Selecting the appropriate grade of stainless steel for your project could be crucial towards it performance, durability, or even cost effectiveness. 316 and 416 stainless steel are two popular options being compared for different applications. But, which one is best suited for your requirements and how do they differ?

In this article, I will aim to provide 416 and 316 stainless steel comparison in terms of composition, mechanical properties, corrosion resistance, machinability and applications of each. Whether you are a professional in engineering, manufacturing or construction, this post will help address the factors needed to determine the most appropriate grade of stainless steel to utilize. By the end of the guide, you will understand the major differences between the two materials and the key pointers to focus on while selecting the grade.

Understanding the Difference Between 416 and 316 Stainless Steel

Difference in Composition

For both 316 and 416 stainless steel, their composition marks a notable difference. Unlike other types, 416 stainless steel is a martensitic grade that contains sulfur to improve machinability. As a result, it is suitable for high-precision machining projects. However, this sulfur will decrease his corrosion resistance as opposed to 316. In contrast, 316 stainless steel is an austenitic grade that contains more chromium, nickel, and an addition of molybdenum, which increases corrosion resistance, especially in marine or chemical industries.

Mechanical Properties

From a mechanical perspective, 316 is known for its higher strength and hardness after heat treatment, while 416 is known for being softer but having greater ductility. As a result, 416 is more suitable for applications requiring greater durability and wear resistance. Because of its ease of welding and non-magnetic propeties, 316 is ideal for use in magnet sensitive environments.

Resistant to Corrosion

Both types of steel are resistant to corrosion; however, 316 is more effective due to the addition of molybdenum, which aids in preventing pitting and crevice corrosion. This makes it suitable for use in saltwater or acidic conditions. 416 also possesses some level of corrosion resistance, but due to the sulfur content, it is more susceptible to rust in harsh conditions.

Applications

The selection of 416 vs. 316 is dictated by the application. For stainless steel grade used in precision machining that has moderate corrosion resistance, 416 presents a reasonably priced solution. However, in more demanding environments with high corrosion resistance and weldability requirements, 316 is preferable.

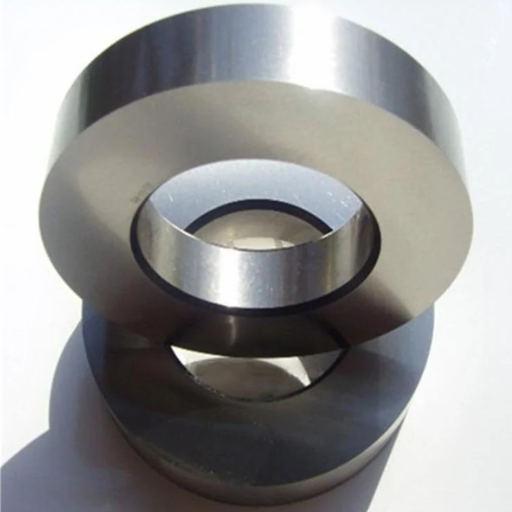

What is 416 Stainless Steel?

416 stainless steel maintains a range of chronic corrosion resistance along with decent mechanical strength, making it ideal for components such as gears, fasteners, and valve elements. This martensitic grade’s exceptional sulfur content allows for great machinability, resulting in its popularity for precision-fabricated components. However, 416 does not fare well under harsh or acidic environments due to its lower resistance when compared to austenitic grades.

Technical Parameters of 416 Stainless Steel:

- Composition:

- Chromium (Cr): 12-14%

- Manganese (Mn): 1.25% max

- Sulfur (S): 0.15% min Phosphorus (P): 0.06% max

- Carbon (C): 0.15% max Tensile Strength: Approximately 74,000 PSI (510 MPa)

- Yield Strength: Approximately 37,000 PSI (255 MPa)

- Hardness: Typically around 262 HB in the annealed condition

- Density: 7.7 g/cm³

- Magnetic Properties: Strongly magnetic due to its martensitic structure

Care should be taken when operating in areas with high moisture or acidic exposure to prevent rusting. Non-critical industrial applications benefit highly from the corrosion resistance of 416 stainless steel.

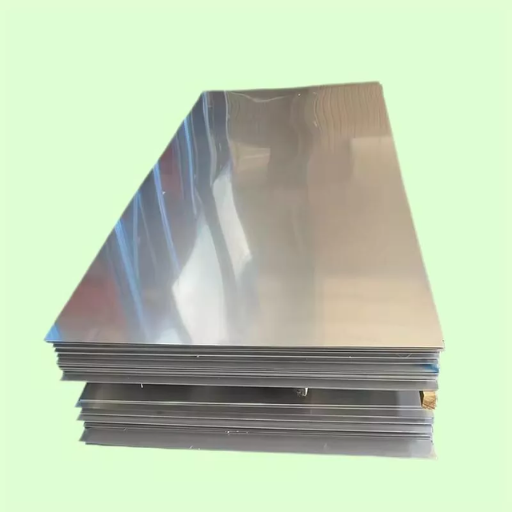

An Overview of 316 Stainless Steel

316 stainless steel is a type of austenitic alloy with extreme anti-corrosive properties, even in extreme conditions, due to the addition of molybdenum, which strengthens its resistance against pitting and crevice corrosion in chloride, marine, and chemical industries. With incredible strength and endurance, it is used in chemical processing, medical implants, and marine hardware.

It’s non-magnetic in its annealed state but can exhibit slight magnetism when cold-worked. Other properties include tensile strength approximately equaling 70,000 PSI (485 MPa) and a density of 8.0 g per cm. Furthermore, this material is outstanding at high temperatures while maintaining its properties at high temperatures. Its machinability is minimal when compared to 416 stainless steel, but with the correct tools, techniques, and approaches, it is still accessible.

In summary, this stainless steel grade is an extraordinary option for areas with high strength, endurance, and anti-corrosive features, particularly in environmental and industrial conditions where other metals simply fail.

Key Differences Between 416 and 316

In the stainless steel family, there are 416 and 316 stainless steel, and with these two, there is a composition difference in properties and applications as listed below.

- Corrosion Resistance

316

Like all alloys, 316 has excellent corrosion resistance/retardation thanks to its high chromium (16-18%) and nickel (10-14%) content along with 2-3 % molybdenum which provides additional protection againts pitting and crevice corrosion.

Marine and chemical processing environments, as well as areas at risk of chloride exposure, are ideal candidates.

416

Moderate corrosion resistance due to less chromium (12-14%) and insufficient molybdenum, nickel, and carbon.

Only appropriate for use in dry or mildly corrosive surroundings, far removed from marine or highly corrosive applications.

- Strength and Hardness

416

Best known for high machinability, 416 stainless steel can be qualifed with a lack of maintaining hardness and strength through heat treatment. Its tensile strength is typical at ~74,000 psi and exceeds 100,000 psi after heat treatment.

316

Possesses remarkable mechanical strength with a tensile strength of ~70,000 psi (annealed) but suffers from hardness due to heat treatment because this is an austenitic stainless steel.

- Machinability

416

Increased sulfur results in a decrease in carbon free cutting steel providing remarkable machinability to 416 stainless steel earning a machinability rating of ~85% compared to free cutting carbon steel.

Frequently applied for manufacturing shafts, fasteners, and more intricate components such as gears.

316 Stainless Steel:

More difficult to machine without specialized tooling or methods, having a lower rate of around ~50% for machinability.

Primarily used in processes where fabrication along with ease of manufacturing is not a concern, gaining high attention in other workings focusing on endurance against corrosion.

- Magnetism:

416 Stainless Steel:

Permanently magnetic in all conditions due to twisting of ferritic-martensitic constituents.

316 Stainless Steel:

Nonmagnetic in nature, but cold-working can lead to minor magnetism.

- Thermal Properties:

416 Stainless Steel:

Lower resistance to high temperatures with a maximum continuous working temperature of ~750°F (399°C).

316 Stainless Steel:

Sustains its properties even under high temperatures, with intermittent use up to ~1500°F (815°C).

Summary Table of Technical Parameters

| Parameter | 416 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chromium Content | 12-14% | 16-18% |

| Nickel Content | ~0.5% | 10-14% |

| Molybdenum Content | None | 2-3% |

| Corrosion Resistance | Moderate | Excellent |

| Tensile Strength (Annealed) | ~74,000 psi | ~70,000 psi |

| Machinability Rating | ~85% | ~50% |

| Magnetic Properties | Magnetic | Non-magnetic (slightly magnetic when cold-worked) |

| Max Operating Temp | ~750°F (399°C) | ~1500°F (815°C) |

Both types of stainless steel have their strengths and optimal use cases. The choice depends on specific requirements such as corrosion resistance, strength, machinability, and environmental conditions.

Comparing the Corrosion Resistance of 416 and 316

In the case of comparing the corrosion resistance of stainless steels 416 and 316, 316 stands out due to its high chromium and molybdenum content, which allows better corrosion resistance in extreme environments. 316 specifically excels in marine or acidic environments where corrosion is a risk. 416, on the other hand, has some corrosion-resisting properties because of its chromium content, but is more prone to corrosion and rusting, particularly in moist, corrosive environments. Therefore, for applications needing better corrosion protection, 316 is the better choice.

How Does 316 Stainless Steel Perform in Corrosive Environments?

From what I understand, because of the high molybdenum content, 316 stainless steel has superior performance in corrosive environments due to the enhanced resistance to pitting and crevice corrosion. In addition to this, 316 performs extremely well in marine environments where saltwater exposure could be damaging. The durability under acidic and chloride-rich environments allows 316 to outperform many alternatives competing in the same industry. Industries that need dependability in challenging environments opt for 316 due to its proven track record.

Examining the Resistance to Corrosion in 416

Type 416 stainless steel is a martensitic grade that has a moderate level of corrosion resistance available under very specific conditions. Its chromium component, roughly around 12-14%, gives it the ability to resist rust and light atmospheric exposure. However, because of lower chrome content and relatively higher sulfur content introduced to improve machinability, 416 has reduced resistance to corrosion compared to austenitic grades like 316.

Some important technical factors affecting its corrosion resistance are:

- Chromium Composition: 12-14%

- Sulfur Composition: ~0.15% (higher machinability leads to lower corrosion resistance)

- Operating Environment: Best suited for dry or mildly corrosive environments; performs poorly in marine or chloride-rich environments.

- Passivation Potential: Proper application of passivation treatments can improve resistance to surface corrosion.

Although 416 is best for circumstances that involve precision machining and moderate exposure to the environment, it is not very effective when it comes to highly corrosive or submerged conditions that require greater resistance.

Exploring Mechanical Properties of 416 and 316

Mechanical Properties of 416

Type 416 stainless steel is a martensitic grade primarily because of its sulfur content, and this attribute makes it extremely easy to machine. Its strength and hardness are moderate. The tensile strength often lies between 480 and 760 MPa depending on heat treatment, however, 416 does show some level of corrosion resistance, which is not great compared to austenitic grades, so it cannot be used in hostile environments. Due to its strength and resistance to wear, 416 is ideal for use in the bushings, pumps, and valve parts industries where moderate wear, ease of machining, and durability are key.

Mechanical Properties of 316

Type 316 stainless steel is an austenitic grade with increased corrosion resistance because of molybdenum content. It has high tensile strength between 515 to 750 MPa and excellent ductility. This makes it a highly preferred alloy in marine applications or industries that deal with chlorides and other harsh chemicals. Additionally, 316 excels in impact resistance over a wide range of temperatures, making it ideal for cryogenic and high-heat applications. Common applications include marine fittings, tanks, and medical devices, where strength and resistance to corrosion are important.

Summarizing these properties, it is evident that at a lesser aggressive environment, 416 is more favorable for machinability and wear resistance, while for more severe conditions, 316 is more favorable for corrosion resistance and durability.

Understanding Hardness in 416

The considerations regarding 416 stainless steel’s hardness must also account for its machinability, which is exceptional due to the high sulfur content. This grade is capable of obtaining very smooth surface finishes and is often heat-treated to improve strength and wear resistance. Generally, after proper heat treatment, 416 has a Rockwell hardness of approximately 35-45 HRC, representing a favorable level of machinability relative to durability. This level of hardness makes it useful in applications such as gears and fasteners, where moderate resistance to wear is adequate. Though it is less resistant to corrosion than some grades, such as 316, it is acceptable in less aggressive environments and is therefore useful for some industrial applications.

How Does 316 Stainless Steel Hold Up in High Temperatures?

316 stainless steel is well-known in high-temperature applications due to its thermal resistance. It keeps its mechanical properties as well as its resistance to corrosion at elevated temperatures, which are in the range of 316 stainless steel’s preferred temperatures. More precisely, 316 stainless steel can withstand continuous use at 1600°F (871°C) while intermittent use can be done at 1700°F (927°C). Its chromium and nickel content are responsible for oxidation and scaling resistance, while modulation‘s feature against corrosion also adds to 316 stainless steel’s charm. That is why 316 stainless steel is used in heat exchangers, furnace parts, and chemical processing equipment.

The Machinability of 416 vs 316 Stainless Steel

In comparison with 416 stainless steel, both in terms of its machinability and parts production, 416 comes out on top. The steel is much easier because of its higher sulfur content hence it is popular for mass production where default standards are needed. 316 stainless is however known to be more diffictult to machine because of its nickel and molybdenum which give steel rigidity. For differences, 416 is more preferred in high machinability applications while 316 boast higher corrosion resistance and strength.

Why 416 Stainless Steel Offers Excellent Machinability

The chemical composition and microstructure of 416 stainless steel contribute to its superb machinability. 416 stainless steel has a moderately high sulfur content ranging from 0.15% to 0.35%. This sulfur content improves free-cutting capabilities by improving chip breaking during machining operations. Because 416 is a martensitic stainless steel, it contains a lower amount of chromium (12-14%) relative to other stainless steels, such as 316. This lower chromium content increases machinability at the cost of reduced toughness. Further tailoring his hardness and strength through heat treatment to optimize machinable properties makes machining easier.

Key Technical Parameters:

- Sulfur Content: 0.15% to 0.35% – Enhances efficiency by increasing chip breaking.

- Chromium Content: 12-14% – Widely known to reduce corrosion but in this instance improves machining properties.

- Hardness: ~200 HB Aged – Softer than more resilient stainless steels, more suitable for machining.

- Yield Strength: ~275 MPa Aged – Prevents material removal during machining.

These traits champion 416 stainless steel as a choice for surgical precision bored parts as they minimize stamp wear and production expenses.

Challenges of Machining 316 Stainless Steel

In my experience, 316 stainless steel presents several challenges for machining because of its high toughness and work-hardening properties. Elliptical cutting is exacerbated when a tool’s sharp edge is blocked by heat and counter-rotating against the workpiece. Moreover, stainless steel offers undue elasticity, which increases toughening and work hardening to form a stronger material. Imperfect techniques greatly complicate the process. Still, there is no way to mitigate exceeding temperature, wear soft tools, and use slower speeds without losing efficiency. Correctly using lubricants greatly improves efficiency. Additionally, using tipped or coated carbide tools is essential to maintaining precision. Understanding these obstacles for a balance for 316 stainless steel is daunting.

Choosing the Right Stainless Steel for Your Application

It is essential to consider a particular project’s requirements when selecting stainless steel for an application. Corrosion resistance, strength, and machinability are some of the major determining factors. For environments susceptible to strong chemicals or high salt concentrations, 316 stainless steel is often more appropriate because of its ability to withstand pitting and crevice corrosion. Alternatively, 304 stainless steel is a general-purpose stainless steel that is cost-efficient and broadly applicable. Even further specialized grades may be needed for high temperature or greatly stressed environments. Be sure to evaluate your operating conditions and budget to make sure that the selected material will meet your performance criteria.

When to Use 316 Grade for Food Processing

I recommend using 316 stainless steel for food processing applications in corrosive environments containing acidic or salty materials. Its superior resistance to pitting and crevice corrosion is also advantageous on equipment that must undergo frequent cleaning because of strict food safety standards. In addition, 316 grade is better in scenarios encountered with high humidity, heat, and where long-term durability is critical to ensure sustained reliability and compliance to standards.

Applications Suited for 416 Stainless Steel

I would suggest that 416 stainless steel be used for cases where its machinability is of utmost priority because out of all the stainless steel grades, it manages to retain one of the highest ratings in terms of machinability. It is especially good for use in regions where moderate corrosion resistance is permissible, for example, areas that are dry or mildly corrosive. Its common uses include the manufacturing of screws, gears, shafts, and valves. When compared to other materials, it offers decent mechanical properties, like around 74000 psi in tensile strength and 39900 psi in yield strength. Because of these factors, stainless steel 416 is often used for components that require precision machining. Also, further improving its properties is possible with heat treatment, making it suitable for parts that experience abrasion during regular operation. Its use is not advisable in case severe corrosive materials or marine areas are present because of its lesser resistance to corrosion when compared to other grades.

References

- AISI 316 Stainless Steel vs. AISI 416 Stainless Steel – MakeItFrom.com

- 416 Stainless Steel vs. 316: Key Differences – MFG Shop

- 316 vs 416 Stainless Steel: Properties and Applications – Machining Quote

Frequently Asked Questions (FAQ)

Q: What are the main differences between stainless steel 416 and 316?

A: The main differences lie in their composition and properties. Stainless steel 416 is a martensitic type of stainless steel known for its high strength and hardness, which make it suitable for machining applications. In contrast, stainless steel 316 is an austenitic stainless steel with excellent corrosion resistance, especially in chloride environments, making it ideal for chemical processing applications.

Q: How does the corrosion resistance of stainless steel 316 compare to 416?

A: Stainless steel 316 offers superior corrosion resistance compared to 416. The austenitic structure of 316 stainless steel provides excellent protection against pitting and crevice corrosion, especially in chloride-rich environments, while 416 stainless steel may be more susceptible to corrosion.

Q: What applications are best suited for 416 stainless steel rods?

A: 416 stainless steel rods, being a martensitic grade, are ideal for applications requiring high strength and high hardness, such as in the production of gears, screws, and valves. The grade’s machinability makes it particularly suitable for components that need extensive machining.

Q: Can stainless steel 416 be welded easily?

A: Welding stainless steel 416 can be challenging due to its high carbon content, which can lead to cracking. Preheating and post-weld heat treatment are often necessary to improve weldability and reduce the risk of cracking.

Q: Why is AISI 316 stainless steel preferred in chemical processing?

A: AISI 316 stainless steel is preferred in chemical processing due to its excellent corrosion resistance, especially against chemicals and acidic environments. Its austenitic structure and alloying elements, such as molybdenum, enhance its durability in harsh conditions.

Q: How do the mechanical properties of stainless steel 416 and 316 compare?

A: Stainless steel 416 has higher strength and hardness, making it advantageous for applications requiring wear resistance. In contrast, stainless steel 316 offers better ductility and toughness, which are essential for applications that demand flexibility and impact resistance.

Q: What are the benefits of using a stainless steel rod from grade 316?

A: A stainless steel rod from grade 316 provides high corrosion resistance, which is particularly beneficial in marine and chemical environments. Its durability and resistance to pitting and crevice corrosion make it a reliable choice for structural and infrastructural applications.

Q: How does the cost of 416 stainless steel compare to 316?

A: Generally, 416 stainless steel is less expensive than 316 due to its lower corrosion resistance and simpler alloy composition. However, the choice between the two should be based on the specific requirements of the application rather than cost alone.

Q: Why might one choose 416 stainless steel over 316, despite its lower corrosion resistance?

A: One might choose 416 stainless steel over 316 if the application requires high machinability, high strength, and hardness, such as for precision components. If the environment is not highly corrosive, 416 can be a cost-effective and practical choice.