Stainless steel is a popular material in many industries because of its strength and resistance to damage. Grade 308 stainless steel has a noteworthy place due to its balanced composition and specialized properties. This post discusses comprehensively 308 stainless steel, its distinct features, how it differs from other grades, and the outstanding places it is used in. In this article, readers will learn the reasons behind the use of 308 stainless steel in welding, construction, and manufacturing, and how it makes this grade of stainless steel ideal for such applications. Readers, after going through this post, will learn how 308 stainless steel aligns with their needs and understand the reason behind its wide applications.

What is 308 Stainless Steel?

308 stainless steel is mainly composed of iron, chromium, and nickel, which makes it an Austenitic stainless steel. Like other alloys, 308 stainless steel has excellent resistance to corrosion, high strength, durability, and can withstand harsh conditions and high temperatures. Oxidation is not favorable under welding, and this type of stainless steel can withstand oxidation and maintain its strength, making 308 stainless steel suitable for industrial tools, construction materials, chemical processing, and various other applications. This enables stainless steel 308 to be versatile across many industries.

Overview of 308 Stainless

308 stainless steel is an austensitic alloy of chromium and nickel. Moreover, its corrosion resistance and mechanical strength set it apart from others. In extreme environments, 308 stainless steel maintains its strength and durability under high temperatures and high pressure. 308 stainless steel ensures long-term usability and low maintenance cost under harsh and hostile conditions due to its oxidation resistance.

Due to low cracking or warping, compatibilty with dissimilar metals, and excellent welding properties, this alloy is fights for food processing tools and equipment, construction structural elements, and industrial food handling equipment. The versatility coupled with reliability from diverse industrial applications makes 308 stainless steel the most preferred choice in engineering and fabrication projects.

Chemical Composition of 308 Stainless Steel

The primary ingredients of 308 stainless steel consist of approximately 19-21% chromium and 9-11% nickel, making it strong and resistant to corrosion. It also includes lesser amounts of carbon (up to 0.08%), silicon (up to 1%), and manganese (up to 2%), which enhances the overall performance and contributes to its weldability. Moreover, Sydney Steel maintains low levels of trace elements such as sulfur and phosphorus to retain the material’s strength. This exact blend of chemicals enables 308 stainless steel to withstand high temperatures and corrosive environments while maintaining durability and resistance.

Applications of 308 Stainless

Thanks to its excellent versatility, strength, and corrosion resistance, 308 stainless steel is extensively used across various industries. Outlined below are some of its corresponding technical parameters and key applications:

- Welding Applications:

- As a filler material for welding stainless steels, particularly type 304 and 304L, it is one of the most widely used stainless steels.

- Best suited for use in high-temperature and highly corrosive environments.

- Melting Point Range: 2540 – 2630°F (1390 – 1440°C).

- Food Processing Equipment:

- Due to ease of cleaning and hygienic properties, it is ideal for piping, containers, and machinery as well.

- Operating Temperature Range: Up to 800°F (425°C) without losing corrosion resistance.

- Chemical and Petrochemical Industries:

- Used in piping, heat exchangers, and storage tanks for corrosive acids and alkalis.

- Corrosion Resistance Property: Good if the level of chlorides in the environment is less than 200 ppm.

- Automotive and Aerospace Components:

- Exhaust systems, manifolds, and other high-temperature applications.

- Tensile Strength (Minimum): 75 ksi (515 MPa).

- Yield Strength (Minimum): 30 ksi (205 MPa).

- Architectural and Structural Components:

- Used in decorative panels, roofing, and structural reinforcements owing to its pleasing aesthetics and remarkable strength.

- Thickness Range (for panels): 0.018–0.036 inches (0.46–0.91 mm).

These examples bridge the gap between different industries and show how 308 stainless steel can withstand versatile and harsh environments.

Due to its broad usefulness, enthusiasts and professionals alike will prefer it because of its range of functionalities.

How does 308 Stainless Steel Compare to 316 Stainless?

The main difference between 308 stainless steel and 316 stainless steel is their composition and corrosion resistance. Both are austenitic stainless steels but unlike 308, 316 contains molybdenum which increases its susceptibility to pitting and corrosion, especially in marine or chloride-rich environments. 308 contains better weldability and is used widely in welding 300-series stainless steels. The selection between 308 and 316 depends on specific needs such as required corrosion resistance and the working environment.

Differences in Mechanical Properties

The comparison of 308 and 316 stainless steel reveals a very useful set of characteristics that explains likely applications and usage for them.

- Tensile Strength: Tensile strength of both 308 and 316 stainless steel is high; however, 316 tends to exhibit slightly higher tensile strength in the range of 515–620 MPa (megapascals) compared to 308 stainless steel with approximately 515 MPa. This makes 316 more appropriate for more demanding mechanical stress applications.

- Yield Strength: Yield strength for 308 is roughly 205 MPa, while 316 offers a slightly better yield strength performance of around 240 MPa. Slight differences in yield strength figure when using steel in structures make an impact, particularly when looking at more weight-bearing constructions.

- Hardness (Brinell, HB): 308 stainless steel tends to hold Brinell hardness values around 170–220 HB. 316 stainless steel shows identical hardness values. Both materials retain most of their mechanical properties under other conditions due to their austenitic structure.

- Elongation (% in 50mm): Both grades provide adequate ductility, and while 308 shows elongation values around 40–50%, 316 exhibits identical ductility, ideal for forming processes.

- Thermal Expansion and Conductivity: It is possible that 316 has slightly lower thermal conductivity than 308 due to its alloy composition with both in the range of 14–17 W/(m·K).

The difference in each constituent’s mechanical property does make 316 stainless steel a lot more desirable in superior environmentally corrosive regions, such as chemical processing or marine areas, whereas 308 is frequently used for welding and general-purpose applications.

Comparison of Corrosion Resistance

316 stainless steel is noticeably more corrosion resistant than 308 stainless steel due to the higher molybdenum content in the former. This increase in molybdenum helps 316 stainless steel resist pitting and crevice corrosion in chloride-containing areas such as seawater. Marine, industrial, chemical, or other harsh environments are better suited to 316 stainless steel because of its specialized resistance when compared to general-purpose 308 stainless steel.

Choosing between 308 vs 316 Stainless Steel

For use in marine or industrial applications with corrosive environments, especially those where chlorides are prevalent, I would opt for 316 stainless steel over 308. Unlike 308, 316 has greater resistance to pitting and crevice corrosion due to its higher molybdenum content. On the other hand, 308 remains cost effective along with providing basic corrosion resistance which makes it great for general-purpose applications not subject to extreme conditions.

Technical Parameters:

- 308 Stainless Steel

- Chromium Content: 18–21%

- Nickel Content: 9–11%

- Molybdenum Content: None

- Corrosion Resistance: Adequate for general-purpose environments.

- 316 Stainless Steel

- Chromium Content: 16–18%

- Nickel Content: 10–14%

- Molybdenum Content: 2–3%

- Corrosion Resistance: Exceptional for chloride-rich and severe environments.

Considerations include specific operating conditions and budget. For difficult environments, 316 stainless steel is a smart investment for ensuring durability and longevity.

What are the Mechanical Properties of 308 Stainless Steel?

308 stainless steel possesses exceptional mechanical properties and moderate strength that allow it to withstand a tensile stress of 505 to 750 MPa. Further, it has a ductility with an elongation of around 40% in tensile testing, making it able to endure dynamic loads without cracking. 308 stainless steel has a yield strength of about 215 MPa, giving it reliable structural strength. These factors combined allow for flexibility without threatening structural integrity, and even better, retaining pliability under sub-zero temperatures. These characteristics, combined with enhanced corrosion resistance and weldability, make 308 stainless steel ideal for various applications.

Strength and Durability

308 stainless steel is well known due to its exceptional balance of strength and flexibility. It has a yield strength of about 215 MPa, which is combined with remarkable toughness, even in harsh environments and low temperatures. This toughness ensures that there is reliable performance under stress. Its ductility is highlighted further by an elongation of nearly 40 % in tensile tests. It is capable of withstanding dynamic loads, which reduces the chances of cracking. 308 stainless steel also boasts a remarkable corrosion resistance, which makes it appealing in applications requiring durability and prolonged service life in aggressive environments. This, along with high weldability, makes it the material of choice in construction, automotive, and food processing industries.

Ductility and Weldability

308 stainless steel as an alloy grade offers remarkable ductility, which is important for parts that undergo large plastic deformation without breaking. For such parts, the dynamic power absorption capability is very important, and thus, during tensile testing, its elongation is around ~40%. Its weldability is another strength due to low carbon content, which leads to reduced carbide precipitation during welding and less intergranular corrosion. Best results are obtained with TIG or MIG welding.

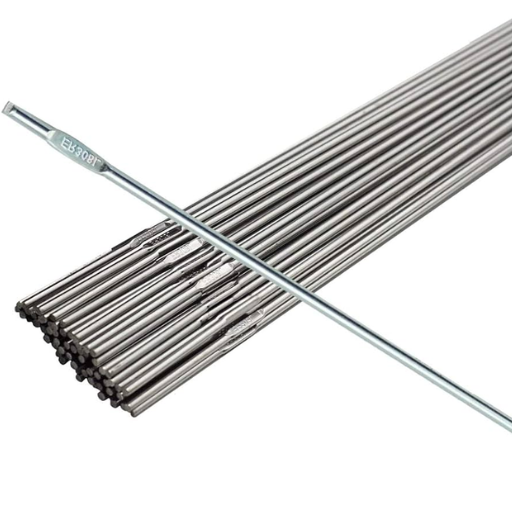

Versatility in applications with high-performance seamless requirements is attributed to the 311 stainless steel properties, like tensile strength of 308 stainless steel about 515 MPa (minimum) with yield strength at 205 MPa (minimum) , as well as a melting range of 2550°F–2650°F (1400°C–1450°C). Moreover, during welding, the use of filler materials such as ER308 or ER308L improves joint strength, corrosion resistance, and overall efficiency. Fulfilling the demands of arduous conditions can be achieved by proper pre-weld cleaning, precise heat control, and eliminating unnecessary heat input.

Impact of Nickel and Chromium

The addition of nickel and chromium increases the strength and corrosion resistance of stainless steel. Chromium creates a protective oxide layer that prevents oxygen and rust from penetrating the material, even under tough conditions. Nickel enhances ductility and toughness, as well as stabilizing the austenitic structure of the steel. This is important because the mechanical properties of the stainless steel need to be preserved at different temperatures. These elements together contribute to the renowned durable and versatile characteristics of stainless steel for industrial and architectural purposes.

Why is 308 Stainless Steel suitable for Welding Applications?

The welding applications for 308 stainless steel are numerous due to its corrosion resistance and mechanical properties. It is able to withstand high temperatures without losing structural integrity or strength, thus enabling welding of constituents in harsh conditions. Moreover, its composition helps prevent weld cracking and is compatible with a large number of stainless steels, thus ensuring dependable welds.

Role of MIG Wire in Welding

Welding wires increase the efficiency of welding by enabling two metals to be united at the center using a high-precision cutting tool. It is constantly fed into the welding gun and is heated to the point where it is melted, creating a powerful bond where the materials fuse. One of the most important aspects of wires is their type. Criteria such as the base metals being welded together, the protecting gas shielded about them while welding, and the position at which the welding is done all affect the selection of MIG wire.

When welding with 308 stainless steel, the MIG wire typically used is ER308 or ER308L. These wires ensure compatibility with stainless steels and high corrosion resistance, and with the “L” version, there is lower carbide precipitation. Recommended technical parameters for MIG welding with ER308/ER308L wire include the following:

- Shielding Gas: 98% of Argon and 2% of Oxygen or 90% of Helium, 7.5% of Argon-2.5% of CO2 for strong arc stability and adequate penetration.

- Welding Current: 100 – 200 Amperes, dependent on the wire thickness and material ductility and thickness.

- Voltage: 19 – 26 V.

- Wire Feed Rate: 250 – 500 inches per minute, might need to alter based on specific setup (you will need to modify this depending on manual or robotic welding configuration).

- Shutter Speed: 10 – 14 inches per minute based on the technique and joint configuration.

Administratively, the selection of active MIG wire, machining conditions, and parameters reflects the quality of welded construction, resulting in minimal mechanical imperfections and worn spots, strength, and cross-section durability of stainless steel constructions.

Welding Stainless Steel with Grade 308

Grade 308 stainless steel is readily available because of its adept corrosion resistance and weldability, making it apt for food processing equipment, chemical tanks, and architectural components. Following the best practices while working with this grade through welding ensures the best outcomes.

Welding Guidelines for Grade 308

- Welding Process: TIG or MIG welding is usually suggested for Grade 308 stainless steel.

- Shielding Gas: For MIG welding, a combination of 2% Oxygen and Argon (98%) or 90% Helium, 7.5% Argon, and 2.5% CO₂ promotes fuller penetration and stability of the arc during welding. In the case of TIG welding, pure Argon or a mixture of Argon and Helium guarantees clean welds.

- Current: For MIG welding: 120-250 A, depending on the material’s thickness and design of the joints. For TIG welding: 50-200 A (DCEN – Direct Current Electrode Negative).

- Voltage: For MIG welding: 18-30 V, changes with the speed of the wire feeder and thickness of the welding material.

- Wire Feed Speed:

- 275–550 inches per minute (MIG welding), which can be modified for ideal deposition rate.

- Travel Speed:

- Depends on the technique of the welder and configuration of the workpiece, 8-14 inches per minute.

Strategies to Consider With Welds of 308

- Dirt and Slag: Pre-Cleaning: A procedure step that involves cleaning the base material surface of oil, grease, and dirt contamination to reduce the porosity or inclusions contamination risks.

- Temperature Maintenance: Try to keep the interpass temperature lower than 350°F (175° C), as a higher temperature range can lead to loss of structural integrity due to the carbide precipitation.

- Freq. for Controlled Changes – Controlled Heat input: This must be followed to avoid Alters to mechanical changes like warping/curling on the base material and/or its metallurgical properties.

- S/W Reversion: Restoration of surface (via stainless wire brush or passivation) corrosion resistance is referred to as Post-Weld Cleaning.

In following these techniques, welders are likely to produce countless and quality enduring welds on 308 stainless steel while avoiding for defects.

Advantages of Using 308 LSI

In my experience, 308 LSI has excellent welding properties, along with consistent results, which make it a popular option for other stainless steel applications. Having low carbon content improves abrasion resistance due to less carbide precipitation, particularly in high temperature or wet environments. Also, 308 LSI enhances polish grade and better mechanical properties, which guarantee strength and sharpness on both structural and decorative works. This robustness allied to precision makes it one of the most practical materials in the hands of competent welders.

What are the Corrosion Resistance Properties of 308 Stainless Steel?

The 308 grade of stainless steel is exceptionally durable due to the chromium and nickel complex content, providing a strong protective oxide coating on the surface area. It functions particularly well for oxidation and pitting in moist, chemical, and high-temperature zones. Also, in cases of welding prone to intergranular erosion, the low-carbon variant 308L improves intergranular erosion. These factors allow the use of 308 stainless steel for industrial, marine, and high-temperature settings.

Understanding Austenitic Stainless Steels

Austenitic stainless steels are a group within the classification of stainless steels with high chromium and nickel content. These elements offer remarkable mechanical and corrosion properties, particularly at elevated temperatures. To the best of my knowledge, they possess non-magnetic attributes under most conditions, obtaining/evolving this structure through nitrogen, manganese, and nickel. These steels are mostly used in construction, food processing, and chemical equipment due to their non-weld cracking and formability. Their resistance to environmental factors ensures reliability in harsh, demanding applications.

Factors Affecting Corrosion Resistance

- Chemical Composition

Stainless steels are corrosion resistant because of chromium, nickel and molybdenum. These elements affect the composition and corrosion levels of stainless steel.

- Chromium (Cr) – A stainless steel with at least 10.5% chromium can endure corrosion as it creates a passive protective layer or oxide, which hinders oxidation.

- Nickel (Ni) – Makes austenitic grades about 8-10% less susceptible to acidic environments.

- Molybdenum (Mo) – is used about 2-3% in stainless steel as it enhances ability to endure pitting and crevice corrosion.

- Environment

The environmental conditions have a drastic impact on the rate of corrosion.

- Temperature: An increase in heat, especially in areas rich in chloride, causes an increase in the rate of corrosion.

- Concentration of Chloride: Higher levels elevate the risk of Pitting.

- Surface Finish

To enhance the resistance of the material against corrosion, smoother surface finishes are advisable as it becomes easier to remove contaminants:

- Parameters: To achieve a value of cleanliness for the surfaces of stainless steel, Ra of ≤0.5 µm needs to be set as a roughness value.

- Maintenance and Cleaning

Prevention of localized corrosion caused by deposits can be achieved through regular maintenance.

- Use of Cleaning agents which do not base on chloride is advisable as they will not leave residue that can damage the material over time.

Through careful analysis of these conditions, the right materials that will withstand certain operational conditions and have lowered corroding capabilities can be selected.

Comparative Analysis: 304 vs 308 Stainless

As per my findings, the key distinction between 304 and 308 stainless steel rests in their composition and particular uses. As stated in the description above, 304 stainless steel as an austenitic grade possesses good corrosion resistance, versatile uses, and makes up of approximately 18% chromium and 8% nickel. It is ubiquitous in constituents that require cleansing, such as food processing equipment and medical instruments.

In another manner, 308 stainless steel seeks to cover specific requirements in welding and therefore incorporates 20% chromium and 10% nickel. This addition contrasts 308 stainless steel with 304 in some aspects; mainly in strength against oxidation and rust. The result: An effective filler in welding 304 stainless.

The main specifics are:

304 Stainless Steel:

- Chromium content: ~18%

- Nickel content: ~8%

- Operating temperature range: Up to 870°C (1600°F)

- Applications: Food processing, chemical containers, architectural components.

308 Stainless Steel:

- Chromium content: ~20%

- Nickel content: ~10%

- Operating temperature range: Mildly higher, ideal for welding applications.

- Applications: Used primarily filler in welding with 304 stainless steel.

Apart from other factors, both grades possess strong corrosion resistance. In conclusion, the decision hinges on the precise mechanical requirements, side effects of the environment, and working conditions of the stainless steel in question.

References

- SteelPro Group: 308 Stainless Steel Overview – Provides detailed information on the composition and characteristics of 308 stainless steel.

- AZoM: Stainless Steel – Grade 308 (UNS S30800) – A comprehensive article on the properties and uses of grade 308 stainless steel.

- Stainless Structurals: 308 Austenitic Grade – Offers insights into the applications and specifications of 308 stainless steel.

Frequently Asked Questions (FAQ)

Q: What is grade 308 stainless steel?

A: Grade 308 stainless steel, often referred to as UNS S30800, is a type of stainless steel known for its good corrosion and wear resistance. It is commonly used in welding applications, especially as a filler material due to its similar composition to 304 stainless steel.

Q: What are the physical properties of grade 308 stainless steel?

A: The physical properties of grade 308 stainless steel include good toughness, moderate conductivity, and notable wear resistance. It typically contains a balanced amount of chromium and nickel, contributing to its high corrosion resistance.

Q: How does the thermal properties of grade 308 stainless steel compare to other stainless steels?

A: The thermal properties of grade 308 stainless steel offer moderate thermal conductivity and good thermal expansion characteristics. It performs well under high-temperature conditions, making it suitable for various applications, including those requiring high corrosion resistance.

Q: What makes grade 308 stainless steel a good choice for welding applications?

A: Grade 308 stainless steel is favored in welding due to its good weldability and compatibility with different filler materials like 316L filler material. Its similar composition to 304 stainless and higher nickel content enhance its performance in welding processes.

Q: How does the amount of chromium and nickel affect the properties of grade 308 stainless steel?

A: The amount of chromium and nickel in grade 308 stainless steel is crucial for its high corrosion resistance and overall durability. Chromium helps in forming a passive layer that prevents rusting, while nickel enhances toughness and corrosion resistance, especially in harsh environments.

Q: Can grade 308 stainless steel be used as a filler wire?

A: Yes, grade 308 stainless steel is commonly used as a filler wire in various welding applications. Its good corrosion and wear resistance, along with good weldability, make it an ideal choice for joining or repairing stainless steel components.

Q: What are some typical applications of grade 308 stainless steel?

A: Typical applications of grade 308 stainless steel include its use in the manufacturing of welding wire, stainless steel filler materials, and components exposed to high corrosion environments. Its properties make it suitable for both industrial and commercial uses.

Q: How does grade 308 stainless steel compare to martensitic stainless steels?

A: Grade 308 stainless steel differs from martensitic stainless steels in terms of composition and properties. While martensitic types are known for high hardness and strength, grade 308 offers better corrosion resistance and weldability, making it more suitable for applications that require these properties.

Q: Is annealing necessary for grade 308 stainless steel?

A: Annealing can be performed on grade 308 stainless steel to relieve stress and improve its physical properties. However, it is generally not always necessary unless specific conditions or applications demand enhanced toughness and reduced brittleness.

Q: What role does manganese and sulfur play in grade 308 stainless steel?

A: Manganese and sulfur in grade 308 stainless steel help improve its machinability and overall forming characteristics. While manganese contributes to its strength and hardness, sulfur aids in the machinability, making it easier to process and fabricate.