Sectors of the modern economy have an unparalleled focus on materials that are light, tough, and can withstand extreme conditions. This attention is given to ultra-high strength steel (UHSS), which is considered a revolutionary development of steel industry products. UHSS is already being used and developed in automotive manufacturing and infrastructure due to the synergistic need for efficiency, sustainability, and durable structural strength.

This post focuses on ultra-high-strength steel, its creation, unique properties, core advantages, and underlying technologies. It also covers its anticipated growth across industries, including why its advanced high-strength steel products are deemed ultra-high strength. If you’re a material science aficionado or simply someone baffled by what is shaping engineering and manufacturing, this is your guide.

What is Ultra High Strength Steel?

Ultra-high-strength steel (UHSS) is an advanced class of steel materials developed to have particularly high strength and exceptional durability. To create its high-performance UHSS steel, it undergoes processes like alloying and heat treatment, tailored to focus on the material’s performance under stress or load. This type of steel is commonly used in low-weight automotive, aerospace, construction sectors, and other industries where high strength combined with a lightweight frame is necessary for safety.

Characteristics and Properties of UHSS

Ultra High Strength Steel (UHSS) is known for its remarkable tensile strength, generally over 780 MPa, and varying grades can go as high as 1,500 MPa or more. Exceeding this limit is attributed to advanced manufacturing practices such as precision alloying and thermomechanical processing, which include the production of martensite, bainite, and dual-phase microstructures. Not only does UHSS provide unmatched strength, but it also undergoes incredible strain due to its exceptional energy-absorbing capacity, formability, and stress resistance. This creates the ideal material for applications where the highest level of safety is crucial.

The most recent data about the industry exhibits a fast cross-sector adoption of Ultra High Strength Steel (UHSS), driven mainly by the lightweight and robust materials. We can take the automotive industry as an example, where the adoption of UHSS has skyrocketed in the past decade. At the same time, industries are using ultra-high-strength steel (UHSS) to reduce the vehicle’s weight and increase fuel economy without compromising strength. They say that advanced grades of ultra-high-strength steel are associated with more than a 25 percent reduction in essential parts of fuel-efficient vehicles, which is an increase compared to traditional steels. This enables the vehicle to consume less energy, decreasing emissions significantly.

Applications of UHSS Across Industries

While the automotive industry is one of the most critical sectors, construction and space technology are also two industries where UHSS is important. Modern skyscrapers use UHSS for some of the most essential building parts to support incredibly high amounts of force while saving material. For the airspace, UHSS is necessary for the parts directly linked to the mechanical stress, but the weight of the jet is kept low to increase performance. The thinner the material is, the more planes can be used. The standardized tests done under ASTM and ISO certifications also proved that the materials are reliable and adaptable.

Because sustainability is a crucial issue worldwide, materials consumption and energy efficiency are UHSS engineering priorities. Their lifecycle performance is unmatched, and they exhibit extremely high recyclability, meaning UHSS is always one step ahead in cutting-edge sustainable materials innovations.

The Evolution of High-Strength Steel

| Era | Key Development | Applications | Key Features |

|---|---|---|---|

| 1960s-1970s | Introduction of dual-phase steels | Automotive, aircraft components | Improved strength, limited formability |

| 1980s | Advanced metallurgy techniques | Structural and safety components | Enhanced crash resistance |

| 1990s | Ultra Light Steel Auto Body project | Lightweight vehicles | Weight reduction, safety focus |

| 2000s | TRIP and DP steels | Automotive, construction | High ductility, energy absorption |

| 2010s | Ultra-high strength steels (UHSS) | Aerospace, energy sector | Superior strength-to-weight ratio |

| 2020s | Sustainability and recyclability focus | All industries | Eco-friendly, cost-efficient |

Comparing AHSS and UHSS Steel Grades

| Parameter | AHSS | UHSS |

|---|---|---|

| Yield Strength | ≥ 550 MPa | ≥ 780 MPa |

| Tensile Strength | 500-800 MPa | ≥ 780 MPa |

| Microstructure | Multiphase (ferrite, martensite, etc.) | Engineered for ultra-high strength |

| Ductility | High, good for forming | Lower, optimized for strength |

| Applications | Automotive body structures | Safety-critical automotive components |

| Weight Reduction | Up to 25% | Higher potential with thinner sections |

| Crash Performance | High energy absorption | Superior crash resistance |

| Recyclability | Fully recyclable | Fully recyclable |

| Cost | Moderate | Higher due to advanced processing |

Why is Ultra-High Strength Steel Important?

Ultra-high-strength steel has a unique importance because it permits lighter and stronger structures and designs in the automotive industry. It enhances fuel efficiency, reduces emissions, and improves the strength-to-weight ratio of vehicles. It also enhances the safety provisions of modern vehicles. The manufacturing of light-weight vehicles is in demand at the time, and using ultra-high-strength steel permits designs in vehicles without compromising on safety. Further, the eco-friendly cars can be designed because of the sancentric approach and ease of recycling in ultra-high-strength steel.

Mechanical Properties and Tensile Strength of UHSS

| Parameter | Details |

|---|---|

| Tensile Strength | ≥ 700 MPa |

| Yield Strength | 500-700 MPa |

| Elongation | 10-20% |

| Hardness | 200-300 HB |

| Density | 7.85 g/cm³ |

| Thermal Conductivity | 50 W/m·K |

| Corrosion Resistance | Fair, susceptible to pitting |

| Formability | Good, with work hardening limitations |

| Weldability | Moderate, requires specialized techniques |

| Applications | Automotive, aerospace, construction |

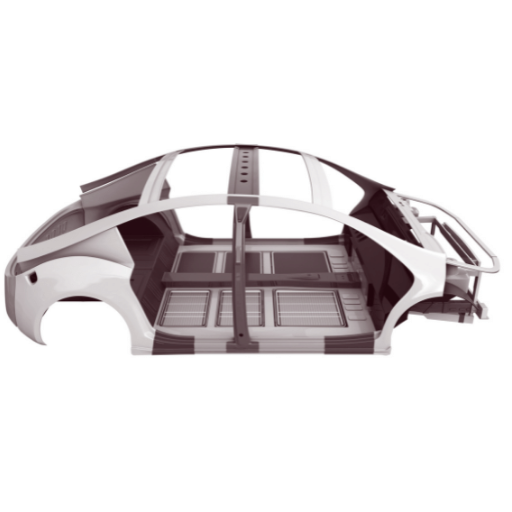

The Role of UHSS in the Automotive Industry

Ultra high-strength steel, or UHSS, has transformed the automobile industry by streamlining vehicles to make them lighter, safer, and more environmentally friendly. Below is a detailed breakdown of its benefits and applications, together with specific data points:

- Best Fuel Effeciency Rates

Because of UHSS’s high strength-to-weight ratio, manufacturers can reduce vehicle weight by 25 percent compared to other traditional steels. Using UHSS components improves fuel efficiency by up to 6 to 8 percent, significantly decreasing CO2 emissions.

- Durability

The tensile strength of UHSS is astounding, exceeding 1200 MPa, which also greatly improves crash resistance. Vehicles that incorporate UHSS into critical areas of their structure perform better during crashes, improving impact absorption and greatly increasing the safety of people in the vehicle.

- Corrosion Resistance

The more modern coatings on UHSS make it resistant to environmental factors such as salt and moisture, making vehicle components significantly more durable and reducing the need for repairs over a long period of time.

- Sustainability

In terms of sustainability aspects, UHSS stands out among steel types because it is 100 percent recyclable and degenerates negligibly with dough recycling. This is greatly needed in the automotive industry and adheres to difficult global standards of sustainability.

- Cost Efficiency Due To Material Optimisation

Although more expensive upfront, the UHSS’s lightweight and durable characteristics lower total production and operations costs over the vehicle’s lifetime.

With these properties, UHSS continues to enable further innovation in automobile design and performance while addressing safety and environmental issues.

High-Strength Steels Advantages Over Conventional Steels

| Parameter | High-Strength Steel Advantage |

|---|---|

| Strength-to-Weight Ratio | Higher, enabling lighter structures |

| Durability | Greater resistance to wear and fatigue |

| Corrosion Resistance | Improved in many high-strength grades |

| Environmental Impact | Reduces material use and CO₂ emissions |

| Design Flexibility | Allows innovative and complex designs |

| Cost Efficiency | Long-term savings despite higher upfront cost |

| Safety | Superior crash and impact resistance |

| Recyclability | Fully recyclable, promoting sustainability |

| Construction Speed | Prefabrication reduces build time |

| Load Capacity | Supports heavier loads with less material |

How Does Formability Affect UHSS?

The formability of steel is the primary factor in determining the application of ultra-high-strength steel in modern manufacturing processes. UHSS can be used on other mobile structures where the materials can be formed into stable locked units without deformation strains or cracking. The intricate designs can benefit from better formability. Despite the lower formability of UHSS than that of conventional steels, it has tremendous opportunities when dealing with hot stamping techniques. Formability and strength go hand in hand when optimal usage of the ultrahigh-strength steel is mandated. With the delicate balance of the two, the use in automobiles and other highly resistant performance structures can be implemented.

Balancing Strength and Ductility in UHSS

| Parameter | Details |

|---|---|

| Strength-Ductility Synergy | Achieved via nanoprecipitate engineering |

| Key Phases | Martensite, bainite, retained austenite |

| Thermal Treatments | Duplex aging enhances properties |

| Nanoprecipitates Role | Strengthen and delay deformation |

| Austenite Stability | Improves ductility through TRIP effect |

| Yield Strength | Up to 1876 MPa |

| Tensile Strength | Up to 2259 MPa |

| Elongation | Approximately 11.5% |

| Applications | Aerospace, automotive, defense |

| Challenges | Balancing cost and processing complexity |

The Challenge of Elongation in High-Strength Steels

The problem with high-strength steels’ elongation is their structural balancing. The strongest clue is that alloy design and advanced processing involve heat treating or engineering the microstructure. With these optimizations, it is possible to increase elongation without loss to stiffness of the material.

Innovations in Formability for UHSS

New hot stamp and tailor-made tempering processes, which increase ductility without losing UHSS strength properties, improve the formability potential of ultra-high-strength steels( UHSS).

What are the Applications of Ultra-High Strength Steel?

Ultra-high-strength steel (UHSS) is popular in ultra-demanding and durable industries. Some of the most relevant include:

- Automotive Industry UHSS is used in vehicle structures and parts to improve crash safety without adding weight, further improving fuel efficiency.

- Construction Industry Due to its greater strength and load-bearing capacity, it also applies in building frameworks and infrastructure projects.

- Aerospace Sector UHSS is used for critical parts that must be lightweight and strong simultaneously.

- Energy Sector Involved in the construction of pipelines and parts of renewable energy systems such as wind turbines.

Automotive Industry Benefits from UHSS

The automotive industry is one of the many fields which have adopted Ultra High-Strength Steel (UHSS) as its primary component due to its strength, durability, and lightweight nature. Below is a detailed summary of its impact and its five key benefits:

- Better Crash Safety: Vehicles made from UHSS have greatly improved vehicle safety due to their better absorption of crash energy. In more serious collisions, vehicles made with UHSS parts can reduce casualties by 20%.

- Lower Vehicle Weight: UHSS permits the use of weaker, thinner structures without compromising strength, which helps lower the vehicle’s weight. The reduced weight enhances fuel economy by as much as 5 -10 percent.

- Increased Durability: The wear and tear and corrosion resistance offered by UHSS lead to lower maintenance costs over the lifespan of the vehicle components.

- Increased Design Flexibility: Innovative complex vehicle designs are increasingly made possible by UHSS due to thinner profiles. Neither functionality nor aesthetics is a concern since the automobile is not burdened by additional weight.

- Reduced UHSS Carbon Footprint: Vehicles become significantly lighter, enhancing fuel economy and reducing CO2 emissions throughout their lifetime. The use of UHSS improves vehicles’ overall carbon footprint and allows for a cleaner environment.

Construction and Infrastructure Uses

Ultra-high-strength steel (UHSS) is one of the latest innovations used in automobiles and construction systems. Its high strength-to-weight ratio and durability make it ideal for demanding applications where structural integrity is needed.

- Structural Applications: Skyscrapers, bridges, and skyscraper public buildings are all examples of structures that employ and are expected to increasingly rely on UHSS. For instance, research estimates that using UHSS in high-rise construction can save steel and cost by 30% and lessen overall environmental impact.

- Seismic Resistance: In areas most susceptible to earthquakes, standing Ultra-High Strength Steel would serve the best due to the material’s capability of absorbing massive amounts of energy. Additionally, advanced grades of UHSS improve structural stability under high stress, thereby reducing damage to critical infrastructure.

- Durability in Extreme Conditions: UHSS structures can endure extremely harsh environments like high load, extremes of temperature, and corrosion. Moreover, studies suggest such steel structures have a lifespan upto 20% more than ordinary steel, which saves time on maintenance due to its durability.

- Sustainability: This steel makes lighter elemental structures possible, which saves cost for these components during transportation and assembly. In addition, UHSS is recyclable, which means it can be used in green building construction, contributing to the Sustainable Development Goals.

Such benefits make UHSS an essential material in modern construction. It supports not only innovation but also efficiency and resilience against emerging structural challenges.

Future Applications of Ultra-High Strength Materials

The applications of Ultra-High Strength Materials (UHSS) continue to expand because of their benefits, which include weight reduction and endurance to extreme conditions. Listed below are three current and future uses of UHSS and how they can innovate:

- Aerospace Engineering

The average strength-to-weight ratio of UHSS makes it highly valuable in aerospace engineering. It improves the aircraft’s durability while significantly reducing the overall weight. With the addition of UHSS to air vehicles, ongoing studies suggest a potential 15% boost in their overall efficiency. As a result, fuel economy improves and payload capacity increases.

- Skyscrapers and High-Rise Buildings

Ultra-high-strength Materials (UHSS) can be used to build modern skyscrapers. They enable lighter and thinner components without structural failure. In comparison with older materials, recent studies show a 20–30% decrease in the weight of the entire structure, which reduces cost and the impact on nature.

- Next-Generation Automotive Design

Car manufacturers utilize UHSS to make durable yet lightweight car frames. This shift could improve fuel efficiency and emissions by 10% while increasing safety during accidents, as a significant impact would be absorbed.

- Polar Wind Turbines

Due to the advancement of renewable energy technologies, UHSS is becoming more important in the production of wind turbine parts. Its capacity to withstand high fatigue wind loads guarantees that the turbines will be more effective and last longer. Turbines based on UHSS are expected to increase energy production by twenty percent while lowering maintenance requirements.

- Construction Of Bridges

Building bridges with longer spans is a common feature in modern civil engineering. The use of UHSS eliminates the need for excessive materials, which results in reduced construction costs, lower carbon emissions, and eco-friendliness. UHSS beams and cables have superior load-bearing capabilities, which enhance their durability against numerous environmental forces like earthquakes and heavy traffic.

These characteristics maximize the unrivaled potential UHSS holds in engineering and designing modern infrastructures. Continued development will shape the future of diverse industries using these materials.

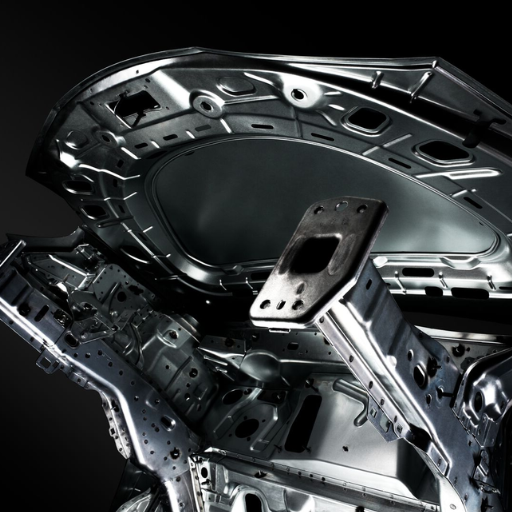

How is Ultra-High Strength Steel Manufactured?

UHSS is produced by sophisticated alloying and exact thermal treatment. First, carbon, manganese, and silicon are used as the steel’s reinforcing and toughening alloying ingredients. Then, the steel’s microstructure is refined by strengthening, Quenching, and Tempering controlled heating and cooling cycles. Innovative approaches, such as thermo-mechanical rolling, are used to reshape modern manufacturing’s UHSS material standards. This systematic method with controlled attention guarantees the best superiority of Uof HSS, designed for ultra-demanding work.

The Role of Martensitic and Dual Phase Processes

| Parameter | Martensitic Process | Dual-Phase Process |

|---|---|---|

| Formation | Rapid quenching of austenite | Controlled cooling from austenite |

| Microstructure | Body-centered tetragonal | Ferrite matrix with martensite islands |

| Strength | Very high, up to 700 Brinell | High, depends on martensite fraction |

| Ductility | Low, brittle without tempering | High, due to ferrite phase |

| Applications | Tools, wear-resistant parts | Automotive, crash-resistant components |

| Key Features | High hardness, low ductility | Balance of strength and formability |

| Heat Treatment | Requires tempering to reduce brittleness | Intercritical annealing for phase control |

| Cost | Higher due to quenching requirements | Moderate, suitable for mass production |

| Weldability | Challenging, requires special techniques | Good, suitable for automotive assembly |

| Energy Absorption | Limited | Excellent, ideal for crash safety |

Welding Techniques for UHSS Products

| Technique | Key Features |

|---|---|

| Resistance Spot Welding | Low distortion, high cost-effectiveness |

| Laser Welding | High speed, low heat input, precise joints |

| Gas Metal Arc Welding | Common, high heat input, versatile |

| MIG Brazing | Low heat input, reduced deformation |

| TIG Welding | Precise, suitable for thin materials |

| Submerged Arc Welding | High efficiency, limited to thick sections |

| Preheating | Prevents cracking in thicker materials |

| Post-Weld Heat Treatment | Restores strength, reduces brittleness |

| Electrode Selection | Low-hydrogen electrodes for SMAW |

| Weld Quality Control | Avoid porosity, ensure complete root fusion |

Challenges in Advanced Steel Production

Producing advanced steel such as ultra-high-strength steel (UHSS) comes with unique challenges that demand careful attention to detail and innovative solutions. Below are five key challenges faced during advanced steel production:

- Maintaining Consistent Quality Control

Ensuring uniform microstructural properties across batches is a significant hurdle. Variations in temperature, composition, or manufacturing techniques can lead to inconsistencies in strength and ductility.

- Mitigating Hydrogen Embrittlement

Advanced steels are highly susceptible to hydrogen-induced cracking. Hydrogen during production or use can compromise the material’s structural integrity and lead to premature failures.

- Achieving Precise Alloy Composition

Advanced steels often require complex compositions, including precise amounts of carbon, manganese, or chromium. Managing the ratios of these elements and minimizing impurities like sulfur or phosphorus is critical to performance outcomes.

- Overcoming Welding Challenges

UHSS materials require specialized welding techniques to prevent defects such as cracking and maintain their mechanical properties. High-strength steels are prone to heat-affected zone (HAZ) issues during welding.

- Balancing Strength with Formability

While advanced steels must exhibit exceptional strength, they also need sufficient ductility for shaping in automotive and industrial applications. Striking this balance remains a technical challenge during production.

Each of these challenges highlights the need for ongoing research, technological advancements, and precise process management to push the limits of steel performance while ensuring sustainable production methods.

References

- Hydrogen Dependent Material Properties of UHSS for Aerospace Applications – A detailed study on UHSS properties in aerospace applications.

- Mechanical Properties of Ultra-High Strength (Grade 1200) Steel Tubes – Research from Monash University on UHSS mechanical properties.

- Hydrogen Assisted Cracking of Ultra-High Strength Steels – A study from the University of Virginia on hydrogen effects in UHSS.

Frequently Asked Questions (FAQ)

Q: What is ultra-high-strength steel, and why is it important?

A: Ultra-high-strength steel is a product category that exhibits superior strength and unique mechanical properties. These steels have a yield strength of at least 550 MPa and are crucial for applications requiring enhanced durability and reduced weight, such as in the automotive and aerospace industries.

Q: How does ultra-high-strength steel differ from traditional steel products?

A: Ultra-high-strength steel differs from traditional steel products because it offers higher strength and elongation capabilities. These steels, including advanced high-strength steels (AHSS), are designed to provide a tensile strength of at least 780 MPa, making them suitable for demanding applications that require both strength and plasticity.

Q: What are some defining steels in advanced high-strength steel products?

A: Some defining steels in advanced high-strength steel products include dual-phase (DP), complex phase (CP), and press hardening steel (PHS). Each has unique characteristics that provide various combinations of strength, ductility, and toughness.

Q: What is the role of yield strength and tensile strength in ultra-high-strength steel?

A: Yield and tensile strength are critical in ultra-high-strength steel as they determine its ability to withstand deformation and ultimate fracture. These properties ensure the steel can support significant loads without compromising its structural integrity.

Q: Can you explain the significance of the 3rd gen steels?

A: The 3rd gen steels represent the latest advancements in AHSS, offering a balance of superior strength and ductility. They are designed to meet the increasing demands for safety and efficiency in industries such as automotive manufacturing, providing enhanced properties over previous generations.

Q: What applications benefit the most from advanced and ultra-high-strength steels?

A: Advanced and ultra-high-strength steels benefit automotive body structures, aerospace components, and construction materials the most. These applications require materials with high yield and tensile strengths and the ability to absorb energy during impacts.

Q: What are some challenges associated with using ultra high-strength steel products?

A: Some challenges include the difficulty in forming and welding due to their superior strength. Additionally, precise processing techniques are required to harness their full potential, often necessitating specialized equipment and expertise.

Q: How do high-strength low-alloy (HSLA) steels compare to ultra-high-strength steels?

A: High-strength low alloy (HSLA) steels are designed to provide good strength and toughness at lower weight, but they generally have lower strength compared to ultra-high-strength steels. HSLA steels are used in applications where weight savings are important but do not require the extreme strength offered by ultra-high-strength variants.

Q: What are AHSS application guidelines?

A: AHSS application guidelines involve considerations for processing, forming, and joining methods to optimize the performance of these steels. They also include understanding the unique mechanical properties of AHSS and implementing practices that ensure structural integrity and cost-effectiveness in production.

Q: What is the significance of a minimum tensile strength in defining ultra-high-strength steels?

A: Minimum tensile strength is crucial for defining ultra-high-strength steels, as it ensures the material can withstand significant stress before breaking. This characteristic is essential for applications that demand maximum strength and safety, such as crash-resistant automotive components.