Choosing cookware and flatware of excellent quality requires paying special attention to the materials used. 18/10 stainless steel is on top of the list of the best-performing, most durable, and most visually appealing cookware materials. But what does 18/10 mean, and why should it matter to you when buying new kitchen appliances? This article explains the composition, advantages, and distinct characteristics of 18/10 stainless steel and its enduring popularity among professional chefs and home cooks. Suppose you are in the market for a new set of kitchen tools or are just interested in the materials of your favorite utensils. In that case, this guide will help you understand why 18/10 stainless steel is an innovative and valuable purchase.

What is 18/10 Steel and Why is it Popular?

18/10 Stainless Steel is an alloy with 18% chromium and 10% nickel. The alloy’s chromium gives it durability and the ability to resist rust. Nickel increases its luster, means that it can further withstand acidic and alkaline substances, and, enhances its corrosion resistance. The material is popular in cookware and kitchen tools because it is nonreactive, meaning it does not change the taste of food or leach chemicals. Its durability, low maintenance, and elegant appearance make it a favorite among both professional and home cooks.

Composition of 18/10 Steel

| Key Component | Percentage Composition |

|---|---|

| Chromium | 18% |

| Nickel | 10% |

| Iron | 66-71% |

| Manganese | 2% |

| Silicon | 1% |

| Carbon | 0.07% |

| Nitrogen | 0.1% |

| Phosphorus | 0.045% |

| Sulfur | 0.015% |

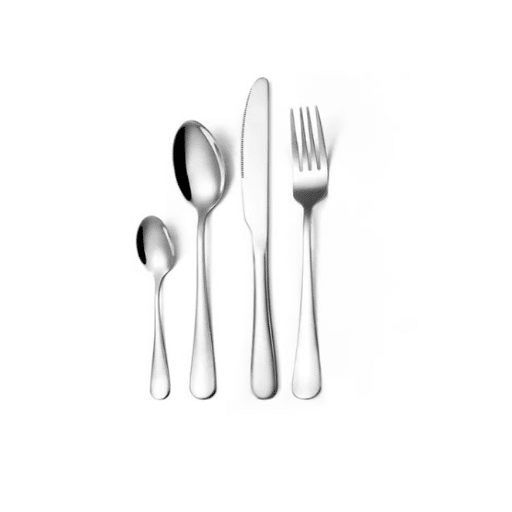

Why 18/10 Steel is a Preferred Choice for Flatware

18/10 stainless steel is highly favored for flatware due to its exceptional combination of durability, aesthetic appeal, and corrosion resistance. The decline in quality is caused by rubbing against food and other surfaces which causes scratches to appear. The “18/10” designation also refers to the composition of the material, meaning it has 18% chromium and 10% nickel. Chromium enhances the rust and tarnish resistance of the flatware; maintaining its quality even with daily use. Nickel will enhance the polished appearance and further increase the material’s ability to withstand acidic or alkaline environments.

18/10 steel flatware is known for its long-lasting polish and requires little maintenance which is one of its major benefits. With proper care, this type of flatware will not stain or lose its shine even after repeated washing or dishwasher cleaning, according to the industry’s observation. Moreover, scientific research also points out the corrosion resistance of 18/10 stainless steel, which makes it a good choice for increased exposure to water, acidic foods and kitchen environments like dining areas and food prep stations.

The desirable traits of 18/10 flatware also include its weight and balance. This type of flatware is usually on the higher end because it contains more nickel, adding to its density. This is also the reason for the luxurious feel associated with flatware made from this material. Such qualities make 18/10 steel a fundamental material for use in utensils at fine restaurants or homes where the owners are looking for sturdy and dependable kitchen tools. In addition to that, 18/10 steel flatware is consistently rated better than its counterparts, 18/8 or 18/0, when it comes to durability and appealing look based on consumer reviews and product evaluations.

With 18/10 stainless steel flatware, the dining table is sophisticated and functional. Its practicality mingled with elegance makes it suitable for both professional and domestic use. Whether you are setting a daily table or having an elegant dinner, 18/10 stainless steel speaks reliability and sophistication.

Advantages of Using 18/10 Steel

| Key Point | Advantage |

|---|---|

| Corrosion Resistance | Exceptional resistance to rust and corrosion. |

| Durability | High strength and long-lasting performance. |

| Aesthetic Appeal | Shiny, polished, and visually appealing. |

| Food Safety | Non-reactive with acidic or corrosive foods. |

| Heat Resistance | Withstands high temperatures effectively. |

| Ease of Cleaning | Dishwasher safe and easy to maintain. |

| Versatility | Suitable for cookware, cutlery, and appliances. |

How Does 18/10 Compare to Other Grades of Stainless Steel?

From the initial look, 18/10 stainless steel looks high-grade because it boasts better durability, rust resistance, and polish than the alternatives. With a marginally higher Nickel content than 18/8, it becomes more corrosion resistant and shinier. On the other hand, 18/0 stainless steel has no nickel, which, while cheaper, also eliminates rust resistance and wear strength. Out of all the choices, 18/10 has the best balance of function and crown jewels, making it ideal for high-quality flatware and cookware.

Different Grades of Stainless Steel Explained

Stainless steel can be divided into several grades, which we refer to as types. Each classification has distinct properties suited for different usages.

Below, we list five popular types of stainless steel, identifying their details and distinguishing features:

- 304 Stainless Steel (18/8)

Composition: 18% chromium, 8% nickel

Features: It has excellent, versatile characteristics, offering remarkable resistance to corrosion and durability. It’s in high demand in the industry for kitchenware and sinks.

- 316 Stainless Steel

Composition: 16% chromium, 10% nickel, 2% molybdenum

Features: Has best resistance towards corrosion, especially in salt, seawater, or other tough chemical environments. Primarily used in marine and medical equipment.

- 430 Stainless Steel (18/0)

Composition: 18% chromium, 0% nickel

Features: It’s more affordable and magnetic, but compared to other grades, it offers lesser resistance to corrosion. It’s commonly utilized in low-cost kitchen items and decorative kitchenware.

- 410 Stainless Steel

Composition: 11.5%-13.5% chromium

Features: It’s Industrial Strength and tough. Compared to other grades, it’s moderately resistant to corrosion. For most utensils, tools, and cutlery, it’s the preferred grade.

- 201 Stainless Steel

Composition: Features lower nickel and higher manganese in comparison to 304

Features: Used in kitchen appliances that are lightweight or in outdoor equipment. Considered a cost-sensitive stainless steel option, displaying decent resistance to corrosion and moderate strength.

Each type is configured that way, balancing every attribute to make the material suitable for the desired environment and use.

Comparing 18/10 with Grade 304 and 316

| Parameter | 18/10 Stainless Steel | Grade 304 Stainless Steel | Grade 316 Stainless Steel |

|---|---|---|---|

| Chromium Content | 18% | 18-20% | 16-18% |

| Nickel Content | 10% | 8-10.5% | 10-14% |

| Molybdenum Content | None | None | 2-3% |

| Corrosion Resistance | Excellent | Good | Superior |

| Pitting Resistance | Moderate | Moderate | High |

| Cost | Moderate | Affordable | Expensive |

| Applications | Cookware, cutlery | Kitchen, food processing | Marine, chemical industries |

| Heat Resistance | Up to 870°C | Up to 870°C | Up to 927°C |

| Weldability | Excellent | Excellent | Excellent |

| Durability | High | High | Very High |

18/10 Steel vs. Other Types of Stainless Steel

| Parameter | 18/10 Steel | 18/8 Steel | 18/0 Steel |

|---|---|---|---|

| Chromium Content | 18% | 18% | 18% |

| Nickel Content | 10% | 8% | 0% |

| Corrosion Resistance | High | Moderate | Low |

| Durability | Excellent | Good | Moderate |

| Shine/Luster | High | Moderate | Low |

| Heat Resistance | High | Moderate | Low |

| Magnetic Properties | Non-magnetic | Non-magnetic | Magnetic |

| Cost | High | Moderate | Low |

| Common Uses | Premium cookware, flatware, appliances | General cookware, utensils | Budget flatware, basic kitchen tools |

Is 18/10 the Best Quality for Cookware?

Foodies find 18/10 stainless steel one of the best materials for cookware because of its waterproof, durable, and non-reactive surface. Its high chromium and nickel content gives it polishing and stain-resistant attributes. Other grades like 304 and 316 may suit different needs, but 18/10 stands out for the balance of quality and aesthetic appeal, thus making it the premium choice.

Why Choose 18/10 for Stainless Steel Cookware

The selection of 18/10 stainless steel in cookware is deliberate. It combines resistance to rust and staining with a polished finish, which increases the cookware’s durability. It assures that my pots and plates remain in top condition for years with a non-reactive surface, making it easy to preserve the natural flavors of food. It gives me an ideal balance of performance and appeal.

Benefits in Cooking with 18/10 Steel

| Key Benefit | Description |

|---|---|

| Corrosion Resistance | Resists rust and corrosion effectively. |

| Durability | Long-lasting and highly durable material. |

| Heat Retention | Retains and distributes heat evenly. |

| Non-Reactive Surface | Safe for acidic and alkaline foods. |

| Easy Maintenance | Simple to clean and dishwasher safe. |

| Aesthetic Appeal | Polished, shiny, and visually appealing. |

| Versatility | Suitable for various cooking methods. |

| Non-Toxic | No harmful chemicals leach into food. |

| High-Temperature Tolerance | Handles extreme heat without damage. |

| Professional Quality | Trusted by chefs and home cooks alike. |

Considerations When Buying 18/10 Cookware

| Key Consideration | Details |

|---|---|

| Material Quality | Ensure 18/10 grade for durability and safety. |

| Heat Distribution | Look for multi-ply or clad construction. |

| Weight | Heavier pans indicate better quality. |

| Handles and Lids | Opt for sturdy, heat-resistant designs. |

| Induction Compatibility | Check for a magnetic stainless steel base. |

| Maintenance | Easy to clean and resistant to corrosion. |

| Budget | Higher quality often means higher cost. |

| Cooking Needs | Suitable for high-heat and versatile cooking. |

What Makes 18/10 Stainless Steel Flatware Durable?

The composition of 18/10 scratch-resistant flatware gives it durability. It combines 18% of chromic for outstanding rust resistance and 10% of polished nickel for added strength. This makes the flatware last for wear and tarnish while facing regular bends with maintenance to maintain its appearance over time.

Role of Nickel in Durability

Nickel helps stainless steel 18/10 flatware last a long time because it further strengthens its corrosion resistance, making it resistant to scratches and tarnishing and giving it a lifetime shine.

Impact of Chromium Content on Corrosion Resistance

The chromium content is of utmost importance in stainless steel since its greatest contribution comes from corrosion resistance. Normally, stainless steel has 10.5% chromium, which allows a thin layer of oxide to be formed on its surface. This oxide layer, also known as the ‘passive layer’, serves as a shield against moisture and oxygen, the main culprits in rust and corrosion.

Research proves that increasing the percentage of chromium in stainless steel helps it withstand harsh conditions such as saltwater, acidic solutions, and even industrial-grade chemicals. For instance, research claims that 18% chromium-containing stainless steel, like 18/10 stainless steel flatware, is extremely tough and resistant to pitting, staining, and corrosion. The reason is that the alloy can heal itself and get redrawn with a chrome layer, which gets rid of the majority of scratches.

According to the metallurgy data, the optimum amount of chromium for balancing the resistance to corrosion and mechanical properties is between 16% and 20%, which is why it is a norm in premium flatware. This exact blend guarantees durability while maintaining the stainless steel’s beauty and usefulness, even with routine and intense wear and tear.

Ensuring Longevity of 18/10 Flatware

Careful maintenance and handling of 18/10 stainless steel flatware ensures that it remains visually appealing and retains its corrosion-resistant properties. Below are practices proved to be effective for preserving the flatware’s durability and performance:

- Thorough Cleaning

Always rinse the flatware after use, especially if it contains acidic or salty food. If not taken care of immediately, these residues can corrode the surface of flatware. Soaking also impacts the surface of the alloy; hence, it should be avoided, along with prolonged soaking.

- Avoid Strong Detergents

Avoid using strong dishwashing detergents that contain chlorine or other strong chemicals. These detergents may erode the protective layer over time while also preserving the luster of the flatware. Gentle products do a great job of maintaining shine and protecting the surface.

- Cleaning Techniques

Although handwashing is preferred, ensure that overloaded dishwashers do not stack other types of metal with the flatware, as this leads to side scratching. If dishwashing is used, place the utensil handles up, resulting in more complete washing.

- Polishing and Drying

To maintain shine, the flatware should be dried with a soft cloth immediately after washing. This prevents water spots and guarantees that the protective layer remains intact.

- Safe Storage

To avoid bending or scratching, flatware should be kept in a dry area, such as a custom cutlery organizer. It should also be stored away from moist places because humidity increases the risk of tarnishing.

Taking the above precautions will allow 18/10 flatware to maintain its reliability, elegance, striking appearance, durability, and quality for years, making it a stunning piece for any table setting.

How Does 18/10 Steel Resist Corrosion?

Corrosion is less likely with the 18/10 steel because it has a high chromium content. The 18% chromium in the steel adds an oxide layer, which mitigates rusting and oxidation.The 10% nickel and moisture-resistant metals further sturdily bond the steel, allowing it to maintain its shine. This ensures the steel requires little maintenance, improving its lifespan while also making it useful for aesthetic purposes.

Understanding Corrosion Resistance in 18/10

| Key Point | Description |

|---|---|

| Chromium Content | 18% forms a protective oxide layer. |

| Nickel Content | 10% enhances corrosion resistance and strength. |

| Resistance to Rust | Excellent in humid and moist environments. |

| Pitting Resistance | Moderate, not ideal for chloride exposure. |

| Self-Healing Surface | Oxide layer repairs itself when scratched. |

| Non-Reactive Surface | Safe for acidic and alkaline foods. |

| Durability | Long-lasting under regular use conditions. |

| Aesthetic Appeal | Shiny, polished, and resistant to tarnishing. |

| Limitations | Not suitable for extreme chloride environments. |

| Maintenance | Easy to clean and maintain, rust-free surface. |

Role of Chromium and Nickel in Preventing Rust

| Element | Role in Preventing Rust | Key Features |

|---|---|---|

| Chromium | Forms a protective oxide layer (Cr2O3). | Self-repairs when scratched; resists oxygen. |

| Nickel | Enhances toughness and corrosion resistance. | Effective in acidic and chloride environments. |

Maintaining Stainless Steel to Avoid Oxidation

Stainless steel’s shine and resistance to rust is maintained through proper care. Outlined below are five helpful but straightforward rules to follow to maintain stainless steel:

- Cleaning

To maintain a spotless steel surface, we recommend cleaning it using soap and water. Thorough cleaning removes oil, grease, and grime, which can further mar the surface. For better results, dry the surface with a lint-free soft towel to mitigate the formation of water stains.

- Prevention of Scratches

When scrubbing stainless steel, use non-abrasive sponges or microfiber cloths, as any rough paste or putty increases the chances of scratching it, leading to rust.

- Occasional Shining

Apply stainless steel shine or polish to the surface every now and then. This will make the surface shiny and protect it against tarnishing.

- Immediate Spill Cleanup

Some spills, such as those with chlorides or acidic constituents, should be cleaned up immediately to avoid etching or corrosion on the surface.

- Environmental Protection

Limit the exposure to Coastal Air or other chloride-rich environments by adding more defense structures or protective layers.

References

- Wiley Online Library:

Article: “Release of nickel and chromium in common foods during cooking in 18/10 (grade 316) stainless steel pots”

Link to source - Aston University Repository:

Thesis: “Preferred Orientation in 18/10, 18/12 and 18/14 Chromium/Nickel Steels and its Relation to Tensile and Press Forming Properties”

Link to source - Steel Founders’ Society of America (SFSA):

Document: “The Naming and Numbering of Stainless Steels”

Link to source

Frequently Asked Questions (FAQ)

Q: What is 18/10 stainless steel and why is it essential for cookware and flatware?

A: 18/10 stainless steel is a type of stainless steel grade that contains 18% chromium and 10% nickel. It is essential for cookware and flatware because it is highly resistant to corrosion and rust, making it durable and safe to use for utensils like forks, spoons, and knives.

Q: How does the nickel content affect the quality of stainless steel?

A: The amount of nickel in stainless steel enhances its corrosion resistance and adds to its strength and durability. Nickel content helps make the stainless steel surface and protects it from rust and corrosion, which is crucial for long-lasting cookware and flatware.

Q: What is the difference between 18/10 and other types of stainless steel used in cookware?

A: The main difference lies in the composition. 18/10 stainless steel contains 18% chromium and 10% nickel, while other types like 18/8 stainless steel consist of 18% chromium and 8% nickel. The higher nickel content in 18/10 makes it more corrosion-resistant and a better choice for high-quality cookware and flatware.

Q: Why is chromium added to stainless steel?

A: Chromium binds to the stainless steel, creating a thin layer of oxide on the surface that protects it from rust and corrosion. This makes the stainless steel more durable and suitable for use in environments exposed to moisture and heat, such as cooking utensils and kitchenware.

Q: Is 18/10 stainless steel safe to use for cooking?

A: Yes, 18/10 stainless steel is safe to use for cooking. It is non-reactive, meaning it won’t leach harmful chemicals into food, and its resistance to rust and corrosion ensures that it remains hygienic over time.

Q: How can I identify if my cookware is made from 18/10 stainless steel?

A: You can identify 18/10 stainless steel cookware by checking the product labeling or description. Manufacturers often indicate the stainless steel grade, and you may see “18/10” stamped on the bottom or packaging of the pots and pans.

Q: What are the benefits of using 18/10 stainless steel in cutlery?

A: The benefits of using 18/10 stainless steel in cutlery include its high resistance to corrosion and rust, which ensures longevity and maintains a polished appearance. It is also strong and durable, making it ideal for daily use in forks, spoons, and other utensils.

Q: Can 18/10 stainless steel be used in saltwater environments?

A: While 18/10 stainless steel is highly resistant to corrosion, prolonged exposure to saltwater can lead to less resistant conditions. If saltwater exposure is frequent, additional alloys like molybdenum might be added to stainless steel to enhance its resistance.

Q: What makes type 304 stainless steel a common choice for cookware?

A: Type 304 stainless steel, which includes 18/10 stainless steel, is austenitic and highly resistant to rust and corrosion. Its composition of chromium and nickel makes it durable and safe for various cooking applications, making it a popular choice for high-quality stainless steel cooking utensils and cookware.