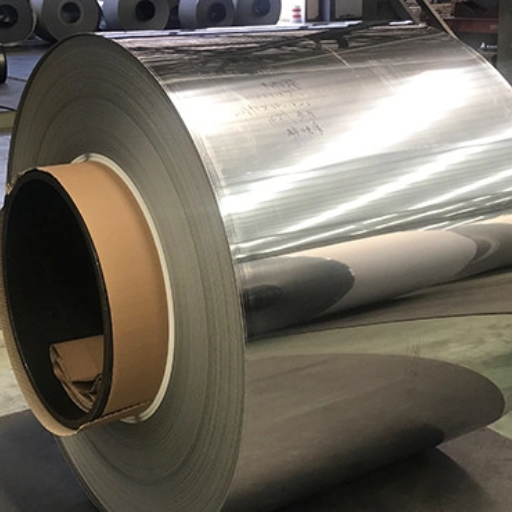

430 stainless steel coils and strips, like all other 430 stainless steel products, are valued for their durability, corrosion resistance, and cost-effectiveness. This article will cover the most critical features, benefits, and uses of 430 stainless steel coils. It will also explain why importing them from top manufacturers in China is a smart move for many companies. We will review the development criteria, the significant characteristics of 430 stainless steel, and the information on the best producers in China known for outstanding quality products. In conclusion, I will state why 430 stainless steel coils are in high demand and how to obtain materials that suit your requirements.

What is 430 Stainless Steel, and Why is it Popular?

Grade 430 stainless steel possesses many good qualities, such as affordability, ease of fabrication, and versatility. This non-hardenable stainless steel grade is widely known for its impressive formability and resistance to corrosion. While its oxidation-resistant properties are substantial due to the grade’s high chromium content, the smooth surface finish helps improve the aesthetic appeal of the material, making it suitable for both functional and decorative applications. These applications include kitchen equipment, automobile trim, and industrial machinery components.

Understanding the Composition of 430 Stainless Steel

To my knowledge, and in summary, 430 stainless steel is made mainly of iron and chromium. The chromium amounts, usually 16 – 18%, provide exceptional oxidation resistance and corrosion-resistant features over time. It is also low in nickel or utterly devoid of it, bringing down the price and making it quite different compared to grade 304 stainless steel. In addition, trace amounts of manganese and silicon are included in alloys to improve strength and toughness, with a restriction of carbon to improve weldability and lower brittle-ness. Because of these reasons, 430 stainless steel is considered economical and practical for many applications that need formability and wear resistance.

The Role of Chromium in 430 Stainless Steel

Chromium boosts corrosion resistance and oxidation stability in 430 stainless steel. In this chrome alloy, which is precisely 16% to 18% chromium, a passive oxide layer is formed on its surface, and environmental degradation in the form of rust is safeguarded against. This makes it appropriate for use in mildly corrosive settings like appliances used for cooking, automotive trims, and architectural fittings. However, due to the lack of nickel, it doesn’t perform as well as 304 stainless steel in highly corrosive environments. The chromium content guarantees performance at elevated temperatures, thus making it suitable for specific heat-resistant applications.

Applications of 430 Stainless Steel in Various Industries

Due to its cost-effectiveness and functionality, many industries use 430 stainless steel. It is commonly used in trim and exhaust systems in the automotive industry because of its resistance to mild corrosion and heat. It is also used in many kitchen appliances, such as oven liners and range hoods, because it is easy to clean and aesthetically pleasing. Furthermore, it is utilized in some architectural needs, like decorative panels and elevators, where durability and appearance are essential. Even though it may not deal best in highly extreme environments compared to other alloys, it still is undeniably helpful for many industries.

How Are 430 Stainless Steel Coils Manufactured?

Producing 430 stainless steel coils requires a series of steps. The first step involves melting raw materials such as iron, chromium, and other alloys in a furnace. After achieving the desired chemical composition, the molten steel is cast into slabs and then hot rolled to improve structural properties and reduce thickness. The coils are then cold rolled to refine the surface finish further and enhance accuracy. The coils are also annealed to relieve internal stresses and guarantee optimal ductility and hardness. Coils are then cleaned and polished before being prepared for distribution.

The Cold Rolled Process for 430 Stainless Steel Coils

Cold-working 430 coils start with rolling the stainless steel at room temperature. The rolled steel’s thickness is reduced while the metal’s surface is improved, enhancing the casing, where the material appears to be polished. The next step involves the coils being polished through annealing to be shaped and fabricated correctly as they become more malleable. The last step involves thoroughly cleaning the materials, followed by inspection to ensure stringent standards are met before application usage.

Differences Between Hot Rolled and Cold Rolled 430 Stainless Steel

The core differentiation of hot and cold rolled 430 stainless steel is in manufacturing, significantly affecting the product’s characteristics. For instance, hot rolled 430 stainless steel has high-temperature processing, which occurs above its recrystallization point. This simplifies forming the steel; however, the surface finishes and dimensions are less defined. Cold rolled 430 stainless steel is processed further around room temperature, which increases strength due to work hardening while giving the steel a softer surface with tighter tolerances in dimensions.

Comparison of Technical Parameter:

- Surface Finish:

- Hot Rolled: Rougher finish

- Cold Rolled: Smooth, polished finish (e.g., BA or 2B finishes)

- Dimensional Tolerances:

- Hot Rolled: Less precise due to cooling shrinkage

- Cold Rolled: More precise due to consistent dimensioning

- Thickness Range:

- Hot Rolled: Typically thicker (3mm or above)

- Cold Rolled: Available in thinner sizes (down to 0.3mm)

- Mechanical Properties:

- Hot Rolled: More ductility and less tensile strength

- Cold Rolled: More tensile strength due to strain hardening

Working with the two methods above yields different results for productivity. Cold-rolled material yields better results with projects that require more attention to detail and craftsmanship. At the same time, hot-rolled procedures are more economical for structural applications where surface finish and dimensional accuracy are not as critical.

Both alternatives possess a level of corrosion resistance like that of 430-grade stainless steel.

Quality Control Measures in Coil Manufacturing

Meticulous inspection is indispensable at every step in the production cycle, mainly when richness, durability, and functionality are at stake. This is likely the most crucial step that is persistently upheld:

- Checking the Quality of Raw Material

- Chemical Composition Checks: Special criteria that inform tests such as carbon and stainless steel chromium tests.

- Visual inspection: It helps to determine if there are surface flaws like cracks, rust, or inclusions.

- Checking Dimensional Accuracy

- Thickness Tolerance: Considered sufficient for sensors’ ultrasonics micrometers or gauge systems micrometer measurement capabilities. (±0.01 mm).

- Width Tolerance: Consistent checks for non-uniformity within permissible levels († 0.5 mm).

- Surface Quality Control

- Roughness Value of the Surface: Measures surface finish for usability in a given application. The average specifications for added targets, Ra for cold rolled, may vary between 0.2 and 0.6.

- Coating and polishing for corrosion protection: Checks for protective coating where necessary.

- Mechanical Properties Testing

- Tensile Strength Test: This test probes the coil’s performance. For instance, steel that has gone cold rolling (roll height of 50 mm) should be above 450 MPa in strength.

- Hardness Tests: Ensures that the bends of the Blinell and Rockwell methods are needed based on specification-verified values.

- Flatness and Edge Inspection

- Flatness Checking: Estimates the coil for any distortion or waves that may have formed throughout manufacturing.

- Edge Examination: Analyze the edges to ensure they are smooth and devoid of any burrs, cracks, or even deformations.

- Process Monitoring and Final Inspection

- Process Monitoring: Deploy sensors, cameras, and automated systems to monitor manufacturing processes to improve efficiency, accuracy, and effectiveness.

- Final Inspection and Quality Control: The final inspection is done before wrapping in packaging to ensure all side parameters are checked and labels are on the tags for traceability.

If manufacturers follow these quality measures and apply new testing methods, they will always meet the coils set requirements for the industry and customers.

What to Look for in a 430 Stainless Steel Coil Factory?

When choosing a factory for the 430 stainless steel coils, one must consider the reputation and reliability of the factory. Facilities that utilize state-of-the-art machinery and advanced technologies must be prioritized to ensure accurate and precise product manufacturing. Confirm the factory’s industrial claims, which are ISO 9001 guaranteed, are an affirmation of quality management and adherence to industry standards. Also, look through the factory’s claimed quality control operations, covering all ranges of raw material evaluations and testing of final products. A factory’s customer support, coupled with the capability of fulfilling specific required solutions, is a sign of a reliable factory.

Key Qualities of a Reliable Coil Manufacturer

To me, the most critical aspect of a coil manufacturer is its reputation for quality and reliability. A reputable manufacturer must hold certifications like ISO 9001 that indicate the existence of effective quality management systems. Quality control procedures, including all inspection points from raw materials to final testing, must be assessed. Furthermore, I prefer manufacturers who offer exceptional customer service and are willing to go the extra mile to accommodate my needs. Trusting them to meet my expectations becomes more manageable with these aspects in mind.

Evaluating Corrosion Resistance and Mechanical Properties

In evaluating corrosion resistance, elements such as the exposure of the material to the environment, the presence of corrosive substances, and the material’s corrosion rate need to be analyzed. Technical parameters to review include pitting potential, crevice corrosion resistance (ASTM G48 or the equivalent), and salt spray test results (ASTM B117). Constructed from metals with high corrosion resistance, such as stainless steel, certain alloys, and titanium, these materials are most appropriate for harsh environments.

Tensile strength, yield strength, elongation, and hardness are essential for mechanical properties. Standard tests like ASTM E8 and ASTM E18 for tensile and hardness tests should be conducted. Also, verify that the material fulfills your needs, such as impact resistance (Charpy test results) for dynamic loading or fatigue strength for cyclic loads. Industry tests and certifications have become a trustworthy basis for evaluation because they are aligned with standards.

Certifications and Standards to Consider

When thinking about materials and their certifications or standards, I personally pay attention to the most popular, like ISO 9001 for quality management systems, ASTM for material testing, and ASME for mechanical applications. Following these ensures that the material is of good quality and reliable for the expected use. Furthermore, I check if there are industry-specific certifications like API for petroleum equipment or Nadcap for aerospace. These materials are known to be more reliable because they guarantee adherence to best practices.

Comparing 430 Stainless Steel Coils with Other Grades

430 stainless steel is ferritic with good corrosion resistance, especially in mildly corrosive environments. It is particularly noted for its resistance to nitric and organic acids, making it useful in kitchen appliances and automotive trims. However, unlike austenitic grades such as 304, 430 is less formable and weldable because it does not contain nickel. While 304 is more usable in a wide range of environments and applications that require high ductility and high resistance to severe corrosion, 430 is the best fit for less demanding environments in a more economical option. Moreover, other grades, such as 316, contain molybdenum, which increases pitting resistance and certainly outperforms 430 in other highly corrosive conditions. Hence, choosing the best grade balances costs, mechanical properties, and environmental exposure.

430 vs 304 Stainless Steel: Which is Better for Your Needs?

Your personal needs and working contour will determine whether to select 430 stainless steel or 304 stainless steel. Here is a brief comparison to assist you in your selection.

- Corrosion Resistance: 304 stainless steel is more resistant to corrosion than 430 stainless steel due to its higher percentages of nickel (8-10.5%) and chromium (18-20%), making it preferable in environments with high humidity levels, marine exposure, or chemical exposure. Of the metals 430 contains, chromium (16-18%) is the only form of nickel present. This is why stainless steel 430 is less corrosion-resistant than 304 but performs better in dry indoor environments.

- Mechanical Properties:

- Tensile Strength of 304: ~ 505 MPa (73,200 psi)

- Tensile Strength of 430: ~ 450 MPa (65,300 psi)

- Yield Strength of 304: ~ 215 MPa (31,200 psi)

- Yield Strength of 430: ~ 310 MPa (45,000 psi)

- Welding and Formability:

- 304 is weldable and formable, enabling its use in joints requiring complex shapes and intense bonds.

- 430 is sufficiently strong for simpler shapes and non-critical welds but is not as formable or weldable as 304.

- Cost:

- Allowable budget constraints will increase the effectiveness of 430, as it is cheaper due to the lack of nickel, making it the best option for economizing options with few expectations.

- In more demanding and critical applications, 304 is more costly but performs better.

Recommendation:

If your application requires a higher level of corrosion resistance along with enhanced strength and versatility, 304 is the most suitable option. On the other hand, 430 is a dependable choice for cases where corrosion exposure is limited, and cost savings are a priority. For the optimal selection, be sure to factor in the environment and any mechanical stress.

The Advantages of Ferritic Stainless Steel

Ferritic stainless steel has many benefits that make it suitable for many uses. First and foremost, it is far cheaper than austenitic grades and still performs to expectation. It is well-known for its good thermal conductivity and resistance to stress corrosion cracking, which is why it is used in heat exchangers and automotive exhausts. Moreover, ferritic stainless steel is an iron-containing alloy that is magnetic and has excellent oxidation resistance, enabling its use in hot environments. These advantages, outstanding durability, and lower nickel content make ferritic stainless steel economical and practical.

Understanding the Differences in Corrosion Resistance

The resistance of stainless steel to corrosion depends on its composition and microstructure. For instance, austenitic stainless steels corrode less due to their chromium (16-26%) and nickel (6-22%) constituents, which assist in developing a strong passive oxide layer. On the other hand, ferritic stainless steels have lower resistance than austenitic stainless steels, but with moderate chromium levels (10.5-18% ), some resistance can be achieved. However, lacking nickel means these steel types are more prone to stress corrosion cracking.

Duplex stainless steels have a superior structure with increased chromium (19-28%,) moderate amounts of nickel (1-8%), and good strength, aiding in the superior pitting and crevice corrosion resistance. Towards extreme performance, either super austenitic or super duplex stainless steels can be used as these have higher proportions of molybdenum (up to 7%) and nitrogen. These grades must be compared diligently, considering the environmental factors of chloride concentration and temperature and whether oxidizing or reducing agents are present.

How can you source 430 stainless steel coils from China manufacturers?

Begin sourcing 430 stainless steel coils from Chinese manufacturers by looking for suppliers on websites like Alibaba, Made-in-China, or Global Sources. Check the manufacturer’s certifications, like ISO 9001, and their years of experience producing 430 stainless steel. Ask for product details and test reports to confirm no standards violations. Enter into discussions about payment, delivery, and shipping conditions. Before making a large order, it is best to request samples to evaluate first. Working with a reliable sourcing agent or doing factory audits can help guarantee quality and reliability further.

Benefits of Choosing a Chinese Steel Coil Manufacturer

The advantages of Chinese steel coil manufacturers are numerous. First, Chinese manufacturers have a competitive edge because of their economies of scale and production cost advantage. In addition, most Chinese manufacturers are certified with international quality standards such as ISO 9001. They also have numerous products, like specified and graded custom products, that fit many industrial requirements. Together with these manufacturers, I can acquire the materials in bulk after the quality assessment tests, including test reports and product samples. In addition, most Chinese suppliers have extensive industry experience that, coupled with fast lead times and competitive shipping rates, facilitate easier procurement.

How to Verify the Credibility of a 430 Stainless Steel Coil Exporter

To validate the reputation of an exporter of a 430 stainless steel coil, pay attention to the following procedures:

- Confirm Credentials and Results of Certification

Look into whether the exporter observes the requirements of international conventions like ISO 9001 quality management and ASTM A240 for stainless steel specifications. Their products should meet pertinent technical parameters such as a chromium content of 16%—18% and a maximum carbon content of 0.12%.

- Obtain Necessary Reports

Ask for material test certificates (MTC) or mill test reports stating the chemical composition and mechanical properties, such as tensile strength, which should not be less than 450 MPa, and yield strength, which should not be less than 205 MPa.

- Determine Production Capabilities

Establish their production capability by checking monthly output volume, machinery, and existing engineering skills. This guarantees that the exporter can fulfill your order specifications and timeframes.

- Examine Export History

Check whether the exporter has experience in trading with other countries, especially concerning your country’s regulations. Reliable exporters can obtain customs clearance and export documents without any hassle.

- Perform Factory Inspections

Go to their manufacturing location or organize for them to show you around virtually so that you can establish how they manage quality control, the state of equipment, and safety compliance.

- Check Clients’ Reviews and Their Strategic Partnerships

Search for client reviews, case studies, and partnerships with known companies. Enduring positive reviews and business relations is a sign of reliability.

After completing these steps, it is one hundred percent guaranteed that the stainless steel coils will be of the standard parameters and will mitigate risks in the supply chain.

Tips for Ensuring Quality in Wholesale Purchases

After my years of research, here’s how I ensure the quality of wholesale stainless steel coils, combining the best practices of the industry:

- Analyze Material Details

I verify the grade, thickness, and measurements against the project specifications. This guarantees that the material is optimal and will function as intended.

- Collect Certifications and Sample Products

Before placing large orders, I check the supplier’s ISO or ASTM certifications to ensure they meet industry standards. Product samples are also a must.

- Check Wholesaler Reputation

I can trust a wholesaler only when there is enough positive feedback and long-term business partnerships. Supplier reviews accompanied by positive client testimonials indicate excellent quality.

Following these approaches gives me confidence in selecting a supplier while ensuring the highest quality standard measures are implemented, finally eliminating risks found in supply chains.

References

- AISI 430 Stainless Steel Coil – Goodfellow – Provides details on the properties and applications of AISI 430 stainless steel coils.

- 430 Stainless Steel – Penn Stainless – Offers insights into the corrosion resistance and uses of grade 430 stainless steel.

- 430 Stainless Steel Suppliers | Manufacturers in China – Huaxiao – Highlights Huaxiao as a leading supplier and manufacturer of 430 stainless steel in China.

Frequently Asked Questions (FAQ)

Q: What is 430 stainless steel, and where is it commonly used?

A: Type 430 stainless steel is a ferritic, straight chromium, non-hardenable grade known for its good corrosion resistance and formability. Due to its aesthetic appeal and durability, it is commonly used in automotive trims, kitchen sinks, and appliances.

Q: Who are the top 430 stainless steel coil manufacturers in China?

A: Some of China’s leading 430 stainless steel coil manufacturers include TISCO and other reputable steel coil manufacturers and supplier companies. These manufacturers are known for producing high-quality rolled stainless steel products.

Q: What is the difference between cold-rolled stainless steel and hot-rolled stainless steel?

A: Cold-rolled stainless steel is processed at room temperature, which provides a finer surface finish and tighter tolerances compared to hot-rolled stainless steel, which is processed at high temperatures. Cold-rolled stainless steel coils are typically used for applications where precision and surface quality are critical.

Q: What are the benefits of using 430 stainless steel in automotive applications?

A: 430 stainless steel offers excellent resistance to corrosion and good formability, making it ideal for automotive trim and other components where aesthetic appeal and durability are important.

Q: How does 430 stainless steel compare to 304 stainless steel?

A: While 430 and 304 stainless steel are corrosion-resistant, 304 stainless steel offers superior corrosion resistance due to its higher nickel content. 430 stainless steel is more affordable and is often used in applications where the high corrosion resistance of 304 is not necessary.

Q: Can 430 stainless steel be welded, and if so, what considerations should be made?

A: Yes, 430 stainless steel can be welded, although due to its higher thermal conductivity, special techniques may be required to prevent cracking. It is essential to use appropriate welding methods and filler materials to ensure a strong weld joint.

Q: What finishes are available for 430 stainless steel coils?

A: 430 stainless steel coils are available in various finishes, including 2B, a standard, smooth finish for most general applications. Other finishes may include brushed or polished, depending on the application’s specific requirements.

Q: What is the role of a stainless steel coil manufacturer and supplier?

A: A stainless steel coil manufacturer and supplier is responsible for producing and distributing high-quality stainless steel coils, such as 430 coils, to various industries. They ensure that the products meet industry standards, such as ASTM, and provide technical support and customer service.

Q: How can I contact a reliable 430 stainless steel coil manufacturer?

A: To contact a reliable 430 stainless steel coil manufacturer, visit their official websites and look for the “Contact Us” section. There, you will find their contact information, including phone numbers and email addresses for inquiries and orders.

Q: What makes 430 stainless steel a popular choice for kitchen sinks?

A: 430 stainless steel is a popular choice for kitchen sinks due to its resistance to corrosion, ease of maintenance, and aesthetic appeal. Its durability and affordability make it a practical option for residential and commercial kitchens.