Get in touch with us

Leave a message

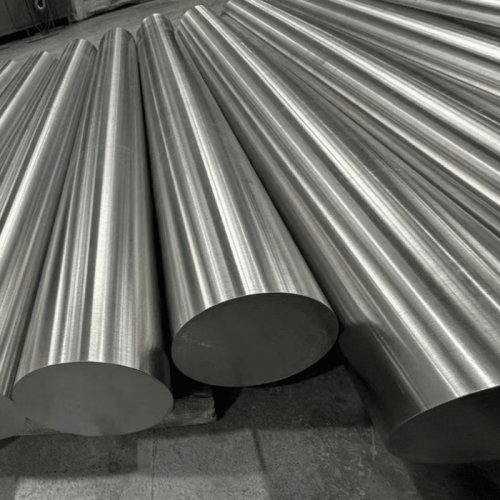

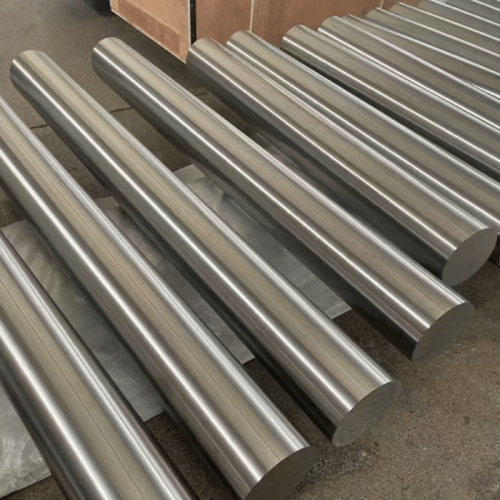

The TA2 Titanium Alloy Rod is a premium-grade titanium product, well-regarded for its exceptional corrosion resistance, lightweight nature, and superior mechanical properties. It is widely used in industries such as aerospace, medical, automotive, and chemical processing due to its reliability and adaptability.

For pricing and inquiries about TA2 Titanium Alloy Rod, contact our team to obtain a competitive quote. Prices are subject to market conditions and available upon request.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | ≥99.2 |

| Iron (Fe) | ≤0.30 |

| Carbon (C) | ≤0.08 |

| Nitrogen (N) | ≤0.03 |

| Hydrogen (H) | ≤0.015 |

| Oxygen (O) | ≤0.25 |

| Property | Value |

|---|---|

| Tensile Strength | ≥345 MPa |

| Yield Strength | ≥275 MPa |

| Elongation | ≥20% |

| Hardness (HB) | ≤160 |

TA2 Titanium Alloy demonstrates excellent resistance to acids, alkalis, and chloride stress corrosion, ensuring long-term performance in chemical and marine environments. Environmental restrictions such as extreme acidity should be carefully evaluated before use.

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Air) | Excellent |

| Seawater | Outstanding |

| Mild Acids | Very Good |

| Strong Oxidizing Acids | Poor |

Contact us for detailed corrosion resistance data specific to your application.

TA2 Titanium Alloy Rod is easily weldable using methods like TIG and MIG welding. It is also highly workable during forming and machining and can be processed efficiently into desired shapes without significant wear on tools.

These titanium rods exceeded our expectations for lightweight strength in our aircraft components.

John D.

Aerospace Engineer

Perfect for medical implants, with excellent biocompatibility and consistent quality.

Sarah M.

Medical Supplier

The corrosion resistance of this titanium bar is unmatched in our seawater applications.

Mike R.

Marine Contractor

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.