Get in touch with us

Leave a message

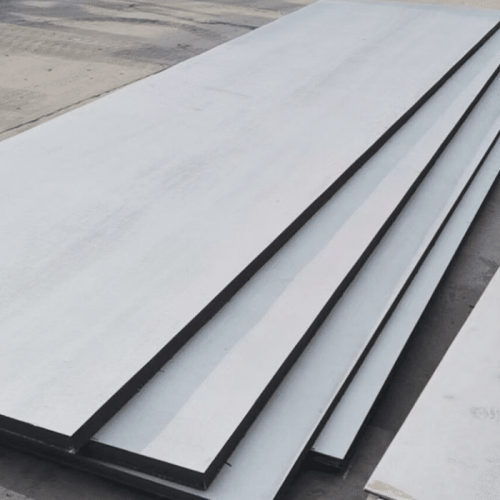

The TC6 Titanium Alloy Plate is a high-performance material ideal for demanding applications in industries such as aerospace, medical equipment, and marine engineering. This alloy is known for its excellent combination of strength, corrosion resistance, and lightweight properties, making it a preferred choice for projects requiring reliability and durability.

Request a Quote: For pricing details and terms on TC6 Titanium Alloy Plate, please contact us directly. Pricing is based on specifications and order requirements.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5 - 6.5 |

| Molybdenum (Mo) | 1.5 - 2.5 |

| Vanadium (V) | 0.8 - 2.0 |

| Iron (Fe) | ≤ 0.5 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 900 MPa |

| Yield Strength | ≥ 830 MPa |

| Elongation | ≥ 10% |

| Hardness (HB) | 300 - 350 |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | < 0.01 |

| Seawater | < 0.02 |

| Mild Acidic Solutions | 0.01 - 0.05 |

The TC6 Titanium Alloy Plate from this China manufacturer exceeded our expectations for aircraft components. Excellent quality and delivery.

John D.

Aerospace Engineer

Perfect for medical implants. The titanium sheet’s biocompatibility and precision are top-notch.

Lisa M.

Medical Device Supplier

Reliable titanium metal plate for offshore projects. Corrosion resistance is outstanding.

Mark T.

Marine Contractor

A: TC6 offers significantly higher strength and better corrosion resistance compared to pure titanium, making it suitable for demanding industrial applications.

A: Yes, TC6 titanium alloy meets the requirements for medical-grade materials such as implants and surgical devices.

A: TC6 balances high strength, moderate ductility, and corrosion resistance, ideal for applications like aerospace and marine engineering.

A: Cold rolling, annealing, and TIG/MIG welding are most effective for this alloy.

A: Yes, but performance may decrease at temperatures exceeding 400°C.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.