Various options are available when looking for a steel grade perfect for knife making. However, there’s always one grade that is a consistent favorite amongst the public, and that’s 1095 steel. 1095 steel is known to be a remarkable steel, and the reason behind this is the durability, edge retention, and ease of sharpening 1095 steel blades. But is this the best choice for your knife’s blade? In this blog post, we’ll analyze the steel that blacksmiths adore and focus on the factors that make 1095 steel’s advantages and limitations so unique. Regardless of whether you’re an amateur smith planning to fashion your very first blade or a professional, this post aims to equip you with everything you need to arrive at an educated choice for your knife-making requirements.

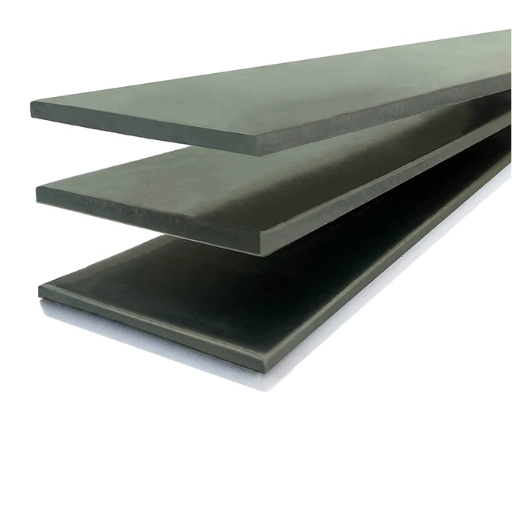

What is 1095 Steel?

Also, on the other hand, 1095 steel is considered a form of high carbon steel as it has about 0.95% of carbon, guaranteeing that it remains rigid and durable, two qualities every knife maker looks for in a blade. In any case, most people would prefer 1095 steel because of the durability it offers, plus its edge retention guarantees that this grade will remain the gold standard for blades. Unfortunately, as with everything in this world, 1095 steel does come with its side of disadvantages: its susceptibility to rust because of the high carbon content.

Understanding the Chemical Composition

The key components of 1095 steel consist of iron and carbon, with an average carbon value of 0.95% by weight. This remarkable sharpness retention and high hardness value of 1095 steel can be attributed to its increased carbon content. Other elements are also present in minor quantities which may affect the properties of 1095 steel:

- Manganese (0.30-0.50%): It increases the strength, hardenability, and wear resistance of 1095 steel. Furthermore, it helps improve the steel’s total heat treatment capability.

- Phosphorus (Max 0.04%): It offers strength in small amounts, but its high containment renders it brittle and thus needs to be controlled.

- Sulfur (Max 0.05%): Generally available in small portions, helps improve machining capabilities, but may slightly reduce overall toughness.

Due to the absence of considerable amounts of chromium or other alloys, 1095 steel does not have sufficient corrosion resistance, which makes rust control necessary. However, due to its uncomplicated composition, 1095 steel is preferred for the traditional forging and heating process. The high hardness level achieved by knife makers with 1095 steel makes their work simpler, along with simple processes such as heat treatment. In addition, due to its edge retention ability, it is suitable for cutting tools that require high durability.

Why Choose High Carbon Steel?

High carbon steel, for example, 1095 steel, is widely recognized for its unique properties and performance in numerous applications. Here are five reasons why high carbon steel should be your first choice:

- Exceptional Hardness of High-Carbon Steel

High-carbon steel tools and knives are some of the best in the world owing to their extraordinary sharpness. They can superbly fulfill rugged requirements because the carbon content in high-carbon steel, which is usually above 0.6%, allows it to be recognized as one of the hardest materials in the world.

- Cutting Edge Retention

Due to high carbon steels maintaining hardness, they can maintain a sharp edge for a considerably longer period of time than other metals that require constant sharpening. This is especially beneficial for industrial blades, outdoor knives, and kitchen knives.

- Sharpening Ease

High-carbon steel provides edge retention and is still simple to sharpen when the time arises. This combination of sharp edge retention and ease of sharpening makes high-carbon steel one of the most sought-after steels by professionals and enthusiasts.

- Versatile durability

High-carbon steel can withstand a lot of stress and impacts and is capable of enduring a lot of deformation from stress, which is the primary reason why it is renowned for its strength and stability. It also helps maintain sturdy, long-lasting, and dependable tools made from it.

- Cost-effectiveness

The use of hand-forged knives and tools in industrial-grade equipment is made possible due to the low costs associated with high carbon steel compared to high alloy steel grades.

Due to its dependable and high-performance quality traits, high carbon steel is often preferred by blacksmiths, knife makers, and other manufacturers.

The Role of Carbon Content in Performance

Carbon content is significant for performance because it affects the steel’s hardness, strength, and wear resistance. From my experience, having more carbon content usually increases the durability and hardness of the steel; however, it may also reduce ductility and toughness. Finding a suitable blend is essential to ensure the material works well for its intended use. For example, I have seen that tools needing sharp edges benefit from higher carbon content, whereas those that need flexibility may be more suited to medium carbon content.

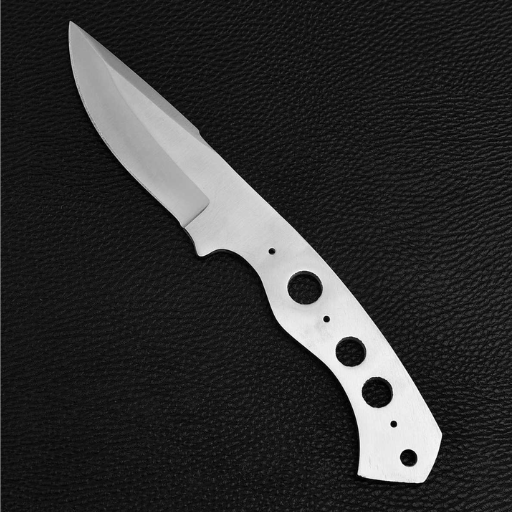

How is 1095 Steel Used in Knife Making?

1095 steel is a common material used for making knives because it has a high carbon content, which makes it hard, durable, and able to retain sharp edges. It is used for making hunting and survival knives and everyday carrying blades. Its sharpness allows it to cut precisely, but its softness will enable it to be sharpened relatively easily, making it useful for everyday wear. That said, its performance and durability are subject to proper care, as failure to do so would make it prone to rust.

Benefits of 1095 Steel for Blades

| Key Point | Details |

|---|---|

| High Carbon Content | 0.95% carbon ensures excellent edge retention. |

| Superior Hardness | Provides durability and long-lasting sharpness. |

| Edge Retention | Maintains sharpness even with heavy use. |

| Ease of Sharpening | Easily honed to a razor-sharp edge. |

| Wear Resistance | Withstands tough tasks without dulling quickly. |

| Versatility | Suitable for kitchen, utility, and outdoor knives. |

| Affordable | Cost-effective for high-performance blades. |

| Maintenance Required | Needs oiling to prevent rust and corrosion. |

Is 1095 Steel Easy to Heat Treat?

The ease with which bladesmiths and knife makers face during the heat treating of 1095 Steel makes it favorable among their tools. Keeping it relatively easy during the compositional level allows for the results of heat treatment to increase consistently. This helps improve the 1095 steel’s hardness, edge retention, and overall durability. Below are five benefits resulting from the heat treating of 1095 steel:

- High Carbon Composition

A fairly high concentration of carbon, 0.95 percent in 1095 steel, reacts positively to heat. This enables bladesmiths to attain greater levels of blade hardness with an appropriate heat treatment, making it easier to achieve sharp and durable edges.

- Easily Annealed

Softening the 1095 steel even further enables easier shaping and working before the hardening stage is reached. For bladesmiths, this step greatly simplifies blade customization.

- Defined Hardening Mechanism

Also known as the transformation range of steel, the hardening boundaries are very reliable in 1095 steel. The steel can easily be heated to critical temperatures ranging from 1475 F to 1500 F and it will convert to a more complex structure with oil quenching.

- Tempering

Like other steel types, quenching also makes 1095 steel more durable. Allowing the retention of hardiness to persist enables versatility towards tasks, and it’s said to improve upon tempering for effectiveness. The tempering range can also fit various blade specifications.

- Cost-Effective Heat Treatment Techniques

The process of heat treating 1095 steel does not require costly tools or sophisticated methods. It is economical for both small craftsmen and large-scale manufacturers while providing exceptional results.

Managing the heat treatment of blades made with 1095 steel optimally balances hardness, toughness, and edge retention. Careful attention and the right measures at each step will achieve a high level of quality in the final product.

Everyday Knife Types Using 1095 Blades

| Knife Type | Key Features |

|---|---|

| Survival Knives | Durable, easy to sharpen, tough for outdoors. |

| Bushcraft Knives | Ideal for carving, splitting, and fire prep. |

| Tactical Knives | Designed for combat and utility tasks. |

| Hunting Knives | Excellent for skinning and field dressing. |

| Fixed Blade Knives | Reliable for heavy-duty cutting tasks. |

| Folding Knives | Compact, versatile for everyday carry. |

| Military Knives | Built for rugged and demanding use. |

What are the Advantages of 1095 Carbon Steel?

1095 carbon steel is widely used in knife making because it is highly beneficial and effective. Careful maintenance of the blade allows for sustaining its sharpness over a long time, making the 1095 steel grade particularly useful. Moreover, the steel’s ease of sharpening offers maintenance simplicity even from amateur users. Furthermore, if the steel is heat-treated, it possesses enhanced toughness and edge-holding during machining. This makes 1095 carbon steel an exceptional steel grade, particularly regarding functional knives, as it is affordable, strong, sharp, and durable.

Exploring Hardness and Sharpness

Beneath the blades’ wear-resistant layer, the remaining steel should have a softer microstructure to maintain ductility. This is essential for optimal hardness and sharpness in blades and is dictated by the level of carbon alongside heat treatment; increased strength tends to improve edge retention, while softer edges enhance cutting efficiency and control.

Understanding Edge Retention

| Key Point | Details |

|---|---|

| Definition | Ability to maintain sharpness over time. |

| Steel Hardness | Harder steels retain edges longer. |

| Carbide Structure | Influences wear resistance and edge longevity. |

| Sharpening Angle | Lower angles improve sharpness, but reduce durability. |

| Cutting Surface | Softer boards (wood/plastic) reduce edge wear. |

| Maintenance | Regular honing and proper storage are essential. |

| Heat Treatment | Optimizes steel properties for edge retention. |

| Material Choice | High-carbon steels excel in sharpness retention. |

Resistance to Corrosion and Rust

1095 carbon steel is known for its strength and sharpness. However, it is not resistant to rust or corrosion. This article will discuss five ways 1095 carbon steel can resist rust and corrosion. Care and maintenance are necessary for any type of steel, and 1095 carbon steel is no exception.

- Applying oil or wax to the steel helps prevent moisture and oxygen from contacting its surface, protecting it from rust.

- Lack of humidity helps diminish rust formation. Proper air circulation can offer even more protection.

- Contaminants that cause rust should be removed, especially after contact with water or acid. Drying the surface also helps diminish rust formation.

- Mineral oil and other anti-corrosion compounds can help forge additional resistance to rust and abrasion.

- Continuous exposure to water or acid can significantly increase the speed at which a blade rusts. Minimizing time in these conditions can help lessen the rate of corrosion.

These tips will help enhance the performance, lifespan, and sleek aesthetic of 1095 carbon steel blades.

How Does 1095 vs 1075 Steel Compare?

| Parameter | 1095 Steel | 1075 Steel |

|---|---|---|

| Carbon Content | 0.95% | 0.75% |

| Hardness (HRC) | 58-65 | 55-60 |

| Edge Retention | Excellent | Good |

| Toughness | Moderate | High |

| Ease of Sharpening | Harder to sharpen | Easier to sharpen |

| Corrosion Resistance | Low | Low |

| Wear Resistance | High | Moderate |

| Weldability | Poor | Good |

| Applications | Kitchen knives, cutting tools | Outdoor knives, impact tools |

| Cost | Higher | Lower |

Differences in Carbon Content

The major difference between 1095 and 1075 steel is carbon content, which dramatically changes the properties and performance of the two types of steel. 1095 steel has a carbon content of about 0.90-1.03%, which is higher than the 0.70-0.80% of carbon present in 1075 steel. The increased level of carbon in 1095 steel increases hardness and edge retention, making it preferable for blades designed for precision cutting and durability.

The higher carbon content in 1095 steel increases its brittleness, especially under high stress or impact. This is not the case with 1075 steel, which, because of its slightly lower carbon content, has better toughness and is more resistant to chipping or breaking. This characteristic makes 1075 ideal for uses where the blade will likely suffer large amounts of wear and impact, like machetes and other chopping tools.

The varying amounts of carbon also affect the processes of heat treatments. 1095 steel can achieve as high as a Rockwell Hardness (HRC) of 66 after proper heat treatment, which is higher than 1075’s 55-58 HRC. While 1095 offers better edge performance, it is more prone to corrosion due to low alloying elements and requires more frequent maintenance than 1075, which is mildly forgiving in this aspect.

Considering a blade’s function, it is critical to use the appropriate kind of steel, as both 1095 and 1075 have different cutting capabilities. For tasks necessitating careful cutting, sharp edges, and stem thickness, 1095 steel is better suited. On the other hand, if the tool requires impact resistance, then 1075 steel is the most suitable selection as it has greater toughness.

Which is Better for Knife Making?

| Steel Type | Key Strength | Key Weakness | Best Use |

|---|---|---|---|

| 1095 Steel | Superior edge retention | Brittle, prone to rust | Kitchen knives, precision tools |

| 1075 Steel | High toughness, easy sharpening | Lower edge retention | Outdoor, survival knives |

| 5160 Steel | Excellent toughness, flexibility | Lower edge retention, rust-prone | Swords, heavy-duty outdoor tools |

Price and Performance Differences

When it comes to knife making, steel 1075 may be the most budget-friendly option, but in terms of quality still doesn’t get the job done compared to 1095. The difference in cost can generally be justified by the difference in manufacturing difficulty since 1075 steel contains less carbon. On average, 1075 steel is about 2.50to4.00perpoundcomparedto1095’s2.50to4.00perpoundcomparedto1095’s4.00 to 6.50, depending on market demand and supplier. The price disparity makes steel 1075 a better option for high-impact tool projects or when used in bulk.

In terms of performance, 1095 steel has edge retention and hardness, due to its higher carbon content of roughly 0.95%. Because of these features, it is well suited for fine-edged knives or specialized tools requiring a keen edge. Its remarkable hardness yields diminished toughness and increased brittleness. Conversely, 1075 steel, at 0.75% carbon content, provides greater toughness and increased resilience, making it an agile steel for sturdy heavy-duty or combat knives designed to endure significant impact and stress.

Factory operations focusing on components like forging and grinding may value 1075 for its ease of processing as it increases productivity. While 1095 certainly requires skill, particularly during heat treatment to mitigate warping or cracking, the end product is a knife designed for tasks where sharpness and durability are crucial.

This comparison has no clear winner as preference heavily relies on the intended use, budget constraints, and a blend of edge performance and toughness. For precision-focused tools, 1095 steel makes sense for investment. For broader or rugged applications, 1075 provides a compelling mix of performance and cost.

What are Best Practices for Heat Treatment of 1095 Steel?

| Step | Details |

|---|---|

| Normalization | Heat to 1500-1600°F, cool in still air. |

| Quenching | Heat to 1475°F, quench in 120°F oil. |

| Tempering | Heat to 400-500°F, hold for 2 hours. |

| Preheat Oil | Preheat quenching oil to 120°F. |

| Avoid Overheating | Prevent grain growth by controlled heating. |

| Check Hardness | Use a file or Rockwell tester post-quench. |

| Repeat Tempering | Perform tempering twice for consistency. |

| Safety Gear | Use gloves, tongs, and ensure ventilation. |

Steps to Properly Heat Treat

- How to Heat Treat 1095 Steel

Start by normalizing the 1095 steel to relieve any internal stresses. Heat the steel to about 1600°F or 870°C and allow it to cool in still air. This aids in uniformity within the steel, which further promotes optimal heat treatment results.

- Austenitize

Now, continue the process by raising the temperature between 1475°F and 1500°F. Maintain the temperature for 5-10 minutes to ensure the steel reaches a uniform austenite phase. This allows further tuning of the steel for the hardening process in further steps. Take care not to overheat, which can lead to grain growth and reduced toughness.

- Quenching

Following austenitizing, harden the steel by rapidly quenching it to lock the microstructure in a rigid form. For 1095 steel, it is best to use oil, as rapid oil quenching minimises the risk of cracking while still achieving high hardness. The ideal oil temperature should be preheated to 120°F or 140°F. It is critical to ensure that the steel is fully immersed in the oil and agitated appropriately to ensure consistent cooling.

- Cryogenic Treatment (Optional)

A cryogenic treatment can be performed to achieve maximum hardness and convert the retained austenite into martensite. It includes cooling the steel in a bath of liquid nitrogen or dry ice after quenching for several hours. While not mandatory, it can improve wear resistance and stability in tools that experience extreme stress.

- Tempering

Tempering is essential for reducing brittleness and increasing toughness in 1095 steel. In this case, you need to heat the steel to a tempering temperature between 400°F and 600°F (200°C —315°C), depending on the impact resistance and hardness. Higher tempering temperature causes lower hardness but yields tougher steel, while hollower tempering yields harder brittle steel (62 HRC). Thermal expansion will be proportional to time, sufficient greater than 60 minutes for each inch of thickness, and air cooling will occur post-heating.

- Stress Relieving (Optional)

Depending on the intended application, a secondary stress-relief cycle at a lower temperature around 300°F can be performed to customize the material and further reduce residual stress.

Following these steps enables knife makers and tool smiths to push the limits of 1095 steel to the performance extremes without sacrificing balance between hardness and durability.

Avoiding Common Heat Treatment Mistakes

The procedures related to the treatment of 1095 steel require careful focus on details that, if overlooked, can lead to problems in the treatment results. Here are five such frequent problems one can make together with their consequence:

- Steel Overheating

If the steel’s temperature is increased past the recommended mark during the heating phase, coarse grains will form. This will lower the steel’s toughness, which reduces the tools’ brittleness. Always paying close attention to the temperature and using a good thermometer or pyrometer will solve the problem.

- Incorrect Quenching Medium Used

Inserting oil instead of water as the quenching medium is a common fault that results in improper cooling and hardness. As a rule, stick to water quenching unless requirements dictate otherwise.

- Heating Steel Incorrectly

Tools subjected to uneven heating are likely to become warped or cracked. These flaws stem from stress and widely divergent hardness throughout the steel. Ensuring uniform heating with a calibrated kiln or forge with satisfactory circulation can solve the heating issue.

- Failure to Proceed to the Tempering Stage

Not conducting the tempering stage right after quenching the steel introduces unnecessary hardness, facilitating cracking over time. The best approach here is quenching followed by a tempered cycle to relieve stress and fortify the steel.

- Not Cleaning Properly Before Applying Heat Treatment

Effects of wrongdoing: Cleaning is needed to remove oil, grease, or moisture from the steel surface. Failure to do so will lead to oxidation or carbon loss during heating. Defects on the steel surface affect proper uniformity during heating.

If these problems are avoided, the quality of tools manufactured from 1095 steel is enhanced tremendously.

Tips from Professional Bladesmiths

- Getting Precise with Tempering Temperatures

According to seasoned bladesmiths, the optimal tempering temperature for the 1095 steel is between 400°F and 450°F. If you want a blade with a Rockwell Hardness (HRC) of 57-60, which provides good toughness while retaining an edge, then having the tempering around 450°F is ideal. To achieve perfect results, ensure you have an accurate thermometer for your oven or forge.

- Reduce Steel Hardness

It is advised to attempt normalizing the 1095 steel before undergoing the hardening process as part of the procedure. Expert bladesmiths recommend this. It basically means heating the metal to its critical temperature of about 1500°F and letting it cool in still air. This process relieves internal stresses and refines the grain structure of the steel, thus resulting in a sharper edge.

- Oil Is What Matters For Quenching

Unlike other professional bladesmiths, I believe that for 1095 steel, it is best to use fast oil like Parks 50 during the quenching stage. These oils ensure that the right cooling rate is achieved for the steel to be tempered without excessive warping or cracking. Although water quenching is the fastest method, it poses a greater risk of cracking the steel due to rapid temperature changes.

- Use The Right Grind Angles

From the expert bladesmiths’ point of view, your blade’s grind angle matters a lot regarding its performance. Generally, an angle of 20°-25° is preferred for multi-purpose blades. Meanwhile, for finer cutting tools like kitchen knives, professionals recommend increasing the thinness of the angle to about 15°-20° to make the knife sharper. Nevertheless, sharpened blades are less durable.

- Check If Your Logs Are Consistent Throughout The Process

Numerous professional bladesmiths stress the significance of maintaining a comprehensive log of your heat treatment process. Include details about the heating durations, temperatures, medium used for quenching, and parameters related to the tempering. With time, this log helps achieve consistent results and improves your techniques.

- Softness And Flexibility Testing

Having a Rockwell or another measuring tool is a necessity for some people. Invest in one if you want to measure the steel’s softness after treating it. Simple flex test advocates also recommend that the blade be bent a little on one of its sides. This way, you can ensure proper stiffness, low brittleness, and proper tempering.

By adhering to tested methodologies and these tips, novice bladesmiths using 1095 steel will achieve professional results. These insights guarantee the product’s best possible quality, durability, and function.

References

- Book Reference: “Steel metallurgy for the non-metallurgist” – Discusses the properties and behavior of 1095 steel in comparison to other carbon steels. Link to source

- Journal Article: “Effect of spraying time on mechanical and tribological performances of HVOF-sprayed WC–Co and WC–Cr3C2Ni coatings on AISI 1095 steel” – Explores the use of 1095 steel as a substrate in coating applications. Link to source

- Research Paper: “The influence of pearlite on Barkhausen noise generation in plain carbon steels” – Examines the microstructural properties of 1095 steel among other carbon steels. Link to source

Frequently Asked Questions (FAQ)

Q: What makes 1095 steel a popular choice for knife making?

A: 1095 steel is popular due to its high carbon content, approximately 0.95%. This gives the steel high hardness and the ability to hold an edge well, making it ideal for knife blades. It is also relatively easy to forge and sharpen, appealing to novice and experienced knife makers.

Q: How does 1095 steel compare to stainless steel?

A: While 1095 steel offers high hardness and edge retention, it lacks the corrosion resistance of stainless steel. Stainless steel is less likely to rust if not properly maintained, making it a better choice for kitchen knives and environments where moisture is a concern.

Q: Is 1095 steel tough enough for all types of knives?

A: 1095 steel provides good toughness for many knife designs, especially when properly heat-treated. However, it can be brittle compared to other alloys like d2 steel, which may be more appropriate for knives that require additional wear resistance and toughness.

Q: Can 1095 steel be used for kitchen knives?

A: Yes, 1095 steel can be used for kitchen knives, but it requires proper maintenance to prevent rust. Its high-carbon content provides excellent sharpness and edge retention, but it must be cleaned and dried after use to maintain its condition.

Q: What are the advantages of using D2 steel over 1095 steel?

A: Due to its higher chromium content, D2 steel offers better wear resistance and is less prone to corrosion than 1095 steel. This makes it a good choice for knife and tool applications where durability and low maintenance are essential.

Q: How should 1095 steel be maintained to prevent rust?

A: 1095 steel blades should be cleaned and dried thoroughly after use to prevent rust. Applying a light coat of oil can also help protect the blade from moisture. Proper storage in a dry environment is essential to maintain the blade’s condition.

Q: Why is proper heat treatment necessary for 1095 steel?

A: Proper heat treatment is crucial for 1095 steel as it enhances its toughness and reduces brittleness. This process ensures that the knife can hold an edge effectively while also being durable enough for various cutting tasks.

Q: How does 1095 steel compare to Damascus steel?

A: Damascus steel is known for its unique patterns and aesthetic appeal. It is often made by layering different types of steel, including high-carbon steel like 1095. While Damascus steel can incorporate the properties of 1095, it is typically valued more for its appearance than its performance characteristics.

Q: Are there any downsides to using 1095 steel for knife making?

A: The primary downside of using 1095 steel is its susceptibility to corrosion due to its lack of stainless properties. It also requires regular maintenance to prevent rust and can be more brittle than some other knife steels if not properly heat treated.

Q: What is the price difference between 1095 steel and other knife steels?

A: 1095 steel is generally more affordable than some high-end stainless and damascus steels. However, the price can vary based on the supplier and specific requirements for the knife design. Its cost-effectiveness makes it a popular choice for many knife makers.