Get in touch with us

Leave a message

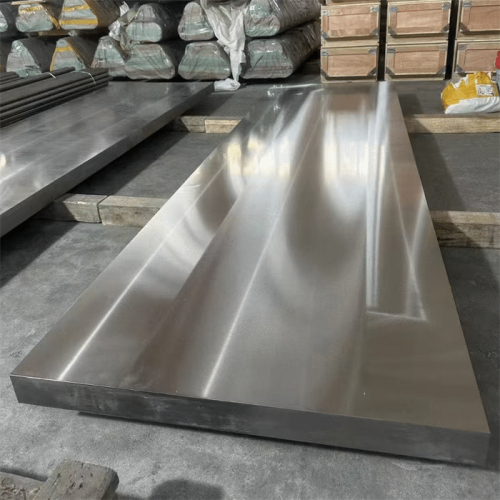

The Grade 5 Titanium Alloy Sheet, also known as Ti Grade 5 or Grade 5 titanium sheet, is a high-strength, lightweight titanium alloy (Ti-6Al-4V) renowned for its excellent corrosion resistance and mechanical properties. It is the most widely used titanium alloy, offering a perfect balance of strength, durability, and workability. As a leading Grade 5 Titanium Alloy Sheet manufacturer in China, we provide premium-quality sheets for industries requiring reliable materials.

For the most competitive pricing on Grade 5 Titanium Alloy Plate, reach out to our sales team directly. We offer customized quotes for Grade 5 Titanium Alloy Sheet price based on your specific requirements, including dimensions, quantity, and delivery timelines. Contact us today to discuss your needs!

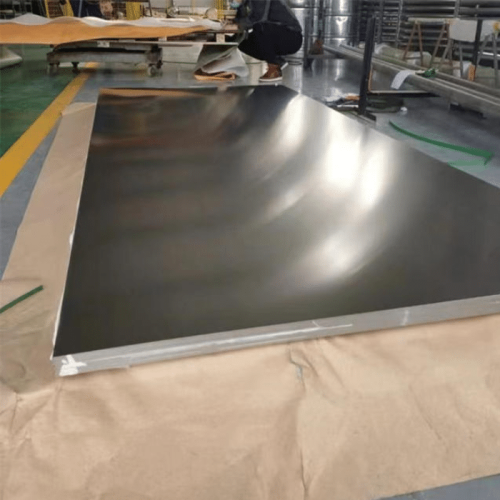

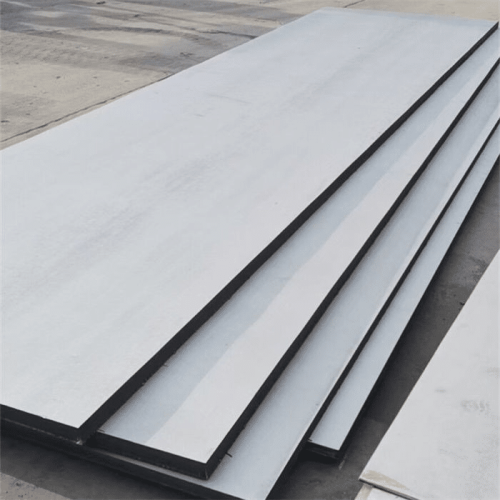

Our Grade 5 Titanium Alloy Plate, including Grade 5 titanium plate and Grade 5 cold rolled titanium sheet, is available in various dimensions and finishes. Below are the typical specifications:

The Grade 5 Titanium Alloy is widely used across industries requiring lightweight, durable materials. Key applications include:

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5–6.75 |

| Vanadium (V) | 3.5–4.5 |

| Iron (Fe) | 0.3 max |

| Oxygen (O) | 0.2 max |

| Carbon (C) | 0.08 max |

| Nitrogen (N) | 0.05 max |

| Property | Value |

|---|---|

| Tensile Strength | 895 MPa (min) |

| Yield Strength (0.2% offset) | 828 MPa (min) |

| Elongation | 10% (min) |

| Hardness (Rockwell C) | 36 HRC (typical) |

| Density | 4.43 g/cm³ |

This Titanium Alloy exhibits excellent resistance to various corrosive environments:

| Environment | Corrosion Rate (mm/year) | Conditions | Notes |

|---|---|---|---|

| Stagnant Seawater | <0.001 | 25°C, 12 months exposure | No pitting observed |

| 5% Sulfuric Acid | 0.02 | 30°C, 3 months exposure | Good resistance in dilute solutions |

| 5% Hydrochloric Acid | 0.05 | 25°C, 1 month exposure | Moderate resistance |

| Atmospheric (Coastal, Humid) | <0.001 | 25°C, 12 months exposure | Excellent resistance |

| 5% Sodium Hydroxide (Alkaline) | <0.002 | 40°C, 3 months exposure | Excellent resistance |

| 5% Nitric Acid | <0.001 | 30°C, 3 months exposure | Superior resistance |

We’ve been using Grade 5 Titanium Alloy Sheet for our surgical implants, and the biocompatibility and strength are exceptional. This China-based manufacturer provided high-quality Grade 5 titanium sheet with precise tolerances. Their support team was fantastic!

Dr. James R.

Medical Device Engineer

The Grade 5 Titanium Alloy Sheet we sourced for our aircraft frames has performed flawlessly. The lightweight strength and corrosion resistance are unmatched, and their Grade 5 titanium plate was delivered on time at a competitive price. Highly recommend!

Liam K.

Aerospace Engineer

We ordered Grade 5 sheets of titanium for our offshore equipment, and the corrosion resistance in seawater is phenomenal. The supplier offered excellent Grade 5 Custom Processing services to meet our exact specifications. Will definitely order again!

Sophie M.

Marine Equipment Supplier

A: Grade 5 Titanium Alloy Sheet (Ti-6Al-4V) offers higher strength than Grade 2 titanium but is less ductile; it’s more versatile than Grade 7 for structural applications.

A: Yes, Ti Grade 5 exhibits excellent corrosion resistance in seawater, making it ideal for marine applications like shipbuilding and offshore equipment.

A: It’s widely used in aerospace, medical, marine, automotive, and chemical processing industries for applications requiring strength and corrosion resistance.

A: Simply contact our sales team with your project details, and we’ll provide a tailored quote for Grade 5 Titanium Alloy Sheet price within 24 hours.

A: Yes, we offer Grade 5 cold rolled titanium sheet in various thicknesses and finishes to meet your specific requirements.

A: We provide Grade 5 titanium plate in hot rolled, cold rolled, pickled, polished, or custom finishes. Contact us to discuss your needs.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.