Get in touch with us

Leave a message

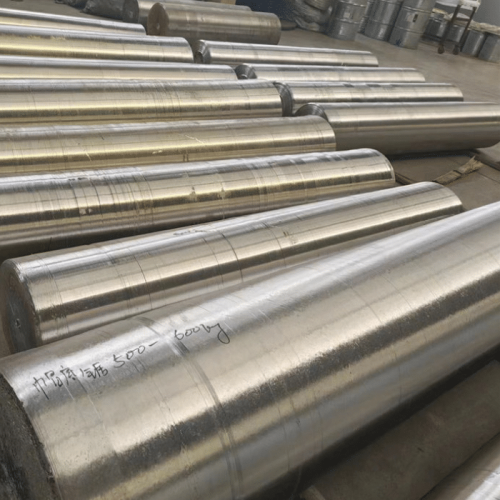

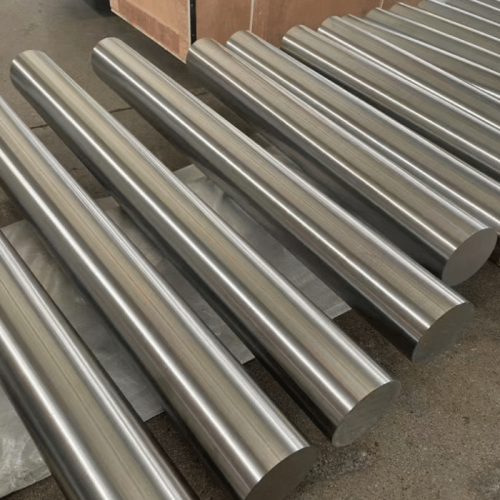

The TA7 Titanium Alloy Rod is a high-strength, corrosion-resistant titanium alloy widely used in aerospace, industrial, medical, and engineering applications. Known for its excellent mechanical properties and biocompatibility, the TA7 alloy is a go-to choice for environments demanding durability, reliability, and resistance to harsh conditions.

For pricing on the TA7 Titanium Alloy Rod, please contact us to obtain a quote and discuss your specific requirements. Pricing terms, including bulk orders and delivery, are available upon inquiry.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 4.5-5.5 |

| Tin (Sn) | 2.0-3.0 |

| lron (Fe) | ≤0.50 |

| 0xygen (0) | ≤0.20 |

| Nitrogen (N) | ≤0.05 |

| Hydrogen (H) | ≤0.015 |

| Property | Value |

|---|---|

| Tensile Strength | ≥900 MPa |

| Yield Strength | ≥830 MPa |

| Elongation | ≥10% |

| Hardness (HB) | 300-350 |

| Density | 4.48 g/cms |

| Environment | Resistance Level |

|---|---|

| Atmospheric | Excellent |

| Seawater | Very Good |

| Mild Acids | Good |

| Strong Acids | Moderate |

| Chlorides (High Temp) | Poor |

Contact us for detailed corrosion resistance data specific to your application.

The TA7 Titanium Alloy Rod is best suited for GTAW (Gas Tungsten Arc Welding) and laser welding techniques. Cold rolling and forging are recommended for shaping, with careful attention to avoid contamination during processing.

The TA7 titanium alloy rod exceeded our expectations in high-stress applications. Reliable and easy to work with!

Johnson L.

Aerospace Engineer

Perfect for our implant manufacturing. The biocompatibility and strength are unmatched.

Rainer P.

Medical Supplier

Consistent quality and great support from this China manufacturer. Highly recommend their titanium bars for sale

Victor D.

Industrial Buyer

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.