Get in touch with us

Leave a message

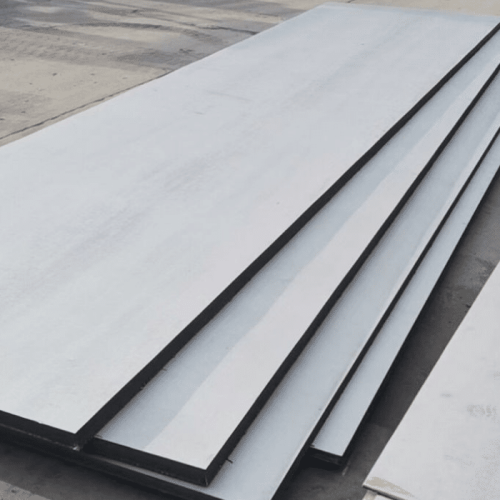

The TA1 Titanium Alloy Sheet, also known as pure titanium, is a high-performance material renowned for its exceptional corrosion resistance, lightweight properties, and durability. Sourced from top titanium alloy manufacturers in China, this titanium sheet is ideal for industries requiring reliable, high-strength materials, such as aerospace, medical, and marine applications.

To obtain precise pricing for the TA1 Titanium Alloy Sheet, please contact our sales team. Pricing is subject to specifications like sheet thickness, quantity, and surface treatment options. Flexible pricing terms are available to meet your needs.

TA1 Titanium Alloy Sheet is widely used in:

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | ≥99.5 |

| Iron (Fe) | ≤0.20 |

| Oxygen (O) | ≤0.18 |

| Carbon (C) | ≤0.08 |

| Nitrogen (N) | ≤0.03 |

| Hydrogen (H) | ≤0.015 |

| Property | Value |

|---|---|

| Tensile Strength | 240-350 MPa |

| Yield Strength | 170-240 MPa |

| Elongation | ≥24% |

| Hardness (HB) | 120-160 |

TA1 Titanium Alloy Sheet offers excellent resistance to acids, alkalis, and salts. It performs well in neutral and mildly acidic environments but may face challenges in highly acidic conditions (e.g., concentrated sulfuric acid). Environmentally, it complies with RoHS standards, ensuring minimal ecological impact.

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Urban/Rural) | Excellent |

| Seawater | Outstanding |

| Mild Acids (e.g., Acetic Acid) | Good |

| Strong Acids (e.g., Sulfuric Acid) | Moderate |

Recommended welding methods for TA1 Titanium Alloy Sheet include TIG (Tungsten Inert Gas) and plasma arc welding. Use filler materials compatible with pure titanium. Forming techniques like bending and cutting are achievable with proper tools, ensuring precision in custom processing.

The TA1 Titanium Alloy Sheet from this China manufacturer exceeded our expectations for airframe components. Lightweight and durable!

John D.

Aerospace Engineer

Perfect for medical implants. The titanium sheet’s biocompatibility and custom processing options are top-notch.

Lisa M.

Medical Device Manufacturer

Outstanding corrosion resistance in seawater. These sheets of titanium are a game-changer for our offshore projects.

Michael R.

Marine Equipment Supplier

A: TA1 is a commercially pure titanium grade, offering superior corrosion resistance and biocompatibility compared to alloyed titanium grades.

A: Yes, TA1 titanium is biocompatible, making it ideal for implants and surgical equipment.

A: TA1 can handle moderately high temperatures under oxidizing conditions but may require caution in extreme heat.

A: Aerospace, marine, medical, chemical processing, and architecture industries find the most value in TA1 sheets.

A: Certifications include ISO, ASTM standards, and material testing reports.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.