Get in touch with us

Leave a message

Pricing for the Grade 5 Titanium Alloy Bar depends on dimensions, quantity, and specific requirements like surface finish or custom machining. Contact our sales team at sales to get a competitive quote for titanium bars. We provide flexible pricing terms tailored to your needs, whether you are ordering a titanium round bar or a titanium rod for industrial use.

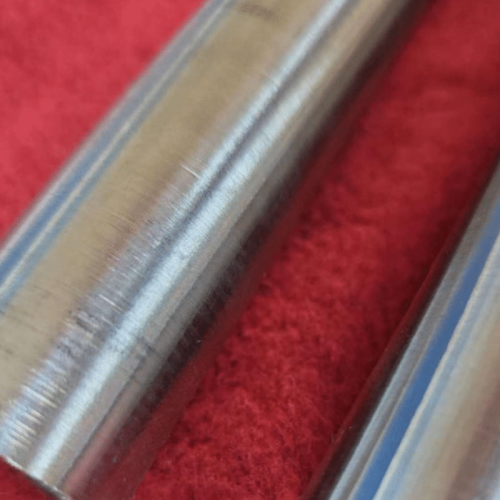

Our Grade 5 Titanium Alloy Bar comes in various configurations:

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | 88.0 - 91.0 |

| Aluminum (Al) | 5.5 - 6.75 |

| Vanadium (V) | 3.5 - 4.5 |

| Iron (Fe) | ≤ 0.40 |

| Oxygen (O) | ≤ 0.20 |

| Carbon (C) | ≤ 0.08 |

| Nitrogen (N) | ≤ 0.05 |

| Property | Value |

|---|---|

| Ultimate Tensile Strength | 895 - 1000 MPa |

| Yield Strength | 828 - 900 MPa |

| Elongation | 10 - 15% |

| Hardness (Rockwell C) | 36 - 38 HRC |

| Modulus of Elasticity | 110 - 120 GPa |

| Environment | Exposure Condition | Corrosion Rate (mm/year) |

|---|---|---|

| Atmospheric (Dry, Urban) | 20°C, 50% RH, 1-year exposure | 0.0005 – 0.001 |

| Atmospheric (Humid, Coastal) | 25°C, 85% RH, 1-year exposure | 0.001 – 0.002 |

| Distilled Water | 25°C, immersion, 30 days | < 0.001 |

| Seawater (3.5% NaCl Solution) | 25°C, immersion, 30 days | 0.002 – 0.005 |

| Dilute Sulfuric Acid (5% H2SO4) | 25°C, immersion, 7 days | 0.005 – 0.010 |

| Concentrated Sulfuric Acid (50%) | 25°C, immersion, 7 days | 0.100 – 0.150 |

| Dilute Sodium Hydroxide (5% NaOH) | 25°C, immersion, 7 days | < 0.001 |

| Hot Sodium Hydroxide (50% NaOH) | 60°C, immersion, 7 days | 0.050 – 0.080 |

| Salt Spray (ASTM B117) | 35°C, 5% NaCl, 96-hour exposure | 0.001 – 0.003 |

| High-Temperature Oxidation | 400°C, air exposure, 100 hours | 0.001 – 0.002 (oxide growth) |

James K.

Aerospace Engineer

Dr. Emily R.

Medical Device Designer

Liam S.

Marine Equipment Supplier

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.