Get in touch with us

Leave a message

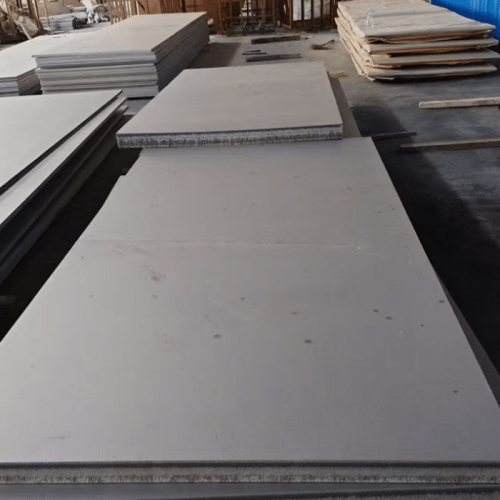

TC21 Titanium Alloy Plate is a high-strength, lightweight solution commonly used in demanding industries such as aerospace, medical implants, and automotive manufacturing. Recognized for its exceptional corrosion resistance, excellent weldability, and superior mechanical properties, it is perfect for environments requiring top-notch performance and durability.

For pricing details on TC21 Titanium Alloy Plate, please contact us to request a quote. Pricing terms are based on product specifications, bulk order requirements, and delivery preferences.

TC21 Titanium Alloy Plate is utilized across various sectors, including but not limited to the following industries:

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5-6.5 |

| Zirconium (Zr) | 1.8-2.2 |

| Molybdenum (Mo) | 1.5-2.5 |

| Niobium (Nb) | 2.0-3.0 |

| Chromium (Cr) | 0.8-1.2 |

| Property | Value |

|---|---|

| Tensile Strength | 1100-1200 MPa |

| Yield Strength | 950-1050 MPa |

| Elongation | 10-15% |

| Hardness | HB 300-350 |

TC21 Titanium Alloy offers exceptional resistance to acids, alkalis, and chloride environments. It can maintain stability and performance in temperatures up to 600°C, making it ideal for high-stress operating conditions. However, care should be taken to avoid long-term exposure to extreme cyclic heat cycles.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | <0.02 |

| 10% Sulfuric Acid | 0.05-0.1 |

| 5% Sodium Hydroxide | <0.03 |

TC21 Titanium Alloy Plate exhibits excellent weldability via methods such as TIG (Tungsten-Inert Gas) welding and laser welding. Additionally, its enhanced ductility allows for various forming techniques like bending, spinning, and stamping. Preheating is generally unnecessary, but post-weld heat treatment is recommended for stress relief.

We've been using TC21 Titanium Alloy Plates for aerospace component production, and the results are outstanding! The strength and reliability are top-notch.

Susan L.

Aerospace Manufacturer

The surface quality of the TC21 plates is remarkable. It meets our high standards for medical applications.

Vida K.

Medical Supplier

Highly recommend this product due to its excellent corrosion resistance and versatility!

Mike D.

Industrial Buyer

A: TC21 offers a unique combination of high tensile and yield strength alongside exceptional corrosion resistance, setting it apart for demanding applications.

A: Yes, TC21 Titanium Alloy is highly resistant to saltwater corrosion and ideal for marine environments.

A: Yes, TC21 Titanium Alloy Plates can be tailored to meet specific dimensions based on your project requirements.

A: Laser welding, TIG welding, and cold forming are preferred methods. Post-fabrication heat treatment is also recommended for stress relief.

A: Yes, it is commonly used in medical implants due to its biocompatibility and excellent mechanical stability.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.