Stainless steel is a crucial material that finds applications in numerous industries because of its remarkable characteristics, like resistance to corrosion, durability, and versatility. Like all other universally accepted materials, stainless steel comes in many grades, directly impacting its performance and the range of applications. This guide will delve into the different grades of stainless steel based on its composition, mechanical properties, and functionality. This blog post will help readers understand how these classifications impact functionality, from austenitic and ferritic to martensitic and duplex grades. For anyone engaged in manufacturing or engineering or even selecting materials, this article will assist in understanding the different grades of stainless steel, enabling you to make the correct choices.

What are the Types of Stainless Steel?

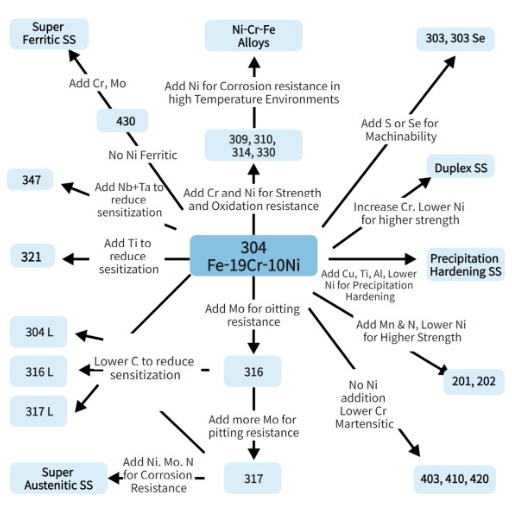

Stainless Steel is generally classified into four primary categories based on microstructure and alloy composition:

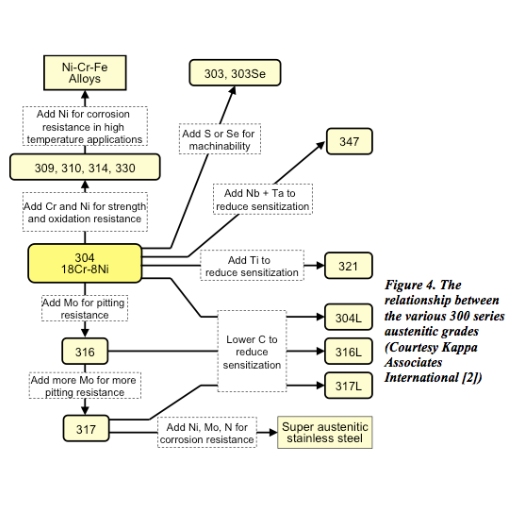

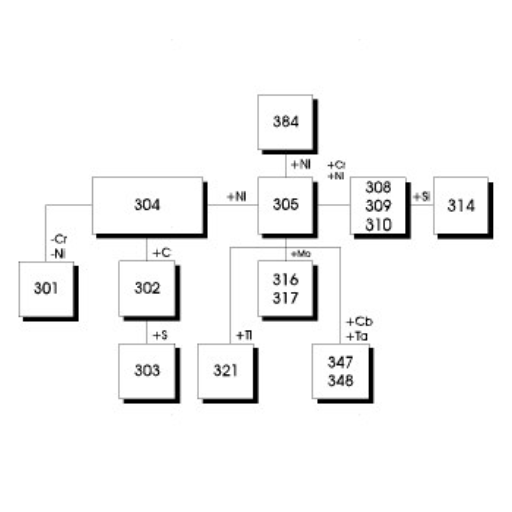

- Austenitic Stainless Steel—Non-magnetic with high levels of chromium and nickel, austenitic stainless steel is the most abundant type of stainless steel. It has excellent corrosion resistance and formability/weldability. 304 and 316 are the standard grades of this type.

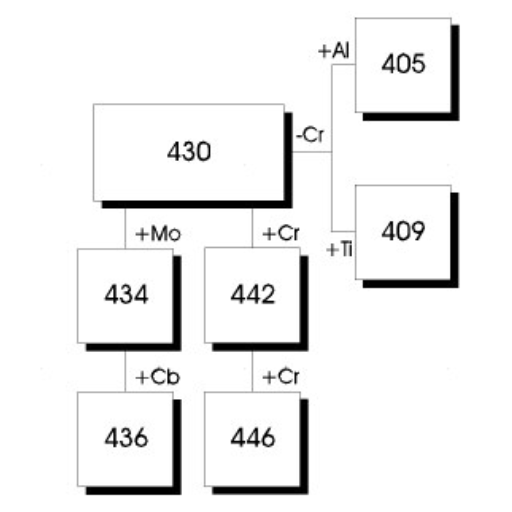

- Ferritic Stainless Steel—Compared to their austenitic counterparts, ferritic steels are lower in nickel content and corrosion resistance. However, they make up for it in their good thermal strength. Ferritic steels are also magnetic, a trait not found among austenitic grades. Grade 430 is one of the most widely used ferritic stainless steel.

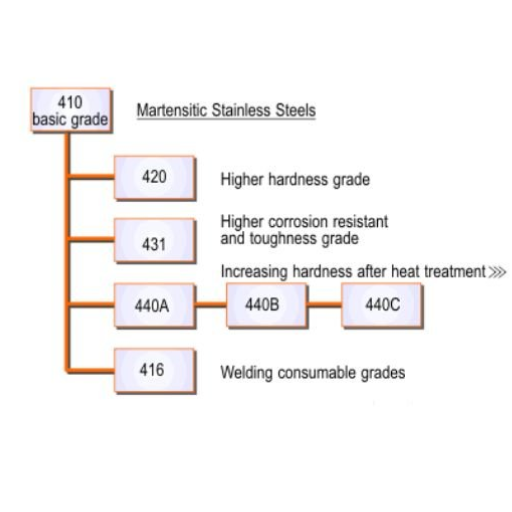

- Martensitic Stainless Steel—While less resistant than austenitic and ferritic grades, this particular grade is known for its strength and hardness. It is used in applications requiring tempered and hardened materials like utensils. A commonly known example of this grade is 410.

- Duplex Stainless Steel – The mixture of austenitic and ferritic structures gives this type superior strength and resistance to stress corrosion cracking. It also makes it widely popular in demanding industrial environments. 2205 and 2507 grades are some common examples.

Selecting the appropriate type of stainless steel depends on the degree of corrosion resistance needed, mechanical strength, cost efficiency, and operating conditions.

Overview of Austenitic Stainless Steel

Known for resisting rust, high flexibility, and being non-magnetic, Austenitic stainless steel is the most commonly used type. This type contains chromium and nickel; some well-known grades include 304 and 316. Austenitic stainless steel is easier to weld and put in various shapes, therefore it is used in many industries, like food and chemical processing, and construction. Another great feature of this type of steel is that it can withstand very low and very high temperatures, making it useful for extreme cryogenic and high-temperature applications.

Characteristics of Ferritic Stainless Steel

As the name suggests, Ferritic stainless steel is primarily made from iron and chromium, with the latter being 10.5 to 30 percent. Ferritic stainless steel possesses a body-centered cubic (BCC) crystal structure, which is beneficial for its ability to resist corrosion in oxidizing and mildly corrosive environments. Unlike Austenitic stainless steel, Ferritic stainless steel is magnetic, and because it has lower nickel content, it is cheaper for those businesses that require it.

Stress corrosion cracking resistance and oxidation resistance up to 750 °C are two primary characteristics of ferritic stainless steel. The grade determines the exact temperature value. This group contains 409, 430, and 441 grades constructed for use in automotive exhaust systems, appliances, and heat exchangers.

Compared to austenitic stainless steel, ferritic stainless is less ductile, more thermally conductive, and less able to be welded. Though having limited weldability because of ductility reduction and grain growth in the heat-affected zones, ferritic stainless steel demonstrates superb formability in thinner gauges, making it ideal for structural components needing enhanced strength and thermtown conductivity.

Exploring Martensitic Stainless Steel

The carbon content in ferritic steel grade is significantly lower than in martensitic steel, allowing it to undergo martensitic transformation. This is what provides the developed strength and hardness after heat treatment. Usage examples include knives. Turbine blades and surgical instruments, where wear resistance is crucial. Though this type of steel offers various advantages, compared to ferritic or austenitic grades, it has the weakest corrosion resistance and is the most brittle when manipulated.

Understanding Duplex Stainless Steel

Duplex stainless steel is a better version of ferritic stainless steel & austenitic stainless steel. It has better strength along with an improved ability to withstand stress corrosion cracking. Duplex steel has a balanced chromium, nickel, molybdenum, and nitrogen composition. Nitrogen increases the mechanical strength and improves the corrosion resistance of duplex stainless steel. Compared to austenitic grades, duplex stainless steel has a much higher yield strength and more excellent resistance to stress corrosion caused by chlorides. Fabrication and welding of duplex stainless steel demands extreme care to conserve its prerogatives.

How to Identify Stainless Steel Grades?

While trying to identify the grade of stainless steel belonging to duplex, well-known properties such as the exact magnetic response, the chemical make-up, and the mechanical parameters that describe the material need assessing. An example would be austenitic 304 and 316, which had a high amount of chromium and nickel, making them non-magnetic and highly corrosion-resistant. Grade 430 ferritic is less corrosion-resistant, which explains its lower dollar price. The stronger they are, the more partial magnetic response they have. Spectroscopy and X-ray fluorescence (XRF) analysis methods give precise results on the composition, making identification of a grade straightforward. Moreover, corrosion surface testing with hardness measurements can serve as additional proof.

Key Properties of 304 Stainless Steel

304 stainless steel is critically acclaimed for its balance of properties. Due to the high concentration of chromium and nickel, it presents excellent corrosion resistance in different environments. Similar to other grades, it also has good formability and weldability. In addition to this, it provides high tensile strength and maintains moderate to high durability under elevated temperatures, making it reliable for structural and industrial applications. Unlike other alloys, its non-magnetic nature in the annealed state makes it stand out even more.

Differences and Similarities: 304 and 316

Both 304 and 316 stainless steels are very similar in some aspects; they are resistant to corrosion, durable, and can be used for varying purposes. The primary differentiating factor is the chemical composition of the two. Unlike 304, 316 contains molybdenum, enabling it to resist pitting and crevice corrosion, especially in chloride-dominated places such as chemical or marine environments. This makes 316 an ideal candidate for harsher conditions, while 304 is more economical and works well for general-purpose applications. They both remain non-magnetic in annealed states and are easily welded and formed. However, due to its added corrosion resistance, using 316 is more desirable in specialized applications.

What Makes 409 Stainless Steel Unique?

As analyzed, 409 stainless steel is uniquely positioned to provide thermal conductivity, oxidation resistance, and weldability at a cost-effective price. As ferritic stainless steel, it has a lower chromium content than 304 and 316, making it more affordable while serving less aggressive environments. Its primary application is in automotive exhaust systems due to its economical resistance to oxidation and high temperatures. Indeed, 409 stainless steel is more cost-efficient and performance-optimal when compared to higher-grade stainless steel.

Why are There 4 Types of Stainless Steel?

There are four types of stainless steel: duplex, martensitic, ferritic, and austenitic, which accommodate different industrial and environmental needs. Each stainless steel type has a specific microstructure that affects mechanical properties, performance, corrosion resistance, and overall efficiency. For instance, austenitic stainless steels are highly used because of their superior resistance to corrosion and excellent formability, ferritic is more widely known for being cost-effective with moderate corrosion resistance, and martensitic grades stand out for their strength and hardness. On the other hand, duplex stainless steels have the best combination of austenitic and ferritic grades, which offers high strength and excellent resistance to stress corrosion. This classification allows engineers, manufacturers, and industries to rely on those alloys for their specific purposes, guaranteeing high levels of efficiency.

Role of Chromium and Nickel in Each Type

Stainless steels possess critical alloying elements such as chromium and nickel, affecting their properties and performance. While all steels require a certain content of chromium for corrosion protection, stainless steels especially need it because it can form a passive layer of chromium oxide. To be classified as stainless steel, alloys need to have an absolute minimum of 10.5% chromium content, with higher and more reliable grades like 316 and 304 having about 16-18%.

Unlike other metals, Nickel is necessary for maintaining an austenitic phase that provides overall enhanced formability, toughness, and weldability even in very low temperatures. For example, the austenitic grades 304 and 316 steel contain roughly 10% and 14% nickel, respectively, while 304 is better at corrosion resistance, especially in chlorides- and acids-containing environments. Even more, the duplex stainless steels have lower levels of nickel (between 3%-6%), making them more cost-efficient in their mechanical properties of strength and corrosion resistance. While giving Martensitic and ferritic stainless steels less than 1%, nickel helps them depend on chromium to achieve the required specifications; lower nickel content still helps create tougher alloys.

All types of stainless steels need a combination of chromium and nickel to precisely balance the technical requirements for all possible applications, like corrosion resistance, thermal stability, and mechanical strength in diverse environmental and industrial settings.

Impact of Corrosion Resistance on Applications

The choice of materials for crucial uses in construction, chemicals, and even in the marine environment is affected by the degree of corrosion resistance any material has. In my area of expertise, duplex and austenitic stainless steels provide the highest corrosion resistance. This property guarantees durability, minimizes maintenance costs, and prevents structural deterioration that poses safety risks. For example, in a chemical plant, using corrosion-resistant alloys helps prevent contamination and protects the vessels and piping systems from corrosion. This is a clear example of why material composition is critical in ensuring reliable operations in a facility.

What is the Difference Between 304 and Other Grades?

Type 304 stainless steel is an austenitic alloy distinguished by its high chromium (18%) and nickel (8%) proportions, which offer exceptional resistance to corrosion and good forming ability. Unlike 316-grade stainless steel, 304 does not have an addition of molybdenum, which is beneficial in providing further resistance against chlorides and other aggressive chemicals, making 316 better for marine use or highly corrosive conditions. In contrast, 304 offers superior corrosion resistance and durability compared to the 200 series stainless steel due to its nickel composition. Moreover, 304 is economically efficient for general use, while better performance 316 or duplex steels are suited for harsher environments.

Comparing Grade 304 with Grade 316

Comparison of 304 and 316 Stainless Steel Grades As with any variation of stainless steel, Grade 304 and Grade 316 differ in chemical composition. Both grades are austenitic with high chromium and nickel content, while Grade 316 is enhanced with an additional 2-3% molybdenum. This additional chemical component makes Grade 316 stainless steel alloys more resistant to pitting and creepy corrosion in molybdenum-rich environments.

Chemical Composition Comparison (Approximate Values):

- Grade 304:

- Chromium (18-20%)

- Nickel (8-10.5%)

- Molybdenum (0%)

- Grade 316:

- Chromium (16-18%)

- Nickel (10-14%)

- Molybdenum (2-3%)

Performance Characteristics

- Corrosion Resistance: Grade 316 stainless steel alloys tend to outperform Grade 304 when submerged in salt water and located in coastal regions. This is also the case when exposed to deicing chemicals, as molybdenum is more prevalent in Grade 316.

- Temperature Resistance: 316 may provide superior oxidation resistance, but both grades have similar tolerances.

- Strength and Durability: Both grades demonstrate similar tensile and yield strength at room temperature.

- Cost: Due to Grade 316’s superior elemental composition, it does typically exceed 304’s cost.

Applications

- Grade 304 is preferred for indoor kitchen appliances, sinks, and architectural designs for domestic and general purposes.

- For marine environments or industries with chemicals, pharmaceuticals, or medicinal processing, Grade 316 can withstand more corrosive environments.

When choosing between these two grades, it is important to understand the intended application’s operational and environmental requirements.

Advantages of Grade 304 in Various Industries

- Cost-effectiveness: Grade 304 is economically superior to Grade 316 due to its lower price, strong corrosion resistance, and durability, making it financially attractive in many fields.

- Versatility: This grade is suitable for a wide range of applications, including food processing, brewing, and household appliances, due to its resistance to acids and ease of fabrication.

- Ease of maintenance: Its stain resistance and smooth surface contribute to low maintenance care, providing significant benefits for healthcare and manufacturing industries where hygiene is paramount.

- Weldability and formability: Grade 304 is famous for being easily weldable and formable, allowing many goods to be produced quickly and efficiently.

Is 409 Stainless Steel a Cost-Effective Option?

Yes, the 409 grade of stainless steel is inexpensive and especially useful in applications that do not require severe corrosion resistance. It is widely used in the automotive industry for exhaust systems but also works as a structural support in other industries due to its good oxidation resistance and affordability. While the 409 grade does not offer the same level of corrosion resistance as higher grades such as 304 or 316, the low cost coupled with good performance in mild environments means it can serve specific needs economically.

Examining the Stainless Steel Grade 409

Looking at stainless steel grade 409, I consider it a highly economical material for applications that require durability while being low-cost. It provides adequate oxidation resistance, especially at temperatures up to 675 degrees celcius, making it useful for automobile exhaust systems. The grade does not match the corrosion resistance of higher grades like 304 or 316, but the chromium composition does allow for decent performance in harsher environments. The mechanical properties that stand out to me are its good weldability and reasonable strength, which make it bilaterally suitable for structural applications. All in all, 409 stainless steel is a good choice for industrial uses that require some corrosion resistance but are not essential.

Applications where 409 Stainless Steel Excels

409 stainless steel is best suited for areas that need great corrosion resistance, formability, and tolerance to high temperatures, all while being cost-effective. Because of its oxidation and thermal cycling resistance for up to 1300°F (704°C) is most widely used in the automotive industry in components such as catalytic converters, mufflers, and pipes. Furthermore, it is also used in agricultural machinery, heat exchangers, and structural parts for moderation corrosion resistance durability. With a chromium content usually at 10.5-11.75% alloying, 409 can provide corrosion resistance and is easy to weld and machineable. Its tensile strength commonly ranges between 380-485 MPa, making it suitable for structural integrity in demanding conditions.

References

- Stainless Steel Grades and Families: Explained – Unified Alloys

- Understanding Stainless-Steel Grades – Essentra Components

- Guide to Stainless Steel Grades – Kloeckner Metals

Frequently Asked Questions (FAQ)

Q: What is the significance of different grades of stainless steel?

A: Different grades of stainless steel are designed to provide specific properties such as corrosion resistance, strength, and durability. These grades are categorized based on the alloy composition and mechanical properties. The American Iron and Steel Institute classifies these into series such as 300, 400, etc., to help identify their specific characteristics.

Q: How does 304 stainless steel compare to 316 stainless steel?

A: 304 stainless steel contains chromium and 8% nickel, making it a versatile and widely used austenitic steel. In contrast, 316 stainless steel includes additional molybdenum, which enhances its corrosion resistance, especially in marine environments. This makes 316 stainless steel the preferred choice for applications exposed to saltwater or other harsh conditions.

Q: What makes 316 stainless steel a marine-grade option?

A: 316 stainless steel is considered marine grade because it is highly resistant to chloride corrosion, which is common in marine environments. The presence of molybdenum in its composition provides enhanced protection against rust and pitting, making it ideal for use in saltwater and coastal applications.

Q: Why is 440 stainless steel known for its high hardness?

A: 440 stainless steel, particularly 440C, is known for its high hardness due to its high carbon content. This grade is often used in applications requiring excellent wear resistance and edge retention, such as cutlery and tools. It can be further hardened through heat treatment processes.

Q: What is the difference between 410 stainless steel and grade 420 stainless steel?

A: Grade 410 stainless steel is a basic martensitic steel with good hardness and corrosion resistance. It is often used in cutlery and kitchen utensils. Grade 420 stainless steel has a higher carbon content, which allows it to achieve greater hardness through heat treatment. This makes it suitable for surgical instruments and other applications requiring a sharp edge.

Q: How does cold working affect the properties of stainless steel?

A: Cold working involves deforming stainless steel at room temperature, which increases its strength and hardness without the need for heat treatment. This process can improve the mechanical properties of austenitic steels like 301 and 302 stainless steel, making them more suitable for various industrial applications.

Q: Why is 304 stainless steel often used in food processing equipment?

A: 304 stainless steel is commonly used in food processing equipment due to its excellent corrosion resistance, hygienic properties, and ease of cleaning. Its composition, which includes chromium and 8% nickel, makes it an ideal choice for environments where sanitation is crucial.

Q: What characteristics make 430 stainless steel a popular choice?

A: 430 stainless steel is a ferritic alloy known for its good corrosion resistance and formability. It is often used in applications like automotive trim and appliances, where its aesthetic and functional properties are valued. Due to its lower nickel content, it is less expensive than austenitic grades.

Q: Which is the best grade stainless steel for high-temperature applications?

A: For high-temperature applications, 321 stainless steel and 347 stainless steel are excellent choices. These grades contain titanium and niobium, which help stabilize the alloy and prevent carbide precipitation, maintaining strength and corrosion resistance at elevated temperatures.