Get in touch with us

Leave a message

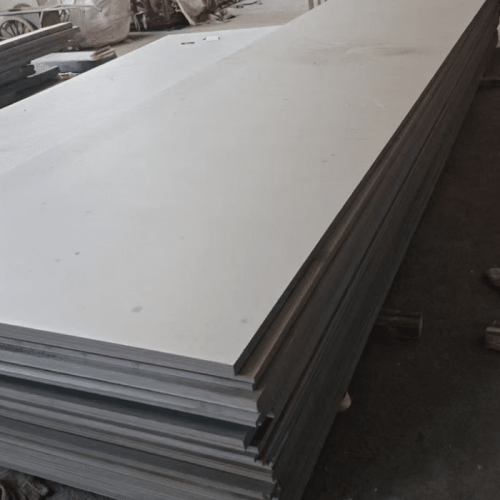

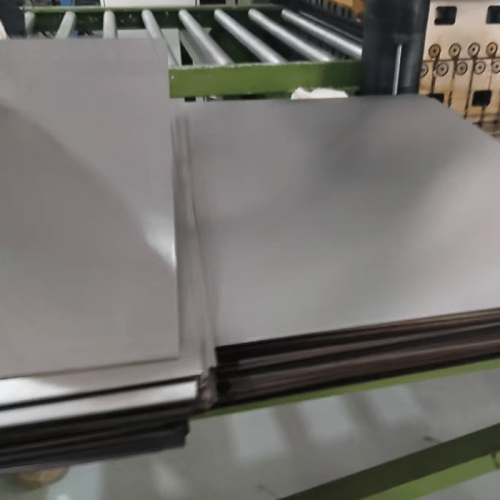

The TA7 Titanium Alloy Plate is a high-performance material known for its exceptional strength, corrosion resistance, and biocompatibility. Widely used across industries such as aerospace, marine, chemical processing, and medical implants, this alloy delivers unmatched functionality in both high-stress and chemically harsh environments.

To inquire about the price of TA7 Titanium Alloy Plate, please contact us directly for a tailored quote. Pricing terms for TA7 Titanium Alloy Plates depend on specifications such as thickness, width, and required surface treatment.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.0–6.0 |

| Tin (Sn) | 2.0–3.0 |

| Iron (Fe) | ≤0.25 |

| Oxygen (O) | ≤0.20 |

| Property | Value |

|---|---|

| Tensile Strength | ≥900 MPa |

| Yield Strength | ≥830 MPa |

| Elongation | ≥10% |

| Hardness (HB) | 300–340 |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric | <0.01 |

| Seawater | <0.02 |

| Mild Acids | <0.05 |

TA7 Titanium Alloy Plate exceeded expectations for our aircraft components. Reliable and lightweight.

John D.

Aerospace Engineer

Perfect for medical implants. The titanium alloy composition ensures biocompatibility.

Emily S.

Medical Supplier

Durable titanium metal plate for our chemical plant. Great corrosion resistance.

Michael T.

Industrial Manager

A: TA7 offers a unique combination of strength, corrosion resistance, and biocompatibility, making it superior for many demanding applications.

A: Yes, TA7 is highly resistant to seawater corrosion, making it an excellent choice for marine environments.

A: TA7 can be successfully welded using specialized methods like TIG or electron beam welding.

A: Aerospace, marine, medical, automotive, and chemical processing industries are among the top users of TA7.

A: While TA7 is generally more expensive, its superior properties justify the cost for high-performance applications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.