Steel is one of the most versatile and widely used materials in the world, making it essential to understand the properties that define its performance in different applications. Among these properties, the melting point of steel plays a crucial role in determining its behavior under high-temperature conditions, influencing processes such as welding, forging, and heat treatment. This blog post will explore the melting points of various types of steel, including carbon steel, stainless steel, and alloy steel, and examine the factors that contribute to their differences. Additionally, we will discuss the significance of these melting points in industrial settings and practical applications, providing a comprehensive guide for professionals and enthusiasts alike. By the end of this article, you will have a clear understanding of how steel’s composition and processing impact its performance at elevated temperatures, empowering you with valuable insights for material selection and engineering decisions.

What is the typical melting point range for steel?

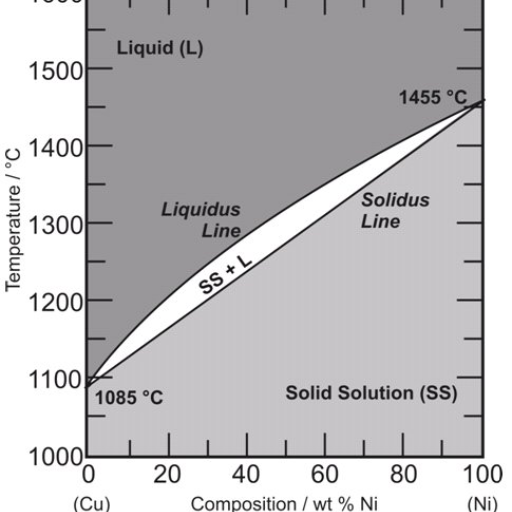

It is widely accepted that steel lofts begins to melt between 2,500 °F (1,370 °C) and 2,800 °F (1,540 °C). The estimate may change with respect to the alloying constituents due to the varying composition of the alloy constituents that always affects the solid and liquid temperature range of the steel. For example, the Carbon or Chromium coupled with Nickel can either increase or lower the melting point of the alloy. These Values are essential to be known during the execution of high temperature work like Forging, Casting or Welding.

How does carbon content affect steel’s melting point?

Carbon content has a significant impact on steel’s melting point. As carbon is added to steel, it forms iron-carbon alloys, which generally lower the melting temperature compared to pure iron. This is because the carbon atoms disrupt the iron’s crystal lattice structure, reducing the energy required for the material to transition from solid to liquid. For instance, low-carbon steel (with carbon content of up to 0.25%) typically has a higher melting point than high-carbon steel (with carbon content exceeding 0.5%). This variation is crucial in engineering and metallurgy, as it directly influences steel’s suitability for processes like casting, welding, or heat treatment.

What’s the difference between melting temperature and melting point?

Melting temperature and melting point are two interrelated but different concepts. Melting point refers to the physical condition of a specific temperature and standard atmospheric pressure where a crystalline solid becomes a liquid. A given substance always has a particular value that is termed its melting point. While melting temperature, however, refers to the broad range of temperature an alloy or a non-crystalline substance requires for it to become fully molten, marked by a more gradual, non-specific change, usually when dealing with practical scenarios. This difference makes a huge impact in Materials science and engineering, especially when dealing with alloys or impurities.

How do alloying elements influence steel’s melting point?

Adding other elements to steel’s constitution impacts its melting point considerably due to the changes in its composition and structure. Carbon, manganese, and chromium are known to decrease the melting point of steel because they weaken the crystal lattice structure, resulting in a more complex microstructure. Elements such as tungsten or molybdenum, with their high melting points and strong bonding characteristics, tend to increase the melting temperature. These changes become highly prominent when modifying the steel for specific applications, as these factors influence its performance at elevated temperatures, corrosion resistance, and overall strength. The relationship between alloying elements and impurities also aids in explaining the presence of a melting range as opposed to a definite melting temperature for a number of steel alloys.

How does the melting point of stainless steel compare to other steels?

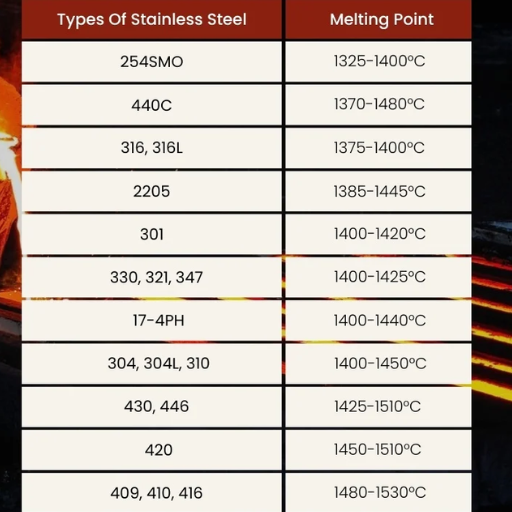

Because of its greater nickel and chromium content, stainless steel has a lower melting point than carbon steel and other alloy steels. On average, the melting point of stainless steel ranges from 2,500°F to 2,800°F (1,370°C to 1,540°C), whereas the melting point of carbon steel is significantly higher, generally around 2,700°F to 3,000°F (1,480°C to 1,650°C). The precise range for the melting point of stainless steel differs according to its composition, with some grades made specifically to withstand high temperatures and others for distinct industrial uses. These differences make stainless steel particularly versatile for environments requiring durability and heat resistance.

What factors determine stainless steel’s melting point?

Several key factors influence stainless steel’s melting point, including its chemical composition, the presence of alloying elements, and the material’s microstructure. Chromium, a primary component in stainless steel, enhances heat resistance but slightly lowers the melting range. Nickel and molybdenum, often added for corrosion resistance and strength, can further affect the melting temperature. Additionally, the grade of stainless steel—such as austenitic, ferritic, or martensitic—impacts thermal properties, with variations arising from their distinct crystalline structures and alloy ratios. Together, these factors determine the precise melting point and suitability of stainless steel for different applications.

Why does stainless steel have a higher melting point than carbon steel?

Stainless steel generally has a higher melting point than carbon steel due to its composition and alloying elements. While carbon steel is primarily made of iron and carbon, stainless steel contains significant amounts of chromium and other elements like nickel and molybdenum, depending on the grade. Chromium enhances corrosion resistance and increases the material’s heat tolerance by forming stable oxide layers. Additionally, the crystalline structure of stainless steel, especially in austenitic grades, distributes heat absorption differently, further raising its resistance to high temperatures. These factors make stainless steel capable of withstanding extreme heat, with melting points typically ranging between 2550°F and 2790°F, compared to carbon steel’s melting point of approximately 2500°F.

How does the type of stainless steel affect its melting point?

The type of stainless steel significantly affects its melting point due to variations in its chemical composition and microstructure. For instance, austenitic stainless steels, which include grades like 304 and 316, have melting points in the range of 2550°F to 2650°F, attributed to their high chromium and nickel content. Ferritic stainless steels generally have slightly lower melting points, ranging from 2500°F to 2550°F, due to their simpler composition and lack of nickel. Martensitic stainless steels, known for their high carbon content, also exhibit melting points around 2500°F. Variations in alloying elements, such as molybdenum or titanium, can further influence the melting range, making each type of stainless steel uniquely suited for specific high-temperature applications.

What are the melting points of different types of steel?

The melting points of different types of steel vary depending on their composition. Carbon steels generally melt within the range of 2600°F to 2800°F, while alloy steels have melting points influenced by their additional alloying elements, typically falling between 2500°F and 2700°F. Stainless steels, due to their mixture of chromium, nickel, and other metals, exhibit melting points around 2500°F to 2750°F, with specific types, such as austenitic and martensitic stainless steels, showing slight variations based on their unique compositions.

Which type of steel has the highest melting point?

The steel type with the highest melting point is tungsten steel for it contains tungsten as an alloying element, putting it alongside high-speed steels (Hss). With a melting point of around 6,192°F (3,422°C), tungsten greatly increases the heat resistance of the steel giving it much needed strength. Pure tungsten steel possesses amazing temperature properties and together with alloyed steels, carbon steel is regarded the best with a melting point range of 2,600°F to 2,800°F. However, the exact melting points of alloys such as stainless or tool steels is dependent on their precise composition.

What is the melting point of low-carbon steel?

The melting point of low-carbon steel typically ranges between 2,500°F and 2,700°F (1,370°C to 1,480°C). This variance depends on the precise composition of the steel, which mainly consists of iron with a small percentage of carbon (usually less than 0.25%). Low-carbon steel’s composition contributes to its relatively low melting point compared to high-carbon or alloyed steels, while still offering high ductility and versatility in applications like construction and manufacturing.

How does tool steel’s melting point compare to other steels?

Tool steel typically has a melting point slightly lower than that of regular carbon steels, ranging between 2,200°F and 2,500°F (1,204°C to 1,370°C). This melting range is influenced by the presence of additional alloying elements like tungsten, molybdenum, chromium, and vanadium, which enhance properties such as hardness, wear resistance, and toughness. These elements can lower the melting point compared to plain carbon steels but are necessary for the specialized performance required in cutting, shaping, and tooling applications.

How is the melting point of steel measured?

The melting point of steel is measured using precise high-temperature equipment, such as thermocouples in conjunction with a furnace or a differential scanning calorimeter (DSC). These devices monitor temperature as the steel is gradually heated, identifying the point at which it transitions from solid to liquid. Careful calibration and controlled environments are essential to ensure accurate readings, accounting for variations caused by the specific alloy composition.

What methods are used to determine the exact melting point of steel?

The exact melting point of steel is determined using several advanced methods. One common approach involves the use of thermocouples, which measure temperature changes within a controlled furnace environment as the steel is heated. Differential scanning calorimetry (DSC) is another key technique, which precisely tracks heat flow to detect phase transitions. Additionally, optical pyrometers are employed in high-temperature environments to measure radiated heat and pinpoint the melting temperature. These methods ensure accuracy by considering factors like alloy composition and environmental conditions.

How accurate are melting point measurements for steel?

The accuracy of melting point measurements for steel depends on the method and conditions used during the process. High-precision instruments such as thermocouples and DSC can measure melting points with an accuracy of ±0.5°C to ±2°C under controlled laboratory conditions. Factors like impurities, alloy composition, and environmental variables can slightly alter the measured values. While modern techniques significantly reduce errors, it is crucial to calibrate equipment properly and account for these factors to ensure reliable results.

What are the practical implications of steel’s melting point?

Steel’s melting point, typically around 1370°C to 1510°C depending on the alloy, has profound practical implications in various industries. It determines the temperature limits for processes such as welding, forging, and casting, ensuring structural stability and material performance under high heat. This property is crucial in sectors like construction, automotive, and aerospace, where steel components may be exposed to extreme temperatures. Understanding the melting point also aids in selecting appropriate alloys for specific applications, improving efficiency and safety in manufacturing and engineering projects.

How does knowing the melting point help in steel processing?

Knowing the melting point of steel helps me make informed decisions throughout the processing stages. It allows me to set precise temperatures for welding, casting, and heat treatment, ensuring the material doesn’t weaken or lose its structural integrity. By understanding this property, I can choose the right steel alloy for high-temperature applications, improving both efficiency and safety in my projects. This knowledge is essential for maintaining quality control and achieving consistent results in manufacturing.

What safety considerations are related to steel’s high melting point?

Steel’s high melting point, typically around 2,500°F (1,370°C), requires careful safety measures to manage the extreme temperatures during processing. Workers must use specialized protective equipment, including heat-resistant gloves, face shields, and insulated clothing, to prevent burns from molten metal and radiant heat. Proper ventilation systems are critical to avoid exposure to toxic fumes and gases released during heating. Additionally, maintaining strict temperature controls and using advanced monitoring equipment can mitigate risks of overheating, which could lead to equipment failure or workplace accidents. Adhering to these precautions ensures a safer environment when handling steel at high temperatures.

How do steel’s melting points compare to other metals?

Steel’s melting point is significantly higher than many other common metals. For example, aluminum melts at around 1,221°F (660°C), and copper at approximately 1,984°F (1,085°C), which are both notably lower than steel’s 2,500°F (1,370°C). However, metals like tungsten, with a melting point of 6,192°F (3,422°C), far exceed steel in heat resistance. This comparison highlights steel’s advantageous thermal stability while also illustrating how it fits within the broader range of industrial metals.

Which metal has the lowest melting point compared to steel?

Among commonly used metals, mercury has the lowest melting point at -37.89°F (-38.83°C), making it unique as a liquid at room temperature. Comparatively, this is vastly lower than steel’s melting point of 2,500°F (1,370°C). Gallium also has a notably low melting point of approximately 85.57°F (29.76°C), allowing it to liquefy in the palm of your hand. These metals are often used in specialized applications where their low melting points are advantageous, contrasting sharply with steel’s high thermal resistance.

How does steel’s melting point compare to other common alloys?

Steel has a melting point of around 2,500°F (1,370°C). This is relatively high when compared to most alloys. For example, aluminum alloys melt, due to the properties of aluminum, at temperatures between 865°F and 1,240°F (463°C to 671°C). Copper alloys such as bronze and brass have melting points of 1,675°F to 1,980°F (913°C to 1,082°C), which is still lower than steel, but higher than aluminum alloys. Titanium alloys, known for their strength and heat resistance, have melting points around 3,034°F (1,668°C) which is slightly higher than that of steel. This range illustrates the superior thermal stability of steel, proving its strength and heat tolerance exceeds that of many materials, which enhances its value for industrial and structural applications.

References

Frequently Asked Questions (FAQ)

Q: What is the melting point of metal, specifically steel and stainless steel?

A: The melting point of metal varies, with steel melting at approximately 1370 degrees Celsius (2500 degrees Fahrenheit) and stainless steel melting at around 1400-1450 degrees Celsius (2550-2650 degrees Fahrenheit). These temperatures can vary slightly depending on the specific alloy composition.

Q: How does the melting point of metal change between different metals?

A: Different metals have different melting points due to variations in their atomic structure and bonding. For example, the melting point of copper is about 1085 degrees Celsius (1985 degrees Fahrenheit), whereas the melting point of brass, an alloy of copper and zinc, is around 900-940 degrees Celsius (1650-1725 degrees Fahrenheit).

Q: How do celsius and fahrenheit compare when discussing the melting point of a metal?

A: Celsius and Fahrenheit are two scales for measuring temperature, and they can be converted using the formula: Fahrenheit = (Celsius × 9/5) + 32. When discussing the melting point of a metal, it’s essential to specify which scale is being used to avoid confusion.

Q: What factors affect the melting point of a metal?

A: Several factors can affect the melting point of a metal, including its purity, the presence of other elements (as in alloys), and ambient pressure. Impurities and alloying can significantly alter a metal’s melting point by disrupting atomic bonds.

Q: How is the melting point of any metal determined?

A: The melting point of any metal is determined using precise laboratory techniques, such as differential scanning calorimetry, where the metal is gradually heated, and the temperature at which it transitions from solid to liquid is recorded.

Q: Why do metals have different melting points?

A: Metals have different melting points because of variations in their atomic structure, bonding energy, and electron configuration. These factors influence how much energy is required to break the bonds between atoms, which in turn affects the melting point.

Q: What metal has the highest melting point?

A: Tungsten is the metal with the highest melting point, at approximately 3422 degrees Celsius (6192 degrees Fahrenheit). This high melting point makes tungsten suitable for applications involving extreme heat.

Q: How does the melting point of an alloy, like steel, differ from that of a pure metal?

A: Alloys like steel often have lower melting points than pure metals due to the presence of multiple elements that disrupt the orderly atomic structure, making it easier for the metal to transition from solid to liquid.

Q: What should be considered when choosing a metal based on its melting point?

A: When choosing a metal based on its melting point, factors such as the operating environment, required mechanical properties, and cost should be considered. The metal’s melting point is crucial in applications like metal fabrication and high-temperature environments.