Get in touch with us

Leave a message

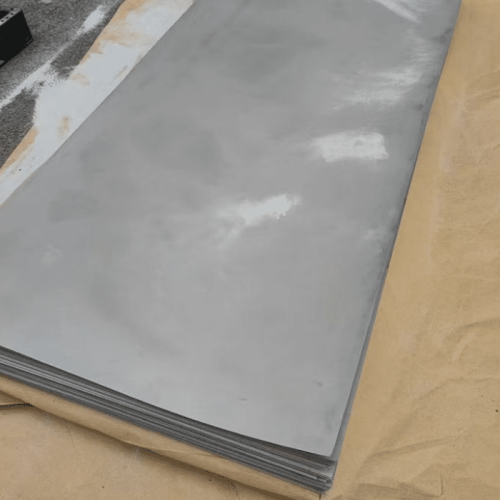

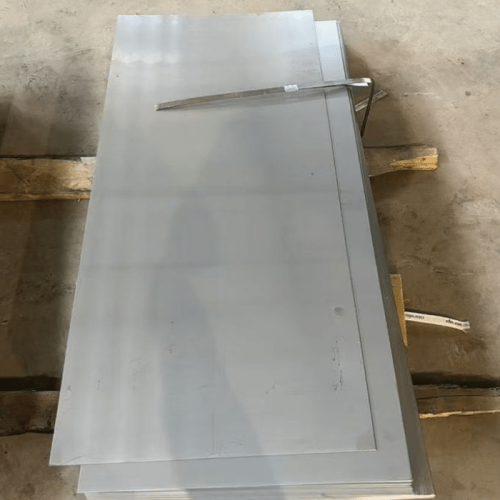

The TA9 Titanium Alloy Sheet is a high-performance material known for its excellent corrosion resistance, lightweight properties, and impressive strength. Widely used in industries such as aerospace, marine, and medical applications, this alloy is ideal for environments requiring durability and reliability under extreme conditions.

For pricing inquiries regarding the TA9 Titanium Alloy Sheet, please contact us directly. Pricing depends on size, quantity, and specific requirements. Competitive terms and bulk order options are available to meet your needs.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Palladium (Pd) | 0.12–0.25 |

| Iron (Fe) | ≤0.30 |

| Oxygen (O) | ≤0.25 |

| Carbon (C) | ≤0.08 |

| Property | Value |

|---|---|

| Tensile Strength | ≥430 MPa |

| Yield Strength | ≥380 MPa |

| Elongation | ≥20% |

| Hardness (HB) | 200–250 |

The TA9 Titanium Alloy Sheet is resistant to a variety of acids, including nitric acid and organic acids. The material demonstrates superior alkali resistance and withstands chloride-rich environments, making it ideal for chemical and marine applications.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric | <0.01 |

| Seawater | <0.01 |

| Mild Acids | <0.03 |

TA9 Titanium Alloy Sheet is lightweight and reliable for our aircraft parts.

Anna L.

Aerospace Technician

Great for medical implants due to its titanium alloy composition.

David R.

Medical Manufacturer

TA9 titanium metal plate performs well in corrosive marine environments.

Sarah M.

Marine Engineer

A: TA9 offers superior corrosion resistance and biocompatibility compared to other grades, making it ideal for medical and marine applications.

A: While TA9 performs well at moderately high temperatures, prolonged exposure to extreme heat may reduce its strength.

A: Yes, dimensions such as thickness, width, and length can be customized to meet your specific requirements.

A: Manufactured in China by trusted and certified factories with rigorous quality assurance standards.

A: Industries such as aerospace, marine, medical, and chemical processing extensively use TA9 for its unique properties.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.