Get in touch with us

Leave a message

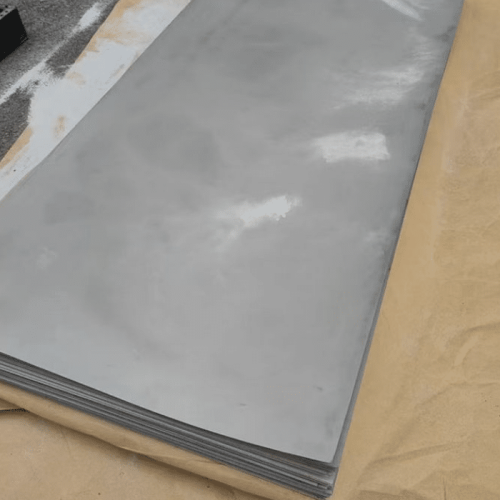

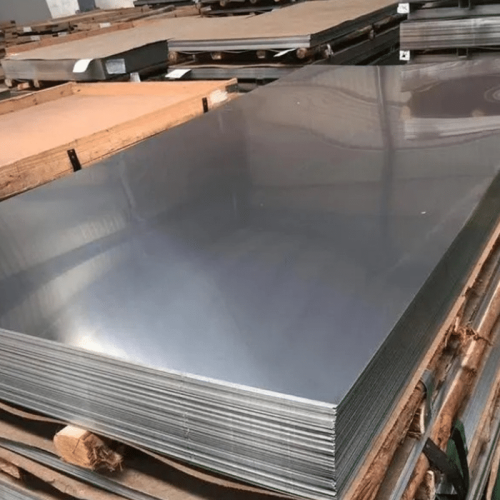

The TC11 Titanium Alloy Plate is a high-performance material widely used in aerospace, medical implants, chemical processing, and energy industries. Recognized for its exceptional strength, corrosion resistance, and lightweight nature, this titanium alloy offers superior mechanical properties, making it ideal for demanding environments.

For pricing details or to obtain a quote for the TC11 Titanium Alloy Plate, please contact our enterprise directly. Pricing terms, including bulk orders, customization options, and delivery specifics, are available upon request.

The TC11 Titanium Alloy Plate is commonly utilized in the following applications and industries:

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5-6.5 |

| Molybdenum (Mo) | 1.5-2.5 |

| Zirconium (Zr) | 0.8-2.0 |

| Silicon (Si) | 0.15-0.40 |

| Iron (Fe) | ≤0.25 |

| Property | Value |

|---|---|

| Tensile Strength | ≥900 MPa |

| Yield Strength | ≥830 MPa |

| Elongation | ≥10% |

| Hardness (HB) | 300-340 |

| Environment | Resistance |

|---|---|

| Atmospheric (Urban) | Excellent |

| Seawater | Excellent |

| Mild Acids | Good |

| Strong Acids | Moderate (coating recommended) |

The TC11 titanium metal plate from this China manufacturer exceeded our expectations for aerospace components. Highly durable!

Anthony Q.

Aerospace Engineer

Perfect for medical implants. The titanium alloy composition ensures biocompatibility and strength.

Karina P.

Medical Device Manufacturer

Reliable sheets of titanium for our marine projects. Corrosion resistance is top-notch.

Kati B.

Marine Equipment Supplier

A: The TC11 alloy combines lightweight properties with enhanced strength and heat resistance, which pure titanium lacks.

A: Yes, but it is typically limited to operating conditions below 600°C.

A: It offers a balance of mechanical strength and corrosion resistance, making it ideal for aerospace and industrial applications.

A: Standard treatments include polishing, pickling, and anodization for improved surface properties.

A: Yes, dimensions, thickness, and surface finishes can be tailored according to client specifications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.