Get in touch with us

Leave a message

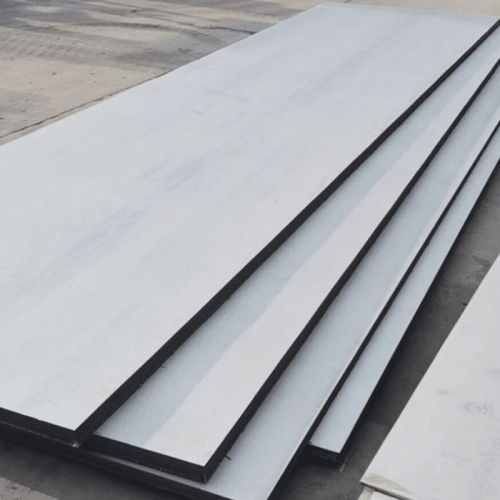

The TA15 Titanium Alloy Plate is a high-performance material designed for demanding industrial applications. Renowned for its exceptional strength-to-weight ratio, corrosion resistance, and excellent weldability, this alloy plate is an ideal choice for various industries, including aerospace, automotive, marine, and medical sectors. Its ability to withstand high temperatures and harsh environments makes it a preferred material for manufacturing components that require durability and reliability.

For pricing inquiries regarding the TA9 Titanium Alloy Sheet, please contact us directly. Pricing depends on size, quantity, and specific requirements. Competitive terms and bulk order options are available to meet your needs.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5–7.0 |

| Molybdenum (Mo) | 0.5–2.0 |

| Zirconium (Zr) | 1.5–2.5 |

| Iron (Fe) | ≤0.25 |

| Property | Value |

|---|---|

| Tensile Strength | ≥980 MPa |

| Yield Strength | ≥900 MPa |

| Elongation | ≥8% |

| Hardness (HB) | 320–360 |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric | <0.01 |

| Seawater | <0.02 |

| Mild Acids | <0.04 |

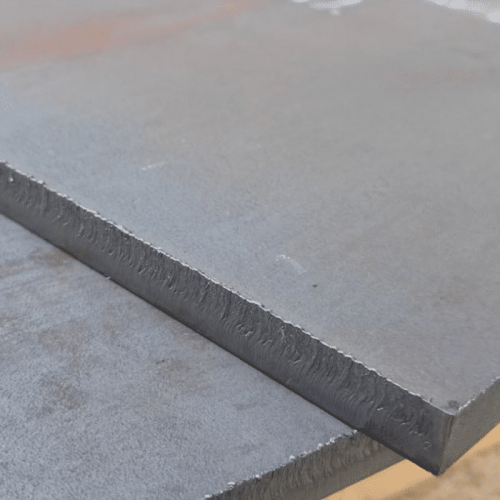

TA15 Titanium Alloy Plate can be welded using methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Cold rolling and forming techniques are suitable for achieving the desired shapes and dimensions. Pre-heating is recommended for thicker plates to avoid cracking during the welding process.

TA15 Titanium Alloy Plate is perfect for high-stress aircraft components.

Mark B.

Aerospace Engineer

Reliable titanium metal plate for our chemical processing equipment.

Lisa K.

Industrial Buyer

TA15’s titanium alloy composition ensures durability in tough conditions.

James P.

Defense Contractor

A: TA15 has aluminum and vanadium additions, enhancing strength and temperature resistance compared to pure titanium.

A: Yes, its biocompatibility and corrosion resistance make it a reliable choice for medical applications.

A: TA15 offers a balance between strength, weight, and weldability, making it versatile for many industries.

A: Yes, dimensions such as thickness and width can be tailored to meet specific project requirements.

A: It performs reliably in temperatures up to 500°C.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.