Knowing the key differences between alloys is essential when selecting the best stainless steel for any application. 304 stainless steel and 409 stainless steel are the most commonly available for comparison, each presenting different properties and benefits. Depending upon whether you are designing for performance, looks, or cost, selecting the correct material will have a significant effect on the results and its life span. An in-depth article compares 304 stainless steel and 409 stainless steel based on their composition, properties, advantages, disadvantages, and other factors. After reading, you will know which stainless steel grade fits your application best and why.

Introduction to Stainless Steel Grades

Stainless steel varieties mean stainless steel classification according to their composition, properties, or use. 304 and 409 constitute two common types of stainless steel. Gr. 304 is famous for being highly corrosion-resistant, versatile, and durable; thus, it finds uses in kitchenware, surgical instruments, and architectural works. Meanwhile, gr. 409 steels are appreciated for their cheapness and heat resistance while employed for automobile exhausts and other environments where a little corrosion resistance is acceptable. This knowledge of grades will let you choose the right stainless steel for your needs.

What are Stainless Steel Grades?

Based on stainless steel types and their composition, depending on their mechanical properties, criteria are developed to establish their suitability in a given application, be it via strength, corrosion resistance, or heat tolerance.

Importance of Choosing the Right Grade

Choosing the proper stainless steel grade is essential for better performance, longevity, and safety in varying applications. Factors influencing the choice include the environment in which the material has to operate, strength requirements, resistance to corrosion, heat, or wear.

Corrosion Resistance

Good corrosion resistance makes the 304 and 316 stainless steel grades widely used. Grade 316 is also referred to as “marine grade.” The grade contains molybdenum that imparts high chloride resistance, enabling its use in coastal locations or chemical industries. According to recent reports, Grade 316 stainless steel contains 2% to 3% molybdenum in the composition, imparting about 20% improved chloride resistance than Grade 304 stainless steel.

Strength and Durability

Duplex stainless steels, such as Grade 2205, are often favored in applications that require special strength requirements. These materials have ductility comparable to austenitic stainless steel but twice as strong as the ferritic grades, thus favoring duplex stainless steels for structural members of bridges or storage tanks.

Heat Resistance

For high-temperature applications, 310 and 309 grades are well known for their heat resistance. Thus, they retain strength and resistance to oxidation at temperatures beyond 1,800°F (980°C). For instance, grade 310 is used widely in furnace components whenever heat resistance is required.

Cost Considerations

Choosing the proper grade also impacts cost-efficiency over time. For instance, a stainless steel grade such as 316 might incur higher upfront costs, yet enhanced durability and resistance to corrosion will diminish maintenance and replacement costs. Studies show that using a grade unsuited to the environment can increase maintenance to 40%.

Global consumption insights

Market data recently suggests that austenitic grades like 304 and 316 comprise about 70% of stainless steel production worldwide due to all-around performance and moderate cost. Also, duplex grades are becoming increasingly popular, with a 6% estimated growth rate annually, which is induced by demand from oil and gas, among other industries.

Hence, by precisely analyzing situations considering environmental factors, mechanical properties, and lifecycle costs, industries guarantee that, having chosen the correct stainless steel grade, performance will be better, and less money will be spent. At the same time, the solution stands the test of time.

Overview of 304 and 409 Stainless Steel

| Parameter | 304 Stainless Steel | 409 Stainless Steel |

|---|---|---|

| Chromium Content | 18-20% | 10.5-11.75% |

| Nickel Content | 8-10.5% | None |

| Corrosion Resistance | Excellent | Moderate |

| Heat Resistance | Good | Better |

| Magnetic Property | Non-magnetic (annealed) | Magnetic |

| Tensile Strength | 505 MPa | 450 MPa |

| Yield Strength | 215 MPa | 240 MPa |

| Elongation | 40% | 20% |

| Density (g/cm³) | 7.93 | 7.75 |

| Melting Point (°C) | 1400-1450 | 1425-1510 |

| Thermal Conductivity | 16.2 W/m·K | 24 W/m·K |

| Cost | Higher | Lower |

| Applications | Food, medical, chemical, and architecture | Automotive exhaust, heat exchangers |

| Durability | Long-lasting | Moderate lifespan |

| Ease of Welding | Moderate | Easier |

Key Characteristics of 304 Stainless Steel

Known practically worldwide for its corrosion resistance, durability, and versatility, 304 stainless steel finds usage in a variety of applications that call for resistance to oxidizing environments: for instance, kitchen equipment, chemical containers, and architectural structures. This type of stainless steel is highly formable, meaning it is easily shaped and welded. Besides, it retains strength and performance in diverse temperatures, from low to high temperatures. The stainless steel owes its high resistance to rust and staining to being chromium-nickel.

Chemical Composition of SS 304

The chemical composition of SS 304 usually contains 18-20% chromium, 8-10.5% nickel, up to 2% manganese, not more than 0.08% carbon, and a few traces of silicon, phosphorus, and sulfur, thereby imparting good corrosion resistance and durability.

Physical Properties of 304 Stainless Steel

The 304 stainless steel has various physical properties, making it highly versatile in and beyond applications across industries. Below are some chief properties of 304 stainless steel:

- Density

7.93 g/cm³ (7930 kg/m³)

- Melting Point

Approximately 1400°C to 1450°C (2552°F to 2642°F)

- Thermal Conductivity

16.2 W/m·K (at 100°C or 212°F)

- Modulus of Elasticity

193-200 GPa (28-29 × 10⁶ psi)

- Coefficient of Thermal Expansion

17.2 µm/m·K (from 0°C to 100°C or 32°F to 212°F)

These properties make SS 304 ideal in construction, automotive, kitchenware, etc., requiring strength, heat resistance, and durability.

Common Applications of 304 Stainless Steel

| Industry | Application |

|---|---|

| Automotive | Exhaust systems, structural supports |

| Food and Beverage | Storage tanks, countertops, sinks |

| Medical | Surgical tools, implants |

| Chemical Processing | Heat exchangers, piping, storage tanks |

| Construction | Railings, cladding, decorative panels |

| Kitchenware | Cookware, utensils, cutlery |

| Marine | Boat fittings, marine hardware |

| Consumer Goods | Appliances, hardware, fasteners |

| Architectural | Building facades, sculptures |

| Energy | Solar panel frames, power generation |

Key Characteristics of 409 Stainless Steel

- Corrosion Resistance

It offers good resistance to corrosion in mildly corrosive atmospheres, and hence, it finds applications in automotive exhaust systems and allied fields.

- High Temperature Strength

Maintains its structural integrity at elevated temperatures and stays physically strong in thermal environments.

- Economical

Often cheaper compared to other grades of stainless steel due to low chromium content.

- Weldability

Being good in weldability, it eases the making and fabrication process.

- Oxidation Resistance

Keep oxidation and scaling at bay till 675ºC (1247ºF) environments.

With these attributes, 409 stainless steel is in good stead, mainly when retarding heat and cost is required in applications in the auto and industrial sectors.

Chemical Composition of SS 409

The chemical composition of SS 409 stainless steel has been optimized for excellent corrosion and oxidation resistance at a low cost. Typical elements (in weight percentage) and their respective ranges used in SS 409 are given below:

| Element | Composition (%) | Function |

|---|---|---|

| Chromium (Cr) | 10.50–11.75 | Enhances corrosion and oxidation resistance. Essential for stainless steel formation. |

| Nickel (Ni) | 0.50 max | Improves toughness and slightly enhances corrosion resistance. |

| Carbon (C) | 0.03–0.08 | Kept low to improve weldability and avoid carbide precipitation. |

| Manganese (Mn) | 1.00 max | Adds strength and improves hot working properties. |

| Silicon (Si) | 1.00 max | Enhances oxidation resistance and provides additional strength. |

| Phosphorus (P) | 0.040 max | Controlled to avoid brittleness and maintain ductility. |

| Sulfur (S) | 0.020 max | Minimizing sulfur content improves corrosion resistance. |

| Titanium (Ti) | 6x(C+N) min, 0.50 max | Stabilizes the microstructure by binding with carbon and nitrogen, reducing the risk of intergranular corrosion. |

| Nitrogen (N) | 0.030 max | Kept low to avoid detrimental effects on weldability and toughness. |

| Iron (Fe) | Balance | Forms the base of the alloy. |

Key Notes on SS 409 Composition

- The presence of the element titanium is considerably desirable because it helps resist intergranular corrosion while maintaining strength at elevated temperatures.

- SS 409 uses less chromium than many other steels, but it is effective enough to protect against oxidation and corrosion in hostile atmospheres.

- Due to its extremely low carbon content, it exhibits excellent weldability, which is crucial in the automotive, construction, and industrial sectors.

This chemical balance lends to SS 409’s fame as a dependable heat-resistant stainless steel suited for applications that need moderate corrosion resistance on a budget.

Physical Properties of 409 Stainless Steel

Since the physical properties of stainless steel make 409 very versatile for numerous uses, one can consider these aspects:

- Density: It is about 7.7 g/cm³ or 0.278 lb/in³, which goes towards its structural stability and durability.

- Melting Point: Ranges between 1420°C and 1510°C (2588°F to 2750°F), showing very good heat resistance.

- Thermal Conductivity: 23.9 W/m·K at 100°C, enabling it to conduct heat in high-temperature conditions successfully.

- Specific Heat Capacity: 460 J/kg·K, thus highlighting its heat absorption and retention capability.

- Elastic Modulus: 200 GPa, giving it high strength but enough flexibility to allow fabrication.

These physical properties make SS 409 a good material for applications that require a low-cost, sturdy material with moderate corrosion and heat resistance.

Common Applications of 409 Stainless Steel

| Industry | Application |

|---|---|

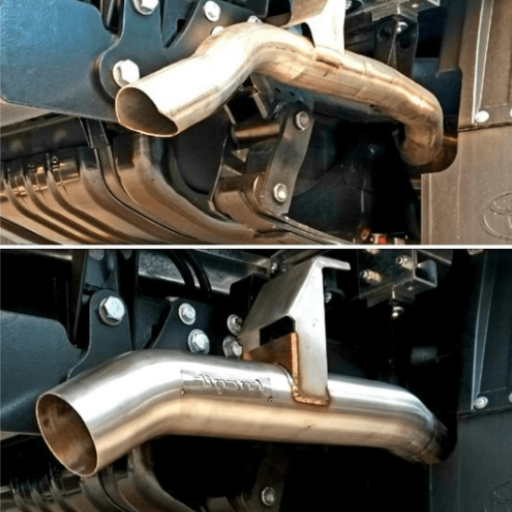

| Automotive | Exhaust systems, mufflers, catalytic converters |

| Agriculture | Equipment panels, protective components |

| Construction | Structural supports, reinforcements |

| Industrial | Heat exchangers, furnace parts |

| Energy | Power plant components, thermal systems |

| Marine | Non-critical fittings, lower-salt environments |

| Transportation | Train parts, undercarriage components |

| Appliance Manufacturing | Heating elements, economical hardware |

| Public Infrastructure | HVAC systems, exhaust ducts |

| Mining | Screening and crushing equipment |

Comparing 304 vs 409 Stainless Steel

| Parameter | 304 Stainless Steel | 409 Stainless Steel |

|---|---|---|

| Chromium Content | 18-20% | 10.5-11.75% |

| Nickel Content | 8-10.5% | None |

| Corrosion Resistance | Excellent | Moderate |

| Heat Resistance | Good | Better |

| Magnetic Property | Non-magnetic (annealed) | Magnetic |

| Tensile Strength | 505 MPa | 450 MPa |

| Yield Strength | 215 MPa | 240 MPa |

| Elongation | 40% | 20% |

| Density (g/cm³) | 7.93 | 7.75 |

| Melting Point (°C) | 1400-1450 | 1425-1510 |

| Thermal Conductivity | 16.2 W/m·K | 24 W/m·K |

| Weldability | Moderate | Easier |

| Durability | Long-lasting | Moderate lifespan |

| Cost | Higher | Lower |

| Common Applications | Food, medical, architectural uses | Automotive exhaust, heat exchangers |

Difference Between 304 and 409 Stainless Steel

| Parameter | 304 Stainless Steel | 409 Stainless Steel |

|---|---|---|

| Chromium Content | 18-20% | 10.5-11.75% |

| Nickel Content | 8-10.5% | None |

| Corrosion Resistance | Excellent | Moderate |

| Heat Resistance | Good | Better |

| Magnetic Property | Non-magnetic (annealed) | Magnetic |

| Tensile Strength | 505 MPa | 450 MPa |

| Yield Strength | 215 MPa | 240 MPa |

| Elongation | 40% | 20% |

| Density (g/cm³) | 7.93 | 7.75 |

| Melting Point (°C) | 1400-1450 | 1425-1510 |

| Thermal Conductivity | 16.2 W/m·K | 24 W/m·K |

| Weldability | Moderate | Easier |

| Durability | Long-lasting | Moderate lifespan |

| Cost | Higher | Lower |

| Common Applications | Food, medical, architectural uses | Automotive exhaust, heating systems |

Pros and Cons of 409 Stainless Steel

Advantages of 409 Stainless Steel

- Cost-Effective

409 stainless steel is much more affordable than other stainless steel grades, giving it an edge over other stainless steels when an application requires budget considerations.

Cost Comparison: Lower cost when compared with a 304 stainless steel grade.

- High Thermal Conductivity

Its thermal conductivity is 24 W/m·K, which is better than that of a 304-grade material and makes it suitable for applications like heat-sensitive automotive exhaust systems.

- Corrosion Resistance to a Certain Degree

It does not match corrosion resistance relative to 304, but it performs well in environments where exposure to exhaust gases or moderate moisture levels might occur.

- Weldability

Easier welding means less time to produce, thus reducing costs, especially in the automotive or manufacturing industries.

- Heat Durability

Given its moderate strength and resistance to heat, it is used in high-temperature operations like heat exchangers and mufflers.

Disadvantages of 409 Stainless Steel

- Lower Corrosion Resistance

Less resistance to rust and staining than stainless steel 304 limits its use in corrosive environment applications.

- Lower Mechanical Strength

The yield strength of 240 MPa is somewhat inferior to that of some counterparts, possibly affecting performance in high-stress conditions.

- Not Aesthetically Pleasing

The preference for 409 will be less for applications requiring a polished or decorative finish due to the oxide layer that they develop, which eventually causes discoloration.

- Shorter Life in Harsher Environments

Compared to 304, it presents only moderate life expectancy under aggressive environmental exposures such as saltwater or acidic media.

- Less Versatile

It is restricted to very few applications, such as automotive exhaust systems and heat exchangers, and does not have the versatility of higher-grade stainless steels.

Pros and Cons of 304 Stainless Steel

Pros

- The High Corrosion Resistance

- 304 stainless steel has a high resistance to rust and corrosion, and this makes 304 stainless steel perfectly suitable for use in environments where moisture or chemical contact occurs.

Data point: It does well in environments with a chloride concentration of up to 200 ppm.

- The Excellent Durability

- It is strong and can resist wear and tear, making 304 suitable for industrial and domestic applications.

- Data point: Tensile strength approximately 505 MPa maintains the integrity of a structure under severe conditions.

- Highly Versatile

- 304 stainless steel is also suitable for various applications due to its fairly balanced composition: kitchen appliances, piping, construction materials, etc.

- Data Point: Popularly applied in nearly 50% of industries of stainless steel manufacture worldwide.

- Vista

- Its glossy finish retains its shine and is easy to maintain, making it suitable for applications where aesthetics are necessary.

- Data Point: After polishing, its finish is almost mirror-like, with surface roughness less than 0.8 µm.

- Good Heat Resistance

- 304 is intended to retain its structural properties at high temperatures; it finds use in heat exchangers and cooking equipment.

- Data Point: Able to resist high temperature up to 870°C in intermittent service.

Cons

- Costly

- Higher-grade steel, such as 304, is costlier than cheaper alternatives like 409, and a budget-sensitive project may not be able to justify its use.

- Stress Corrosion Cracking Potential

- Under severe chloride and tensile loading conditions, 304 may be vulnerable to stress-related cracking.

- Non-Magnetic Nature

- While this may be advantageous in some cases, its non-magnetic nature could be a drawback for industries that depend on magnetic detection systems.

- Lower Hardness in the Untreated State

- Though naturally tough, 304 may not withstand applications requiring hardening treatments for harder metals if it remains unhardened.

- Little Resistance Against Chloride Exposure

- In some chloride-rich environments where prolonged exposure occurs, it is known to suffer from pitting or crevice corrosion.

By comparing these pros and cons in detail, one can determine whether the 304 suits their project requirements.

Conclusion: Choosing Between 304 and 409 Stainless Steel

| Parameter | 304 Stainless Steel | 409 Stainless Steel |

|---|---|---|

| Suitability | Best for corrosion-resistant environments | Ideal for high-heat applications |

| Cost | Higher | Lower |

| Durability | Longer lifespan | Moderate lifespan |

| Maintenance | Low-maintenance | Moderate maintenance required |

| Magnetic Property | Non-magnetic (annealed) | Magnetic |

| Common Applications | Medical, food processing, architecture | Automotive exhaust, heating systems |

| Heat Resistance | Good for moderate heat | Better for high-temperature systems |

| Corrosion Resistance | Excellent | Moderate |

| Recommended Use | Premium, heavy-duty applications | Cost-efficient, moderate-duty uses |

Factors to Consider When Choosing

The choice between 304 and 409 grades of stainless steel can be based on project requirements. Whenever corrosion resistance and beautiful allure are prioritized, I favor 304 stainless steel because of its excellent protection and fine finish. In contrast, 409 stainless steel may be preferred for relatively inexpensive projects demanding good durability while residing in moderately less corrosive environments. After weighing all cost factors against exposure to the environment and functional lifetime, I am thus able to pick one to fulfill my purpose.

Final Recommendations

Upon checking the options, I would opt for 304 stainless steel if the project is geared toward needing high corrosion resistance, high aesthetics, and utmost durability. However, 409 stainless steel remains the way to go if cheap, with adequate performance in less corrosive environments, is enough. I tend to sway from balancing the project’s expenses versus its environmental requirements.

Future Trends in Stainless Steel Usage

The stainless steel sector is charting a path toward tremendous growth, led by demand for sustainable materials and the potential for advanced industrial applications. According to a recent market study, the global stainless steel market size is projected to grow at a whopping CAGR of around 5.8% between 2023 and 2030, propelled by the construction, automotive, and renewable energy sectors.

One possible emerging trend is the growing use of stainless steel for green energy solutions. For example, stainless steel plays a vital role in wind turbine manufacture, as its strength and corrosion resistance are necessary for the turbines to tackle adverse environmental conditions. Additionally, solar power infrastructure currently employs stainless steel for its sustainability strategy, with a view toward durability and low maintenance.

The use of stainless steel in EV manufacturing has also become more prominent. EV manufacturers increasingly prefer stainless steel for battery enclosures, vehicle frames, and other applications because it is lightweight, recyclable, and resilient. By way of example, Tesla’s significant introduction of stainless steel with its Cybertruck has firmly ushered the metal into the automotive fold.

Urbanization and an emphasis on green architecture have further fuelled demand for stainless steel in construction. Combining aesthetic appeal, full recyclability, and unsurpassed durability, stainless steel is becoming the material of choice for building façades, bridges, and interior design.

These advances characterize stainless steel as a sustainable material used by global trends involving decarbonization and minimizing material waste. Advancements in the design of stainless alloys and manufacturing methods will thus enhance its applications, making stainless even more versatile in the coming years.

References

- High-Temperature Characteristics of Stainless Steel

Stanford University – PDF Document

This document discusses the high-temperature characteristics of stainless steel, including Type 409. - Stainless Steel Grade Chart

Stanford University – PDF Document

Provides a detailed comparison of stainless steel grades, including 304 and 409, focusing on corrosion resistance and applications. - Material Overview – ANSI Standards

Purdue University – PDF Document

This article offers an overview of stainless steel grades, including 304 and 409, focusing on their properties and standards.

Frequently Asked Questions (FAQ)

What are the main differences between 304 and 409 stainless steel?

The primary difference between 304 and 409 stainless steel is their composition and properties. 304 grade stainless steel is an austenitic stainless steel with higher percentages of chromium and nickel, providing excellent corrosion resistance. In contrast, 409 stainless steel is a ferritic stainless steel that offers moderate corrosion resistance and is commonly used in automotive exhaust systems due to its lower cost and decent performance in exhaust applications.

Is 304 stainless steel better for exhaust systems than 409?

304 stainless steel is generally considered better for high-performance exhaust systems due to its superior corrosion resistance and durability at higher temperatures compared to 409 stainless steel. While 409 stainless steel is often used for budget-friendly exhaust parts, 304 provides a longer lifespan and better overall quality in harsh automotive conditions.

What type of stainless steel is commonly used for exhaust?

Both 304 and 409 stainless steels are commonly used in automotive exhaust systems. 304 is favored for high-performance applications where corrosion resistance is crucial, while 409 is typically used in lower-cost exhaust systems where budget constraints are a priority. Understanding the differences in properties helps select the appropriate stainless steel for specific exhaust needs.

How does the corrosion resistance of 304 grade stainless steel compare to 409?

Due to its higher nickel content and chromium percentage, 304-grade stainless steel exhibits significantly better corrosion resistance than 409-grade stainless steel. This makes 304 a preferred choice in environments where exposure to moisture and corrosive elements is common, while 409 may develop surface rust more quickly under similar conditions.

Can 409 stainless steel be used for automotive exhaust?

Yes, 409 stainless steel can be used for automotive exhaust systems. It is commonly utilized for exhaust parts because it is cost-effective and provides adequate performance for standard applications. However, for high-performance vehicles that require maximum durability and resistance to corrosion, 304 stainless steel is often recommended.

What are the typical applications of 304 grade stainless steel in exhaust systems?

304-grade stainless steel is typically used in high-performance exhaust systems, exhaust tips, and components that require excellent corrosion resistance. Its ability to withstand higher temperatures makes it suitable for applications in automotive and industrial exhaust systems, where longevity and performance are critical.

How does the nickel content affect the properties of 304 and 409 stainless steel?

The nickel content plays a significant role in determining the properties of stainless steel. 304 stainless steel contains a higher percentage of nickel, which enhances its corrosion resistance and makes it more suitable for harsh environments. Conversely, 409 stainless steel has a lower nickel content, reducing corrosion resistance but making it a more cost-effective solution for exhaust applications.

What should I consider when choosing between 304 or 409 stainless steel for exhaust?

When choosing between 304 and 409 stainless steel for exhaust, consider budget, expected lifespan, and environmental conditions. If cost is a significant factor and the exhaust will not be exposed to extreme conditions, 409 may be suitable. However, for optimal performance, durability, and corrosion resistance, 304 grade stainless steel is the preferred option.