Get in touch with us

Leave a message

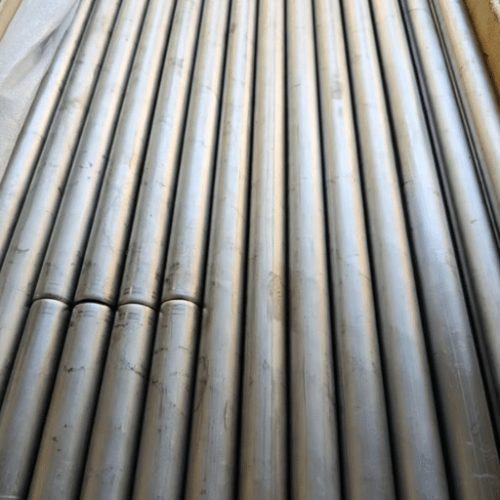

TA1 Titanium Alloy Pipe is a premium-grade material known for its exceptional strength, corrosion resistance, and lightweight properties. Widely used in aerospace, medical, and industrial equipment, it is ideal for applications requiring durability and precision. Its versatility ensures performance in demanding environments while maintaining structural integrity.

For pricing details on TA1 Titanium Alloy Pipe, please contact our sales team. Prices are available upon request and terms can be customized to meet your specific needs.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | ≥99.5 |

| lron (Fe) | ≤ 0.20 |

| Carbon (C) | ≤ 0.08 |

| Nitrogen (N) | ≤ 0.03 |

| Hydrogen (H) | ≤ 0.015 |

| Oxygen (O) | ≤ 0.25 |

| Property | Value |

|---|---|

| Tensile Strength | >240 MPa |

| Yield Strength | > 170 MPa |

| Elongation | >24% |

| Hardness (Brinell) | ≤ 120 HB |

| Density | 4.51 g/cm³ |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Seawater | <0.01 |

| Nitric Acid (10%) | 0.05 |

| Sulfuric Acid (5%) | 0.1 |

| Sodium Hydroxide (10%) | 0.02 |

Contact us for detailed corrosion resistance data specific to your application.

We've been using TA1 Titanium Alloy Pipe for our hydraulic systems. The lightweight and strength are unbeatable, and the corrosion resistance ensures longevity.

Cady L.

Aerospace Engineer

This titanium tubing has significantly reduced our maintenance costs. It’s resistant to the harsh chemicals we handle daily.

Edward T.

Chemical Plant Manager

These titanium bars for sale withstand harsh seawater conditions perfectly. Highly recommend this distributor.

Kate W.

Marine Contractor

A: TA1 is a commercially pure grade with superior corrosion resistance and strength, making it ideal for critical applications.

A: TA1 performs well in moderately high temperatures, but not in excessively high thermal environments.

A: Yes, it is biocompatible and widely used for implants and surgical instruments.

A: Yes, the pipe can be manufactured to meet specific dimensional and surface requirements.

A: TA1 is significantly lighter than steel while maintaining excellent strength.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.