Get in touch with us

Leave a message

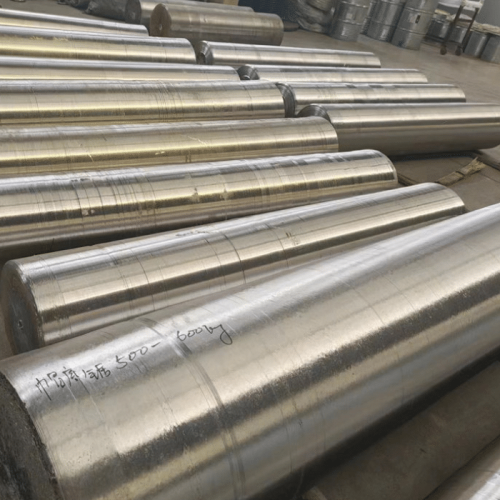

The TA1 Titanium Alloy Bar is a high-performance, pure titanium product renowned for its exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility. Widely used across industries like aerospace, medical, and chemical processing, this bar delivers reliable and durable performance in critical applications.

For detailed pricing or a quote for TA1 Titanium Alloy Bar, please contact us directly. Pricing terms and conditions are tailored to your specific requirements.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | ≥99.5 |

| Iron (Fe) | ≤0.20 |

| Carbon (C) | ≤0.08 |

| Nitrogen (N) | ≤0.03 |

| Hydrogen (H) | ≤0.015 |

| Oxygen (O) | ≤0.18 |

| Property | Value |

|---|---|

| Tensile Strength | ≥240 MPa |

| Yield Strength | ≥170 MPa |

| Elongation | ≥24% |

| Hardness (HB) | ≤120 |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Seawater | <0.01 |

| Atmospheric (Urban) | <0.001 |

| 10% Nitric Acid | <0.05 |

| 5% Hydrochloric Acid | 0.5–1.0 |

Contact us for detailed corrosion resistance data specific to your application.

These TA1 titanium bars are perfect for our lightweight components. Excellent quality and fast delivery from this China manufacturer.

John D.

Aerospace Engineer

The biocompatibility of these titanium rods is unmatched for our implants. Consistent performance every time.

Sarah M.

Medical Supplier

Corrosion resistance in seawater is outstanding. These titanium alloy bars exceeded our expectations.

Mike T.

Marine Contractor

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.