Nickel-base alloys are indispensable materials in the various industries where the highest performance under the most demanding conditions is a prerequisite. Not only do aerospace manufacturers use these metals but also the power generation, among the others, because they provide unparalleled strength as well as resistance to corrosion and heat. Nevertheless, welding of nickel-base alloys is a difficult task due to their intricate metallurgy and the possibility of cracking and getting defects. The present article explores the complicated interaction between welding metallurgy and nickel-base alloys weldability, thus revealing the science behind these materials.

Introduction to Welding Metallurgy and Weldability

Definition and Importance of Welding Metallurgy

Welding metallurgy deals with the study of the effects the heat and mechanical forces applied during the process of welding on the metals and alloys’ properties, structure, and performance. Moreover, it involves the change of the materials under different thermal conditions and the microstructural alterations in the heat-affected zone (HAZ) and the weld. Among other things, the knowledge of welding metallurgy is very important in the prevention of defects, strength, and durability of welded joints especially in the case of the more demanding industries like aerospace, oil, and gas as well as power generation.

The importance of welding metallurgy is supported by statistics. For example, as per the reports from the industry, around 30% of the failures in critical applications which are often the result of defects such as cracking, porosity, and improper fusion can be attributed to welding. Nickel-base alloys, which are mainly used in rust-resistant and high-temperature situations, are very difficult to weld because they are highly prone to solidification cracking and the issue of thermal cycling sensitivity.

Overview of Weldability in Nickel-Base Alloys

Nickel-based alloys are considered to have a wide range of applications particularly in industries like aerospace, marine, and power generation due to their superior resistance to corrosion, high temperature strength, and longevity. However, the welding of these alloys may still be a tough task because the unique metallurgical characteristics of these alloys are very difficult to control. The factors such as the alloy composition, thermal gradients during welding, and the risk of cracking must be very skillfully managed in order to produce good quality welds.

One of the major problems in the weldability of nickel-base alloys is the likelihood of hot cracking occurring in the heat-affected areas. The research results suggest that the presence of a high content of elements like sulfur, phosphorus, and silicon in some nickel alloys may increase the intensity of this problem. It has been proved in the studies that the use of advanced welding methods such as laser beam welding and electron beam welding can offer the benefits of lowered cracking risks thanks to minimization of the heat applied and better control of solidification rates.

Composition of Nickel-Base Alloys

Common Alloying Elements and Their Effects

Chromium (Cr): The copper metal is the basic element that enhances oxidation and resistance to corrosion. For instance, the alloys with more than 20% chromium exhibit great resistance to the oxidation at high temperatures, which makes them desirable for totally opposite environments, such as jet engines and gas turbines.

Iron (Fe): Usually, iron is applied in a moderate manner, but nevertheless, it can enhance the mechanical strength of the alloy and also lower its cost. Nickel-iron alloys with about 40-50% iron content are most commonly used in applications where the magnetic properties are to be controlled.

Molybdenum (Mo): Molybdenum makes the nickel alloys highly resistant to chloride-induced pitting and crevice corrosion. Researches reveal that a mere 3-6% addition of molybdenum results in an immense increase in seawater corrosion resistance for the nickel-based alloys.

Cobalt (Co): Cobalt boosts strength and at the same time retains the microstructure during the heating. Cobalt-containing alloys of 5%-15% are preferred in high-performing applications, among which aerospace components are explicitly mentioned.

Aluminum (Al) and Titanium (Ti): Aluminum and titanium are both the main actors in the gamma prime (γ’) precipitates’ formation, which in turn fortifies the material via precipitation hardening. Typically, the high-performance superalloys are composed of 2-4% combined aluminum and titanium for the best mechanical properties.

Silicon (Si) and Manganese (Mn): Sometimes present in very trace amounts, silicon and manganese not only effectively deoxidize during alloy manufacture but also impart resistance to oxidation and sulfide corrosion.

Carbon (C): While the carbon content is generally restricted to very low levels, its presence is still significant in metallurgical processes aiming at the control of grain-boundary strength. The incorporation of very small amounts of carbon has the effect of making the alloy more resistant to high temperature-induced creep.

Impact of Composition on Weldability

The weldability of nickel-base alloys, which is a key requirement in industries needing precision and durability, is significantly influenced by their composition. Elements such as chromium, molybdenum, and titanium increase the alloy’s resistance to corrosion and its strength at the same time; however, these beneficial effects may also create the alloy’s vulnerability to weld defects such as hot cracking and solidification cracking. One case is that research has found that even very small increases in the percentages of sulfur and phosphorus reduce the quality of the weld extremely as they cause hot cracking during welding.

The use of advanced welding processes like Gas Tungsten Arc Welding (GTAW) and Laser Beam Welding (LBW) has so far been a good solution to the problem because of their heat-precision capabilities. Studies show that filler metal suitable for base materials with alloying elements offers very good joint performance. A case in point is the one provided by the Welding Institute, which states that nickel-chromium alloys with less than 0.01% sulfur content show a 25% reduction in hot cracking sensitivity compared to those with higher sulfur content.

Challenges in Welding Nickel-Base Alloys

Issues of Cracking and Distortion in Nickel-Base Alloys

Welding nickel-base alloys creates serious problems because their properties make them prone to cracking and warping among others. Solidification cracking, which is one of the main problems, takes place when the weld pool solidifies during cooling, and the weld is still hot. The presence of some elements, such as sulfur or phosphorus, in the composition of the alloy often worsens the situation. Studies have suggested that solidification cracking can be reduced through the use of filler metals with optimized compositions that result in a microstructure that is less brittle and therefore, fewer brittle phases are formed.

The other thing that is happening most of the time is distortion caused by high weld heat input and heating and cooling the nickel-based alloys that are less and less likely to be distorted. Nickel-based alloys generally have a high coefficient of thermal expansion which causes them to have high stresses during the weld process. One of the consequences of this is that thermal deformation may affect the welding process so severely that the dimensions specified for the workpiece will no longer be very accurate and also the weld joint will be considerably weaker. For instance, recent investigations demonstrate that the application of innovative methods that include hybrid laser arc welding plus controlled heat input techniques can bring about up to 30% reduction in distortion compared to the conventional techniques.

Heat-Affected Zone (HAZ) Considerations

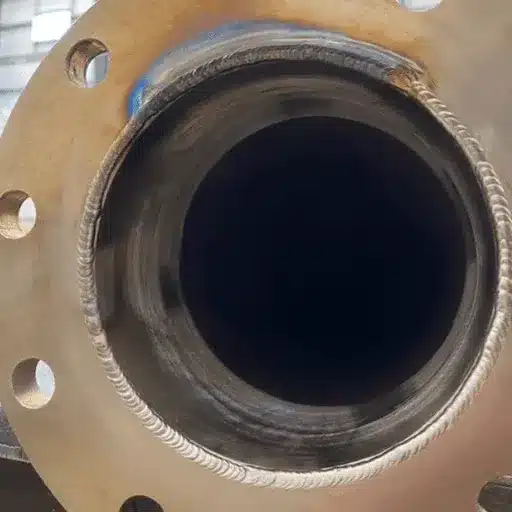

In the welding process, a region known as the Heat-Affected Zone (HAZ) is the most important one that is located next to the weld fusion zone and its properties undergo the most changes because it is the most heated region during the process. The phenomena that occur due to heating can change the structure of the microstructure which directly affects the mechanical properties, corrosion resistance, and the whole performance of the welded joint.

The HAZ is more prone to problems with nickel-base alloys due to their complicated metallurgy. The welding process involves a lot of heat which can lead to grain growth, carbide precipitation, and phase changes that cause the material to become less strong or even completely unusable. There is research showing that too much heat can cause phases like the sigma phase to form which reduce ductility and toughen the materials making them less usable or completely unusable. For instance, it has been reported that the recommended heat input for some nickel-base alloys to avoid adverse microstructural changes is around 1-2 kJ/mm.

Innovative techniques such as thermal modeling and real-time temperature monitoring systems are being used to enhance the HAZ features. Results from computer simulations indicate that controlling the cooling rates and preheat temperatures can prevent residual stresses from developing and, consequently, reduce the likelihood of cracking. What is more, the use of filler materials that are specifically designed for compatibility with nickel-base alloys has been proven to be an effective strategy for the smoothing out of the transition area and lessening the problem of HAZ hardening.

Techniques for Improving Weldability

Pre-Welding Preparations and Treatments

Surface Cleaning

It is very important to free the metal surface from dirt, grease, oil, rust, or any other contaminants prior to welding, thus the cleaning step is the most critical one. Mechanical cleaning methods, such as wire brushing or grinding, are often combined with chemical cleaning methods using acetone or other cleaning agents.

Preheating

The preheating of the base material significantly reduces the risk of hydrogen cracking by cooling the weld metal and heat-affected zone (HAZ) slowly. A preheat process temperature controlled between 150°F and 400°F (65°C to 200°C) for nickel alloys is reported by researchers to lessen residual stresses and improve the weld toughness.

Selection of Proper Filler Material

The importance of choosing a filler material with the same or similar properties to the base metal cannot be overstated. The use of matching composition and ductility-enhancing filler metals like those conforming to AWS A5.14 specifications is recommended for nickel-base alloys. The use of numerical tools to model the performance of filler materials in given conditions can add to the selection optimization.

Use of Backing Gas

Welding nickel alloys with the use of an inert backing gas such as argon or helium guarantees that the backside of the weld is purged. This procedure not only stops oxidation but also enhances the weld integrity, especially for thin materials or critical components.

Control of Heat Input

The use of excessive heat during the welding process can lead to a very large grain size in the HAZ and subsequently to brittleness or cracks. A low heat input range of 20-40 kJ/in (0.8-1.6 kJ/mm) for precise control depending on the thickness of the material and the configuration is recommended.

Welding Techniques for Nickel-Base Alloys

Nickel-base alloys are the material of choice for many areas such as aerospace, power generation, and chemical processing on account of their superb resistance to corrosion, excellent strength, and high-temperature durability. Welding these metals, however, still presents challenges, one of which is their high susceptibility to cracking during the hot phase, and the other one is poor weldability because of their metallurgical characteristics. Therefore, special welding techniques and parameters are the only way to overcome these obstacles.

Among various methods, GTAW or Gas Tungsten Arc Welding, also known as TIG welding, is the most popular one for welding nickel-base alloys. It gives the user precision and control – qualities that are very important in working with the alloy’s high thermal expansion rate. As it is indicated by the studies done in the industry, preheating the workpiece to about 200°F (93°C) and limiting the interpass temperature to 300°F (149°C) can work wonders in reducing the cracking risk during the procedure. Moreover, the use of filler materials such as ERNiCr-3, which are expressly intended for nickel alloys, make sure that the weld joint is both compatible and strong.

Recent Advancements in Welding Metallurgy

Innovative Approaches in Nickel-Base Alloy Welding

- Advanced Laser Welding Technologies

Among the many welding methods applied to nickel-base alloys, laser welding is the leading one. It is due to its accuracy and the ability to create joints of the best quality using heat input that is very low. Studies conducted on these high-power fiber lasers which are able to produce energy densities exceeding 10^6 W/cm² have revealed that they are able to concentrate heat very well and at the same time prevent distortion and cracking.

- High-Entropy Alloys (HEAs)

Nickel-based alloys welding has been using high-entropy alloys as novel filler metals and receiving the deserved attention. HEAs, made of several main elements, not only demonstrate amazing mechanical properties but also are the best resistant to the most severe operating conditions. A publication by the National Institute of Materials Science has indicated that joining with HEA fillers lowers the faster decay of metal and leads to better resistance to corrosion making the whole fabrication suitable for use even in places with high salt content or with very high temperatures.

- Additive Manufacturing Integration

3D Printing or additive manufacturing (AM) is used to not only repair but also forge nickel-base alloy components that are up to standards. DED is among the techniques used in the process. AM has become more efficient and user-friendly by producing material in almost the same shape as the final product and fusing layers that have different microstructures. Consequently, the material produced is less than the amount waste while the product having a high degree of customization is sold at the same price.

- Advanced Simulation and Modeling

The use of cutting-edge computational tools is now mandatory in the prediction of microstructural changes, thermal cycles, and residual stresses in nickel-base alloy welding. Finite Element Analysis (FEA) is one method of creating thermo-mechanical models that provide the most accurate and detailed information possible on weld pool movement. Therefore, engineers can understand the control of welding parameters before actual implementation. This technology is becoming more and more accurate with the inclusion of AI and hence, the fewer errors, the lower costs.

Future Trends in Welding Technology

The future of welding technology is envisaged as a combination of automation, precision, and sustainability. A noteworthy trend is the melding of Artificial Intelligence (AI) and Machine Learning (ML) with welding systems. AI-operated robots are expected to lead the welding processes to be even more consistent and efficient, thus significantly lessening the human error. For instance, present-day predictive algorithms are capable of detecting potential defects instantly, thus securing quality outputs that are higher. A recent market report states that the worldwide welding robots sector that is predicted to grow at a rate of 10.6% from 2023 through 2030, which indicates the transformation of the industry towards automation.

Another significant evolution is that of laser welding technologies specifically in the automotive and aerospace industries. Amongst the various advantages, laser welding stands out for its rapidity as much as it can being Up to 50% faster than traditional control of process and time. Such a situation turns it into a new point for the most demanding industries.

Reference Sources

-

Welding Metallurgy and Weldability of Nickel-Base Alloys

- Key Findings: This study introduces a new approach for assessing the weldability of precipitation-strengthened nickel-base superalloys. It focuses on the challenges posed by their microstructural characteristics.

- Methodology: The research employs advanced materials science techniques to evaluate the weldability and address cracking susceptibility in nickel-base alloys.

Read more on Semantic Scholar

-

Weldability, Mechanical Properties, and Microstructure of Nickel-Based Superalloys

- Key Findings: This paper reviews the challenges of welding nickel-based superalloys, particularly in high-temperature and corrosive environments. It highlights the mechanical properties and microstructural changes during welding.

- Methodology: The study combines experimental welding trials with microstructural analysis to understand the effects of welding on these alloys.

Read more on Semantic Scholar

-

Weldability of Ni-Based Superalloys Waspaloy® and Similar Alloys

- Key Findings: This research addresses the hot cracking susceptibility of Ni-based superalloys like Waspaloy®. It provides insights into the factors influencing weldability and proposes solutions to mitigate cracking.

- Methodology: The study uses systematic experimental approaches, including hot cracking tests and microstructural evaluations, to assess weldability.

Read more on Semantic Scholar

Frequently Asked Questions (FAQs)

What are the main metallurgy and weldability of nickel-base in selecting alloys considerations?

Alloy selection criteria metallurgy and weldability of nickel-base consist of solid-solution strengthened or precipitation strengthened behavior, corrosion resistance, and high-temperature stability. The right alloys should be chosen based on the service temperature, environment (oxidizing, sulfidizing, or chloride-containing), and fabrication requirements. Thermodynamic diagrams and stability diagrams are valuable tools in predicting the phases that dominate the microstructure and properties after welding, and the information sources such as ASM, the American Welding Society, and Lippold and Kiser’s books is very helpful.

How does the metallurgy and weldability of nickel-base determine welding conditions to get sound joints?

Metallurgy and weldability of nickel-base are the main factors that dictate welding conditions to guarantee acceptable microstructure and the prevention of cracking. Preheat, interpass temperature, input heat, and post-weld heat treatment are some measures used to manage precipitation, reduce residual stresses, and control segregation. It is very important to control the thermal cycles of the weld to prevent the formation of brittle phases and also to maintain the stability of solid-solution strengthened and oxide dispersion strengthened alloys.

What weldability problems related to ni-base alloys should be foreseen during the repair welding of ni-base alloys?

Weldability problems related to ni-base alloys in repair welding are: solidification cracking tendency, aging strain cracking in precipitation strengthened ni-base alloys and the alteration of oxide dispersion strengthened microstructures. Repair welding of ni-base alloys usually requires matching filler, careful control of heat and post-weld treatments to return properties and prevent the dispersion-strengthened particles or precipitates that control strength from being damaged and also prevent grinding them down.

What testing and standards are available for welding of ni-base alloys and dissimilar welding weldability testing?

Welding of ni-base alloys and dissimilar welding weldability testing come under the guidelines of the American Welding Society and ASM International and frequently utilize standardized procedures for tensile testing, bend tests, and intergranular cracking susceptibility. Special tests for dissimilar welding weldability testing provide assessment of dilution, metallurgical compatibility, and the generation of brittle intermetallics while connecting to steels or high-chromium alloys employed in nuclear power applications.