Get in touch with us

Leave a message

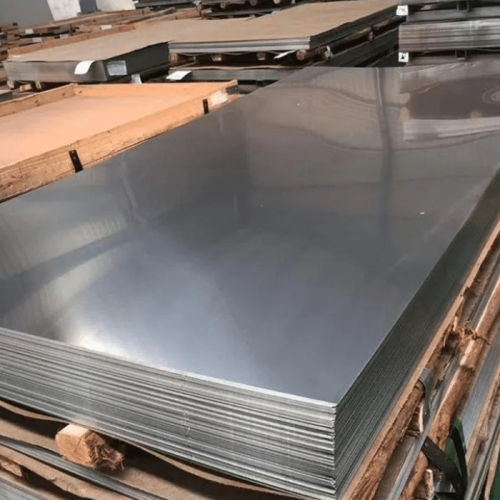

The TA3 Titanium Alloy Sheet, a premium titanium plate, offers exceptional strength, lightweight properties, and corrosion resistance. Manufactured in China, this titanium metal plate is ideal for industries requiring high-performance materials, such as aerospace, medical implants, and marine applications. Its versatility and durability make it a top choice among titanium alloy manufacturers.

For pricing inquiries regarding the TA3 Titanium Alloy Sheet, please contact us for a customized quote. Pricing is based on volume, dimensions, and specific requirements. Terms like “FOB” and “CIF” are available for your convenience.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | ≥99.0 |

| Iron (Fe) | ≤0.30 |

| Carbon (C) | ≤0.08 |

| Nitrogen (N) | ≤0.05 |

| Hydrogen (H) | ≤0.015 |

| Oxygen (O) | ≤0.35 |

| Property | Value |

|---|---|

| Tensile Strength | ≥485 MPa |

| Yield Strength | ≥345 MPa |

| Elongation | ≥20% |

| Hardness (HB) | ≤160 |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | <0.01 |

| 10% Sulfuric Acid | 0.02-0.05 |

| 5% Sodium Hydroxide | <0.01 |

Our aerospace project benefited from the lightweight and durable TA3 Titanium Alloy Sheet. Excellent quality from this China manufacturer!

Lina P.

Aerospace Engineer

Perfect for medical implants. The titanium metal alloy’s biocompatibility is top-notch, and the supplier was reliable.

Andy K.

Medical Device Manufacturer

The titanium sheet’s corrosion resistance is impressive in marine environments. Highly recommend for offshore applications.

Bruce F.

Marine Contractor

A: TA3 offers similar corrosion resistance with enhanced strength and machinability compared to pure titanium.

A: Yes, its biocompatibility makes it an excellent choice for implants.

A: TIG welding is highly suggested for superior joint quality.

A: TA3 performs reliably across a wide temperature range and harsh chemical environments, but caution is advised above 650°C.

A: Available in thicknesses ranging from 0.5mm to 100mm, with customizable widths and surface treatments.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.