Selecting the appropriate material is critical for stainless steel’s durability, performance, and intended use. 18-8 and 304 are two variants often compared due to their similarities, but what differences set them apart? Whether industrial-grade, food-safe equipment, or household articles, versatile applications require understanding the differences between these stainless steels. This article aims to explain their distinct characteristics, uses, and main benefits so that informed choices can be made. Understanding the details will help customize your next design.

What is 18-8 Stainless Steel?

18-8 stainless steel is one of the most common alloys, consisting of 18% chromium and 8% nickel. This configuration offers excellent resistance to corrosion while still being durable and versatile, which allows it to be used in multiple industries. Due to its moisture, heat, chemical, and rust resistance, it is popular in kitchen utensils, industrial devices, and medical instruments.

Defining 18-8 Stainless Steel and Its Uses

| Aspect | Details |

|---|---|

| Definition | Stainless steel with 18% chromium, 8% nickel. |

| Other Name | Also known as 304-grade stainless steel. |

| Chemical Composition | 18% chromium, 8% nickel, trace carbon, mostly iron. |

| Corrosion Resistance | Excellent, but not ideal for saltwater exposure. |

| Magnetic Properties | Generally non-magnetic, may become slightly magnetic after cold working. |

| Strength | Tensile strength: 80-200,000 psi. |

| Hardenability | Hardened only through cold working. |

| Density | 7.9 g/cm³. |

| Melting Point | 1400-1450°C (2552-2642°F). |

| Applications | Kitchenware, medical devices, food processing, architecture, and automotive. |

| Advantages | Durable, corrosion-resistant, aesthetic, recyclable, versatile. |

| Disadvantages | Expensive, needs maintenance, and has limited high-temperature performance. |

Properties and Corrosion Resistance of 18-8

| Aspect | Details |

|---|---|

| Definition | Stainless steel with 18% chromium, 8% nickel. |

| Corrosion Resistance | Excellent in mild environments, not ideal for chlorides. |

| Magnetic Properties | Non-magnetic, slightly magnetic after cold working. |

| Tensile Strength | 515-620 MPa (80,000-90,000 psi). |

| Yield Strength | 205 MPa (30,000 psi). |

| Elongation | 40-70% elongation at break. |

| Density | 7.9 g/cm³. |

| Melting Point | 1400-1450°C (2552-2642°F). |

| Thermal Conductivity | 16-24 W/m·K. |

| Applications | Kitchenware, medical tools, food processing, and automotive parts. |

| Advantages | Durable, corrosion-resistant, recyclable, versatile. |

| Disadvantages | Susceptible to chloride pitting, requires maintenance. |

Applications in Fasteners and Other Industries

The versatility, mechanical strength, and resistance to corrosion shown by 18-8 stainless steel make it a go-to material for many industries, including manufacturing, construction, automotive, and aerospace. Fasteners are an essential part to machinery, and 18-8 stainless steel is used to manufacture screws, bolts, nuts, and washers. Because of the durability and resiliency of these fasteners, they are suitable for use in harsh environments, which include exposure to moisture, chemicals, and extreme temperatures.

Latest research suggests that 18-8 stainless steel will positively impact the steadily growing market for stainless steel fasteners, projected to increase from 6.79 billion in 2022. Withstanding rust and pitting in high salt environments is far less difficult with 18-8 stainless steel, making it beneficial to the marine and oil industries. Moreover, fasteners manufactured from 18-8 stainless steel are perfect for use in food and beverage machinery because 18-8 stainless steel is non-poisonous, easy to clean, and meets safety standards.

Apart from being used in fasteners, 18-8 is utilized in medical instruments, chemical processing machinery, and sections of buildings. For example, 18-8 is ideal for implants and surgical instruments because these devices undergo high-temperature sterilization. Also, 18-8 stainless steel is corrosion resistant to acidic and caustic substances, thus it is helpful in chemical plants where durable equipment is needed in harsh operating conditions. These applications highlight the importance of 18-8 stainless steel as a reliable material in different modern industries.

Exploring 304 Stainless Steel: A Comprehensive Guide

A while back, 304 stainless steel fuel tanks were developed in the aviation industry. The ease with which it can be welded, fabricated, and processed makes it easily manageable for any worker. 304 steel is commonly used in the construction industry because of its weight-to-strength ratio, which is highly favored. Stainless steel not only looks appealing but it is also easier to maintain, thus widely used in kitchen appliances. It’s no wonder this steel alloy is popular since it is relatively affordable and dependable, making it an ideal material for commercial and industrial use.

Characteristics of 304 Stainless Steel

| Aspect | Details |

|---|---|

| Definition | Austenitic stainless steel with 18% chromium, 8% nickel. |

| Corrosion Resistance | Excellent in oxidizing environments, resists most acids. |

| Magnetic Properties | Non-magnetic, slightly magnetic after cold working. |

| Tensile Strength | 505-750 MPa (73,200-108,800 psi). |

| Yield Strength | 215 MPa (31,200 psi). |

| Elongation | 70% elongation at break. |

| Density | 8.0 g/cm³. |

| Melting Point | 1400-1455°C (2550-2650°F). |

| Thermal Conductivity | 16.2 W/m·K. |

| Applications | Kitchenware, medical tools, food processing, and marine equipment. |

| Advantages | Durable, corrosion-resistant, weldable, versatile. |

| Disadvantages | Susceptible to chloride pitting, expensive. |

Advantages in Corrosion Resistance

In my view, the advantage of 304 stainless steel, having reasonable corrosion resistance, is due to its composition, especially chromium’s presence. This particular element alone creates a passive layer that halts rust and oxidation from occurring even in places with high humidity or chemically distressed environments. Furthermore, its resistance to being oxidized and alkali makes it perfect for numerous uses where structural integrity and longevity are critical.

Common Uses in Kitchen Utensils and More

304 stainless steel is appreciated in various industries because of its remarkable attributes and dependability. Below are five common uses where its properties shine:

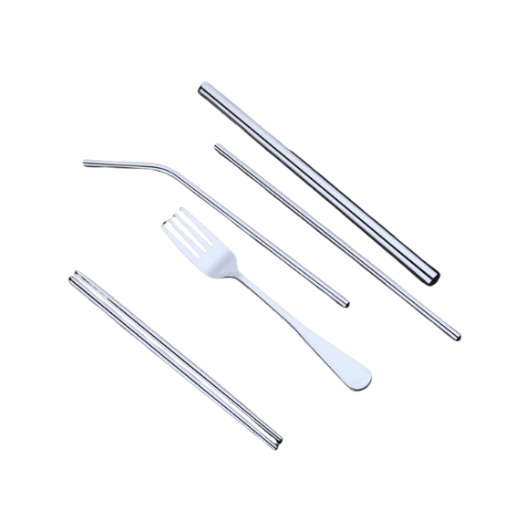

- Cooking Appliances and Utensils

- 304 stainless steel is non-reactive and durable, and is used in cutlery bowls and pans.

- Food never encounters a metallic flavor due to the non-reactive nature of the steel towards food acids.

- Devices

- The appliances also contain 304 stainless steel, which does not rust when exposed to water for long periods of time and can withstand high temperatures, making it useful for ovens.

- Food Composition and Preservation Equipment

- This grade of stainless steel is commercially used to construct tables, sinks, and conveyor belts, as it fulfills the scrubbing requirements.

- Scientific and Medical Instruments

- Surgical equipment like forceps and scalpels routinely use 304 stainless steel because it has to undergo multiple sterilization cycles, and the steel’s high corrosion resistance provides uninterrupted operation during them.

- Building and Design

- Due to its long lifespan, 304 stainless steel is used decoratively and in the construction of handrails and countertops. It is highly valued for its aesthetic properties and enduring strength against harsh conditions.

Comparing 18-8 vs 304 Stainless Steel

| Aspect | 18-8 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Definition | 18% chromium, 8% nickel composition. | 18% chromium, 8% nickel, with trace elements. |

| Corrosion Resistance | Good, but struggles in chloride environments. | Better than 18-8, but not ideal for saltwater. |

| Magnetic Properties | Non-magnetic, slightly magnetic after cold working. | Non-magnetic, slightly magnetic after cold working. |

| Tensile Strength | 515-620 MPa. | 540-750 MPa. |

| Yield Strength | 205 MPa. | 215 MPa. |

| Elongation | 40-70%. | 70%. |

| Density | 7.9 g/cm³. | 8.0 g/cm³. |

| Melting Point | 1400-1450°C. | 1400-1455°C. |

| Applications | Kitchenware, food processing, and automotive parts. | Kitchenware, medical tools, food processing. |

| Advantages | Affordable, durable, versatile. | Higher strength, better corrosion resistance. |

| Disadvantages | Limited chloride resistance, lower strength. | Susceptible to chloride pitting, more expensive. |

Key Chemical Composition Differences

In the context of 18-8 stainless steel and 304 stainless steel, 304 is one of the varieties of 18-8 stainless steel. The designation ‘18-8’ stands for stainless steels which contain approximately 18% chromium and 8% nickel, but that ‘18-8’ is more like a broad category, whereas 304 stainless steel is defined more by specific industry standards.

18-8 Stainless Steel

- Chromium Content: ~18-20%

- Nickel Content: ~8-10.5%

- Stainless steel 18-8 may also contain small amounts of other elements, such as manganese (up to 2%) and trace amounts of carbon (less than 0.08%), phosphorus, and sulfur.

- Because of its moderate corrosion resistance coupled with good formability, it finds numerous general-purpose applications.

304 Stainless Steel

- Chromium Content: 18-20%

- Nickel Content: 8-10.5%

- Carbon Content: ≤ 0.08%

- Manganese Content: ≤ 2%

- It also adheres to the ASTM and SAE standards for stainless steels, which are known to impose stricter limits on impurities and the overall quality of the steel. 18-8 stainless steel tends to be more inconsistent in performance.

Differences of Interest

Even though 18-8 and 304‘s compositions overlap substantially, 304 stainless steel has greater assurance of quality, because it is more reliable in terms of standards and is bound by regulations. This differentiation is significant in withstanding more stringent tolerances, as in medical devices, food-grade devices, aerospace parts, and similar areas where performance or safety risks due to material property shifts are possible.

Performance in Corrosive Environments

Both 18-8 and 304 stainless steels demonstrate excellent corrosion resistance, making them highly suitable for various applications exposed to moisture, chemicals, and other corrosive agents. However, 304 stainless steel has a slight advantage in more stringent environments due to its tighter compositional control. Below are five notable examples showcasing their performance in corrosive environments:

- Marine Environments

- 304 stainless steel resists general corrosion from saltwater exposure, whereas 18-8 may experience minor pitting in prolonged contact with highly saline conditions. Regular maintenance enhances durability for both.

- Chemical Processing

- 304 performs better when exposed to acidic compounds such as sulfuric acid, often used in industrial cleaning solutions, where precision-grade resistance is required.

- Food Processing

Both grades resist corrosion caused by exposure to acidic foods, such as citrus fruits and tomatoes. However, 304’s consistent quality ensures compliance with stricter food safety standards.

- High Humidity

Both steels effectively resist rust formation under high-humidity conditions. 304’s superior consistency minimizes the risks of localized corrosion, even in long-term exposure.

- Industrial Environments

- 304 stainless steel withstands harsh industrial chemicals, such as chlorides, better than generic 18-8 stainless, making it more reliable in areas that experience exposure to corrosive substances or processes.

These distinctions underscore why 304 stainless steel is often preferred for environments demanding higher precision and durability.

Considerations for Fasteners and Industrial Use

When choosing fasteners for industrial purposes, I concentrate on materials that provide an adequate balance between strength, corrosion resistance, and dependability for the given environment. For such stringent tasks, I use 304 stainless steel because it is everlastingly sturdy and much more resistant to chemicals and moisture than standard alternatives. This guarantees sustained effectiveness, maintenance-free, and in harsh industrial settings.

Understanding the 300 Series of Stainless Steel

The 300 series stainless steel encompasses a family of austenitic stainless steels, 304 and 316, with chlorides being the most corrosive to the 316 grade. The austenitic steels are noted for their industrial versatility. 316 is also employed in marine applications due to its strength and resistance against highly corrosive environments. Most steels and alloys are nonmagnetic, easy to weld, and have commercial applications in construction, food processing, and chemical manufacturing.

What is the 300 Series?

314 and 316 are referred to as the 300 series and are noted for versatile applications in construction, chemical processing. Additionally, these steels also perform well in marine environments.

Role of Nickel and Chromium in the 300 Series

| Element | Role |

|---|---|

| Nickel | Enhances corrosion resistance and toughness. |

| Stabilizes austenitic structure for ductility. | |

| Improves weldability and high-temperature strength. | |

| Reduces brittleness at low temperatures. | |

| Chromium | Forms a protective anti-corrosion oxide layer. |

| Increases resistance to oxidation and chemical attacks. | |

| Provides hardness and durability. | |

| Essential for stainless steel’s “stainless” property. |

Why It’s Widely Used Across Industries

Both 18-8 and 304 stainless steels are highly resistant to corrosion, which makes them ideal for use in applications that come into contact with water, chemicals, or other corrosive materials. However, 304 stainless steel is marginally better in more stringent environments owing to its composition. The following are five notable examples illustrating their performance in corrosive environments:

- Marine Environments

Concerning general corrosion caused by saltwater, 304 stainless steel offers more resistance than 18-8, which suffers from some pitting in salt-laden environments. Both grades benefit from regular maintenance.

- Chemical Processing

In the presence of sulfuric acid, commonly used in industrial cleaning solutions, 304 outperforms due to the required precision-grade resistance.

- Food Processing

Both grades are corrosion-resistant from exposure to acidic foods, such as citrus fruits and tomatoes. However, 304’s consistent performance guarantees compliance with strict food safety regulations.

- High Humidity

Both steels effectively resist rust formation under high-humidity conditions, but 304’s better consistency lowers the chances of localized corrosion risk during long-term exposure.

- Industrial Environments

Compared to 18-8 stainless, 304 stainless steel is more reliable in locations where harsh industrial chemicals like chlorides are used, as it withstands exposure to corrosive substances and processes better.

These differences highlight why 304 stainless steel is the most sought-after metal for work in more precise and durable environments.

Why Choose 316 Stainless Steel?

316 stainless steel is very corrosion-resistant, making it an excellent option for saltwater applications. It is also strong and durable, making it ideal for marine, industrial, or medical applications. Adding molybdenum significantly improves the impression of crevice and pitting corrosion resistance, assuring long-term performance in extreme conditions. For these reasons, 316 stainless steel can be considered a reliable and high-quality material for many demanding purposes.

Benefits of Over 304 Stainless Steel

| Grade | Benefit Over 304 |

|---|---|

| 316 | Superior corrosion resistance in chlorides and acids. |

| Enhanced durability in marine environments. | |

| Better resistance to pitting and crevice corrosion. | |

| 301 | Higher tensile strength and fatigue resistance. |

| 430 | Lower cost, suitable for mild environments. |

| 316L | Improved weldability and reduced carbon content. |

| 317 | Better resistance to chemical corrosion. |

Enhanced Corrosion Resistance with Molybdenum

Adding molybdenum to 316 stainless steel greatly improves corrosion resistance relative to 304 stainless steel. Molybdenum strengthens the alloy’s resistance to pitting and crevice corrosion, particularly in chloride-saturated solutions. For this reason, 316 stainless steel is ideal for use in coastal areas, chemical processing plants, and places where seawater or de-icing salts are frequently encountered.

Research shows that 316 stainless steel comprises roughly 2-3% molybdenum, accounting for the alloy’s high resistance to harsh chemical agents such as sulfuric acid and hypochlorite. For example, the Pitting Resistance Equivalent Number (PREN), which measures localized corrosion resistance, is around 22-28 for 316 stainless steel and 18-20 for 304 stainless steel. This value indicates the relative performance of the alloy in severe environments.

Moreover, molybdenum lowers the chances of stress corrosion cracking at elevated temperatures and high pressures, thus increasing the material’s dependability in harsh industrial settings. These characteristics make 316 stainless steel the material of choice for harsh marine industrial applications, heat exchangers, and long-lasting medical implants, where enduring strength is critical.

Applications in Marine and Chemical Industries

316 stainless steel is very well known in the marine and chemical industries due to its exceptional resistance to corrosion, durability, and strength. Provided below are five specific uses highlighting how this alloy is used in these industries:

- Marine Equipment: Due to the alloy’s high resistance to saltwater pitting, it is extensively used in fabricating ship accessories, propeller shafts, and underwater pipelines.

- Storage Tanks: Used in chemical processing units, tanks of 316 stainless steel store corrosive liquids like acids and chlorides safely.

- Heat Exchangers: 316 stainless steel is an excellent material for heat exchanger parts because it can withstand high temperatures and corrosive fluids in marine and chemical applications.

- Desalination Plants: Components such as pumps, valves, and piping within the plant need 316 steel because it can endure the highly corrosive saltwater environment.

- Industrial Reactors: It can resist stress corrosion, cracking, and chemical degradation, making it safe for long-term use in reactors that handle highly reactive chemicals.

Marine and chemical industries need extreme materials like 316 stainless steel and its alloys to endure harsh working environments, and this material can provide these.

References

- Effect of temperature on the notch sensitivity of a class 303, 18-8 austenitic stainless steel – A study on the temperature effects on 18-8 stainless steel’s properties.

- The effect of the cold rolling on the structure and mechanical properties in austenitic stainless steels type 18-8 – Research on how cold rolling impacts the structure and mechanical properties of 18-8 stainless steel.

- AT VARIOUS TEMPERATURES – A paper discussing the behavior of 18-8 stainless steel under explosive loads and temperature variations.

Frequently Asked Questions (FAQ)

Q: What is the main difference between 18-8 stainless steel and 304 stainless steel?

A: The main difference between 18-8 stainless steel and 304 stainless steel lies in their composition. Both are austenitic stainless steels, but 304 stainless steel typically has a higher nickel content, which enhances its corrosion resistance and improves its overall durability.

Q: How does the chromium and nickel content affect 18-8 grade stainless steel?

A: The chromium and nickel content in 18-8 grade stainless steel provides excellent resistance to corrosion and gives it non-magnetic properties. The typical composition includes 18% chromium and 8% nickel, which helps maintain its strength and durability.

Q: Can 18-8 stainless steel and 304 stainless steel be used in food processing applications?

A: Yes, 18-8 stainless steel and 304 stainless steel are commonly used in food processing due to their resistance to corrosion and ease of cleaning. 304 stainless steel is particularly preferred because of its superior resistance to pitting from chloride solutions.

Q: Are 18-8 stainless steel sheets suitable for automotive applications?

A: Yes, 18-8 stainless steel sheets are often used in automotive applications due to their excellent resistance to corrosion and good tensile strength. They are ideal for durable parts and resistant to environmental factors.

Q: What are the magnetic properties of 304 stainless steel?

A: 304 stainless steel is generally considered non-magnetic in its annealed state. However, it can exhibit some magnetic properties when cold-working, as the austenitic structure may be partially transformed to martensite.

Q: How does cold working affect the properties of 18-8 and 304 stainless steel?

A: Cold working can increase the tensile strength and hardness of 18-8 and 304 stainless steel but may also induce slight magnetic properties. It also enhances their ability to withstand mechanical stress, making them suitable for various industrial applications.

Q: Why is 304 stainless steel considered a popular type of stainless steel?

A: 304 stainless steel is popular due to its versatility, excellent resistance to corrosion, and ease of fabrication. Its balance of chromium and nickel content provides a great combination of mechanical properties and resistance to environmental factors, making it suitable for a wide range of applications.

Q: What is the role of the American Iron and Steel Institute in defining stainless steel grades?

A: The American Iron and Steel Institute (AISI) plays a crucial role in standardizing the composition and properties of different stainless steel grades. This ensures consistency and reliability in the materials used across various industries, including the 18-8 and 304 stainless steel classifications.

Q: How do 18-8 stainless steel fasteners compare to those made from 304 stainless steel?

A: 18-8 stainless steel fasteners are similar to those made from 304 stainless steel, as they share the same basic composition. However, 304 fasteners typically have a slightly higher nickel content, providing enhanced resistance to corrosion, making them preferable in more demanding environments.

Q: What should be considered when choosing between 18-8 vs 304 stainless steel for specific applications?

A: When choosing between 18-8 vs 304 stainless steel, consider the specific environmental conditions, such as exposure to chlorides, required mechanical properties, and potential for magnetic properties. 304 stainless steel is often preferred for its superior resistance to corrosion and better performance in chloride-rich environments.