The 65mn spring steel is a high-carbon steel alloy containing manganese and is known for its excellent balance of hardness, strength, and toughness. In this blog post, I intend to address the unique properties, applications, and treatments of 65mn spring steel, making it a preferential material in automotive, manufacturing, and other industries. Firstly, we will discuss this spring steel grade’s formulation and unique characteristics, then outline its benefits in functional applications. Moreover, the essential heat treatment methods that greatly influence the potential of steel will be discussed. In the last sentence, the reader will understand why 65 mn spring steel is the best material for modern engineering problems.

What is 65mn Spring Steel?

65mn spring steel is a type of alloy and high carbon steel containing manganese, widely recognized for its exceptional resilience, strength, and hardness. It is predominantly utilized in producing industrial components such as springs, saw blades, agricultural implements, and a host of other tools where high elasticity and durability are crucial. The remarkable composition is ideal to withstand constant cyclic loading while exhibiting low levels of permissible distortion.

Understanding the Chemical Composition of 65mn

Based on my knowledge, 65mn spring steel mainly consists of carbon and manganese, which is beneficial for its ductility and toughness. The carbon percentage is around 0.62% to 0.70%, giving it high hardness and resistance to abrasion. Manganese, which ranges from 0.90% to 1.20%, aids in increasing strength and ductility as well as improving hardenability. Furthermore, some silicon, sulfur, and phosphorus compounds exist, but these are tightly controlled to avoid making the steel brittle and maintain its integrity. With this composition, 65mn is ideal for applications needing high elasticity and fatigue resistance.

Comparison with Other Carbon Steels

Compared to other carbon steels, 65mn is unique due to its superior strength, hardness, and elasticity. For example, 65mn outmatches 60Si2Mn, which has more significant amounts of silicon (1.50%-2.00%) because it is more flexible and has better fatigue resistance. These attributes make 65mn more desirable for constructing springs and cutting tools. On the other hand, lower-carbon steels are better suited for machining due to their relatively lower hardness and tensile strength. For instance, 45# steel, with a carbon content of about 0.42%-0.50%, is easier to process but comes at the cost of wear resistance.

The heat treatment of 65mn is also of note, as it can reach a hardness of 45-52 HRC after being properly quenched and tempered. This allows the material to be used in high-demand applications requiring excellent durability. Hard 40Cr steel does not meet these standards, as it only reaches about 35-45 HRC under the same conditions. The sizable concentration of manganese can also be credited (0.90%-1.20%) for the enhanced hardenability, especially when compared to simpler steels like 30# without such an additive composition.

In summary, while carbon steels do vary in composition to serve particular applications, 65mn stands out as a singularly versatile and high-performing material for components that need to withstand high amounts of strength and loading shocks.

Key Applications and Uses

Due to its strength and resiliency, 65mn steel is helpful in various high-performance applications. It is commonly used in the manufacturing of springs, saw blades, and agricultural tools, such as plow blades. Its enhanced hardenability also makes it ideal for automotive parts, industrial cutting tools, and heavy machinery equipment, which are complex components subjected to dynamic loads. This adaptability ensures that industries that require high durability and mechanical performance will remain relevant.

How Does Heat Treatment Affect 65mn Spring Steel?

The mechanical properties of 65mn spring steel are significantly affected by heat treatment, making it more suited for demanding applications. Processes like quenching and tempering change the microstructure of the steel and improve hardness, strength, and wear resistance. Quenching changes the microstructure of the steel and increases its hardness by forming martensite, while tempering makes the steel less brittle and more challenging. Appropriate heat treatment allows for the right amount of strength and flexibility, which is essential for components constantly undergoing repetitive stress or dynamic loads.

The Role of Heat Treatment in Enhancing Hardness

Regarding the quenching and tempering processes for increasing hardness through heat treatment, quenching must be done rapidly to cool the steel and produce a complex yet fragile martensitic structure. Afterward, tempering needs to be done, which is applying a controlled amount of heat to dissipate the fragility and promote toughness. Finding a balance between toughness and brittleness is crucial in producing high-performance components, especially where parts are subjected to intense stress or wear. From my understanding, treating steel properly with heat is essential for the proper outcome of the mechanical features with the right amount of flexibility.

Steps for Effective Heat Treatment of 65mn Steel

- Preparation of the Steel

Start preparations by degreasing and cleaning the surface of the 65mn steel so it is free from any form of grease, dirt, or rust. Doing so will make sure the treatment to be given later on is as uniform as possible and purified will not interfere with the final mechanical properties of the steel.

- Annealing process

Heat steel to about 750-820°C and maintain this temperature until the steel is uniformly heated. In this case, simply moving your body around will be sufficient. Leave it to slowly furnace to improve its structure and, therefore, its machinability.

- Quenching

Heat the steel to 840 – 860°C, its austenitizing temperature, and hold it for a long time to achieve a uniform structure. Oil or water quenching is advised to bring the temperature below the martensitic transformation point quickly. Depending on the quenching medium chosen, the end product can have a range of hardness and brittleness.

- Tempering

Reheat the steel (200 to 350°C) for varying levels of required toughness to harness and hold the temperature for a determined amount of time. Cooling down afterward should be done in the air. It always aids in decreased brittleness while keeping effectiveness: this is harder than the tempering process.

- Stress Relieving

For those with increased durability requirements, a stress-relieving step is advisable. Put the steel at 150 – 200°C to relieve the internal stresses while keeping the hardness intact.

- Quality Verification

Verify quality by performing comprehensive tests like hardness testing (targeting a hardness rating between 45 and 55 HRC). Microstructure inspection may also be done to check if the heat treatment features were accomplished.

With the appropriate precision on the temperature and time, the 65mn steel will be able to function for more severe purposes after going through optimum treatment.

What are the Mechanical Properties of 65mn Steel?

65MN steel is a high-strength and high-carbon material, making it excellent for wear and tear and rugged usage. The notable mechanical features include a good amount of ductility, strength, and a hardness of around 45 to 55 HRC after being treated with heat, along with high tensile strength. This makes it practical to fabricate springs, blades, and other parts that need the ability to endure a high amount of stress.

Exploring the Toughness and Elasticity of 65mn

65mn steel is tough, enabling it to sustain considerable mechanical stress and impact without breaking. This toughness stems from its high carbon part and suitable heat treatments that improve its durability. In addition, 65mn steel has good elasticity, which is essential for springs and other flexible parts. Elasticity allows the material to return to its original position after being pulled or compressed, making it ideal for dynamic and repetitive loads. These mechanical properties also have an optimum combination of strength, wear resistance, and flexibility, which suits 65mn to severe conditions. These are required to construct systems and structures with heavy load-carrying beams and frames.

Impact of High Carbon Content on Wear Resistance

High carbon content considerably improves the wear resistance by increasing the hardness of the material. This is important because more complex materials are less prone to abrasive forces, which reduces their lifespan when used in rigorous conditions. Furthermore, carbon forms carbides in steel, which enhances its ability to withstand wear and tear for extended periods. This hardness level and the presence of carbides is why high-carbon steel, such as 65mn, is so durable and reliable under harsh conditions.

Comparison with Other Spring Steels

65Mn Spring Steel Comparison with Other Spring Steels Like 60Si2Mn, 50CrV4, SK5: Composition, Performance and Application Differences

Its manganese content exceeds that of 65mn, thus providing more excellent toughness and wear resistance. As an alloying component, silicon is present in 60Si2Mn, which provides much better elasticity and resilience than 65mn. On the other hand, 60Si2Mn is preferred for uses with high fatigue strength, and 65mn is considered more suitable for areas that require hardness alongside abrasion resistance.

- 65mn vs 50CrV4

Adding chromium and vanadium into 50CrV4 (also known as 6150), chromium-vanadium steel increases its strength, fatigue resistance, and impact resistance, making it superior. 50CrV4 is perfect for heavy dynamic loads but comes with a premium. 65mn is much more cost-effective, providing excellent hardness and wear resistance. 50CrV4 is often preferred in heavy-duty springs and automotive parts because of its superior performance under extreme dynamic loads.

- 65mn vs SK5

SK5 is a high-carbon tool steel from Japan popular for its very high edge retention and sharpness. This enables its use in precision cutting tools and blades. While 65mn is more versatile, SK5 is better for applications that require refined cutting performance. Compared to 65mn, SK5 has slightly lower toughness but also greater edge retention.

Key Technical Parameters:

| Steel Type | Carbon (C) | Manganese (Mn) | Silicon (Si) | Chromium (Cr) | Vanadium (V) | Hardness (HRC) | Applications |

|---|---|---|---|---|---|---|---|

| 65mn | 0.62-0.70% | 0.90-1.20% | 0.17-0.37% | – | – | 50-55 | Springs, saws, wear parts |

| 60Si2Mn | 0.56-0.64% | 0.75-1.00% | 1.50-2.00% | – | – | 46-52 | High-performance springs |

| 50CrV4 | 0.47-0.55% | 0.70-1.00% | 0.15-0.30% | 0.80-1.10% | 0.10-0.20% | 48-53 | Automotive, heavy-duty springs |

| SK5 | 0.80-0.90% | 0.30-0.60% | ≤ 0.35% | – | – | 55-58 | Precision tools, cutting blades |

The choice between these spring steels depends heavily on the specific application requirements, including cost, toughness, fatigue resistance, and hardness. 65mn remains a strong contender for many applications due to its balance of performance and affordability.

How to Weld 65mn Spring Steel?

Welding 65mn spring steel involves intricate steps that, if cared for correctly, will culminate in a reliable and strong joint. Here’s the breakdown:

- Preparation: Cleaning the spring involved removing rust, oils, or dirt and preheating the steel to 200-300 degrees Celsius. The temperature helps mitigate the chances of cracks emerging during the welded seam.

- Welding Method: Use low-hydrogen electrodes or other fillers compatible with high-carbon electrodes. Shielded Metal Arc Welding (SMAW) is the recommended approach for most.

- Interpass Temperature Control: The interpass temperature should be constant over a period of time to mitigate the chances of rapid cooling. If not monitored closely, brittle cracks can result.

- Post-Weld Heat Treatment: After welding, stress relief will be paramount. This heat treatment involves heating the spring to a temperature optimal for restoring mechanical properties and residual stress before allowing the piece to cool slowly.

From diligent preparation to the post-weld treatment, each step is equally important in achieving the ultimate goal, which is successfully welded 65mn spring steel. But remember, it is critical to confirm the structural soundness before proceeding to the final stage.

Challenges in Welding High Carbon Steels

The combination and the mechanical properties of high carbon steels make welding an intricate procedure due to the following problems:

- Cracking Susceptibility: The combination and mechanical properties of high-carbon steels make welding an intricate procedure due to the following problems: Proper preheat, along with interpass temperature control, is vital for lowering these changing risks.

- Heat-Affected Zone (HAZ) Hardening: Higher levels of heat input during the weld can harden the Heat-Affected Zone and consequently increase brittleness while decreasing toughness. These issues can be reduced using proper heat input and other good weld parameters.

- Stress and Distortion: A higher level of carbon also means a greater degree of thermal stress, along with cooling and potential distortion after the weld has been completed. Some means of relief measures, such as stress relief heat treatment, will need to be employed.

- Limited Weldability:

- High-carbon steels tend to have a much lower degree of weldability than low- or medium-carbon steels.

- The use of low-hydrogen consumables such as E7018 electrodes, along with other suitable filler metals, helps ensure compatibility and strong weld joints.

- Technical Parameters:

- Preheat Temperature: This depends on the size and thickness of the steel but typically ranges from 250F to 400F (120C to 200C) to minimize thermal gradients.

- Interpass Temperature: It should be controlled at around 400F (200C). This helps decrease the rate of cracking while preventing too much cooling.

- Heat Input: For the heat input, it is necessary to control the heating so that excessive hardening of the HAZ is avoided. Ideal value ranges differ with the welding method, but the aim should always be to strike a balance between depth of penetration and cooling rates.

- Post-Weld Heat Treatment Temperature: Stress relief is performed between 1100F and 1200F (593C to 650C) with minimal compromise to the mechanical properties of the welds.

With these appropriate welding practices and parameters, high-carbon steels, such as 65mn, can achieve durable and structurally sound welds. Always check the procedure against the project to meet the specific project’s performance needs.

Techniques for Successful Welding

When welding high carbon steels, such as 65mn, my principal concern is choosing the correct filler, which should possess matching or slightly inferior characteristics than the base metal. I always use preheating as part of my process because it reduces the risk of cracking by controlling temperature fluctuations and thermal shocks. While welding, I also maintain the interpass temperature to a constant of about 200°C and carefully manage the heat input to ensure that the hardening in the heat-affected zone is not excessive. I use post-weld heat treatment between 593 and 650 degrees centigrade to relieve stress, which helps maintain the mechanical integrity. These procedures, which can vary depending on the specific project and thickness of the material, always result in strong, durable welds.

What are the Physical Properties of 65mn Steel?

65mn steel is a high-carbon, high-strength material with excellent wear resistance and toughness. It possesses physical properties like high tensile strength, good elasticity, and hardness, which can be further improved by quenching and tempering. With carbon content ranging between 0.62 to 0.70 percent and manganese content between 0.90 and 1.20 percent, it can perform well in most demanding applications. It has a density of approximately 7.85gcm³ and has good machinability when in the annealed state. These properties are ideal for tools, springs, and other wear-resistant components.

Examining the Density and Malleability

By examining the density of 65mn steel, it is found that its value is approximately 7.85 g/cm3, similar to many high-carbon steels. This density supplies the strength needed for heavy-duty applications. Regarding its malleability, 65mn steel has low malleability in its tempered and hardened state but significantly improves when annealed. It is versatile for making tools, blades, and firm spring parts through appropriate heat treatment to balance toughness and workability.

Understanding Corrosion Resistance in 65mn

Unlike high-carbon steels, the corrosion resistance of 65mn steel is moderate, which enables it to withstand more damage than other iron alloys. However, for the steel to not rust or deteriorate, it is put in water or humid areas and requires proper maintenance. To counter severe corrosion, this type of steel is oil-coated or treated by galvanization to withstand the environment better. In places of high moisture, these methods disallow oxidation to occur, improving the steel’s functionality. The protective treatment of 65mn steel is oil, untreated 65mn steel transforms undergoes standard corrosion that is common among high-carbon alloys when exposed to oxygen and water for a long time.

References

- 65Mn | 1065 | SUP6 | High Carbon Spring Steel – Provides details on the properties, wear resistance, and strength of 65Mn steel.

- Application Analysis of 65Mn Heat-treated Spring Steel Strip – Discusses various applications of 65Mn steel in automotive and industrial sectors.

- 65Mn Steel: Properties, Specifications, and Applications – Offers a comprehensive overview of the material’s properties and uses.

Frequently Asked Questions (FAQ)

Q: What is 65mn spring steel, and why is it popular?

A: 65mn spring steel is a high-carbon, manganese alloy known for its high strength and wear resistance. It is mainly used in applications requiring toughness and durability, such as coil springs, saw blades, and various machinery components.

Q: How does 65mn carbon steel compare to other carbon spring steels like 1095 and 1065?

A: 65mn carbon steel offers a balanced combination of hardness and toughness, making it suitable for applications with high strength and wear resistance. It is more challenging than 1095 and performs similarly to 1065, depending on the application requirements.

Q: What are the typical applications for 65mn steel plates?

A: 65mn steel plate is typically used in making cutting tools, saw blades, spring chucks, and other tools requiring high hardness and toughness. Its wear-resistant properties make it suitable for high-stress applications.

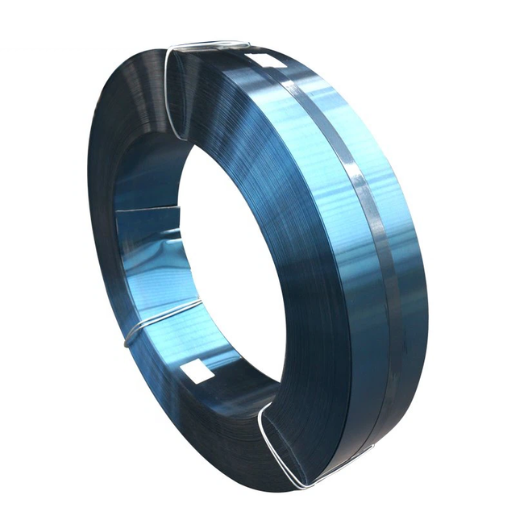

Q: Can you explain the product details for the 65mn steel coil?

A: 65mn steel coil is a high-strength, wear-resistant product available in various widths and thicknesses. Due to its excellent temper and durability, it is mainly used in the production of coil springs, spring rings, and spring plates.

Q: What are the benefits of using 65mn spring steel in coil springs?

A: Using 65mn spring steel in coil springs provides high strength, excellent fatigue resistance, and long-lasting performance. The manganese content enhances its wear resistance, making it ideal for demanding applications.

Q: How is 65mn carbon steel hardened and tempered?

A: 65mn carbon steel is typically hardened by heating to a specific temperature followed by quenching. It is then tempered to achieve the desired balance of hardness and toughness, making it suitable for high-performance applications.

Q: What standards and specifications does 65mn spring steel comply with?

A: 65mn spring steel complies with various standards and specifications, including ASTM and GB 1566, ensuring high-quality and consistent performance for industrial applications.

Q: Are there any specific suppliers for high-quality 65mn spring steel?

A: Several suppliers globally offer high-quality 65mn spring steel, providing products that meet industry standards for wear resistance, strength, and durability. Choosing a supplier with a proven track record for delivering consistent quality is advisable.

Q: In what forms is 65mn spring steel available?

A: 65mn spring steel is available in various forms, including steel sheets, plates, coils, and drawn steel wires. Each form is suited to different applications, from making coil springs to cutting tools and machinery components.

Q: How does the manganese content in 65mn alloy affect its properties?

A: The manganese content in the 65mn alloy enhances its strength and wear resistance. It also contributes to the steel’s hardness and toughness, making it suitable for high-stress applications such as machinery parts and cutting tools.