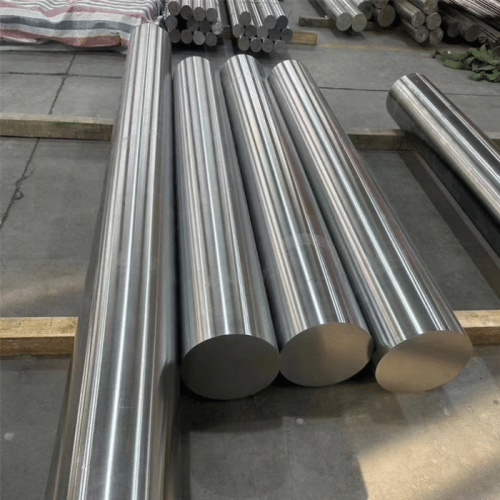

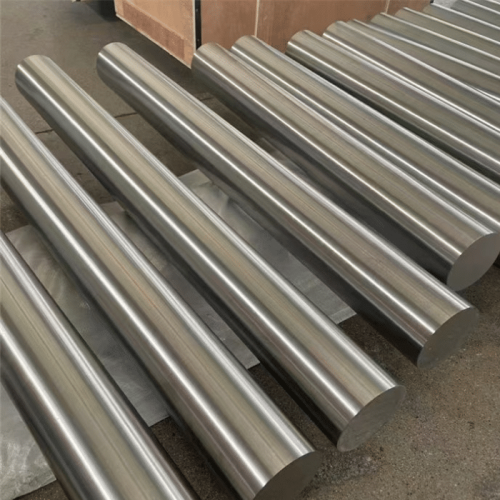

The Grade 1 Titanium Bar, also referred to as a Grade 1 titanium rod, is a commercially pure titanium product known for its excellent corrosion resistance, high ductility, and formability. As the softest and most ductile grade of titanium, it is ideal for applications where corrosion resistance and workability are prioritized over strength. As a premier Grade 1 Titanium Bar manufacturer in China, we offer high-quality bars for industries requiring reliable and pure titanium solutions.

For the most competitive pricing on Grade 1 Titanium Bar, reach out to our sales team directly. We offer customized quotes for Grade 1 Titanium Bar price based on your specific requirements, including dimensions, quantity, and delivery timelines. Contact us today to discuss your needs!

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | 99.5 min |

| Iron (Fe) | 0.2 max |

| Oxygen (O) | 0.18 max |

| Carbon (C) | 0.08 max |

| Nitrogen (N) | 0.03 max |

| Hydrogen (H) | 0.015 max |

| Property | Value |

|---|---|

| Tensile Strength | 240 MPa (min) |

| Yield Strength (0.2% offset) | 170 MPa (min) |

| Elongation | 24% (min) |

| Hardness (Brinell) | 120 HB (typical) |

| Density | 4.51 g/cm³ |

Grade 1 Titanium Bar exhibits exceptional resistance to various corrosive environments:

| Environment | Corrosion Rate (mm/year) | Conditions | Notes |

|---|---|---|---|

| Stagnant Seawater | <0.001 | 25°C, 12 months exposure | No pitting observed |

| 5% Sulfuric Acid | 0.01 | 30°C, 3 months exposure | Good resistance in dilute solutions |

| 5% Hydrochloric Acid | 0.03 | 25°C, 1 month exposure | Moderate resistance |

| Atmospheric (Coastal, Humid) | <0.001 | 25°C, 12 months exposure | Excellent resistance |

| 5% Sodium Hydroxide (Alkaline) | <0.002 | 40°C, 3 months exposure | Excellent resistance |

| 5% Nitric Acid | <0.001 | 30°C, 3 months exposure | Superior resistance |

We’ve been using Grade 1 Titanium Bar for our coastal building cladding projects, and the corrosion resistance in humid, salty air is incredible. This China-based manufacturer delivered perfectly polished Grade 1 titanium round bar that met our aesthetic and durability needs. Their attention to detail was impressive!

Peter H.

Architectural Designer

The Grade 1 Titanium Bar we sourced for our pacemaker components has been a perfect fit. Its biocompatibility and ease of machining made it ideal for our precision medical devices. The supplier provided high-quality Grade 1 titanium rod with consistent properties. A fantastic collaboration!

Dr. Clara M.

Biomedical Researcher

We ordered Grade 1 Titanium Bar for our heat exchanger components, and the performance in corrosive chemical environments has been outstanding. The ductility of their Grade 1 titanium industrial bar allowed us to fabricate complex shapes easily. This manufacturer is now our go-to for titanium solutions!

Tom W.

Chemical Equipment Supplier

A: Grade 1 Titanium Alloy Rod has lower oxygen content, offering higher ductility and better formability than Grade 2, while maintaining similar corrosion resistance. It’s ideal for applications requiring extensive shaping over Grade 2’s slightly higher strength.

A: Yes, Grade 1 Titanium Bar retains its ductility and toughness at cryogenic temperatures, making it suitable for applications like cryogenic storage tanks or low-temperature piping systems.

A: Titanium Rod offers superior resistance to dilute acids and seawater compared to most stainless steels, which may pit or corrode in similar conditions, making it a better choice for chemical and marine applications.

A: Absolutely, we offer tailored solutions such as custom diameters, lengths, and finishes for Grade 1 Titanium Alloy Rod to meet your exact specifications. Contact us to discuss your requirements.

A: Our Grade 1 Titanium Bar complies with standards like ASTM B348 and ASTM F67. We provide material test certificates (MTC) with every order and can accommodate additional certifications upon request.

A: While aluminum is lighter, Grade 1 Titanium Alloy Rod provides greater strength, corrosion resistance, and durability, making it a better option for demanding lightweight applications like aerospace fittings or medical devices.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.