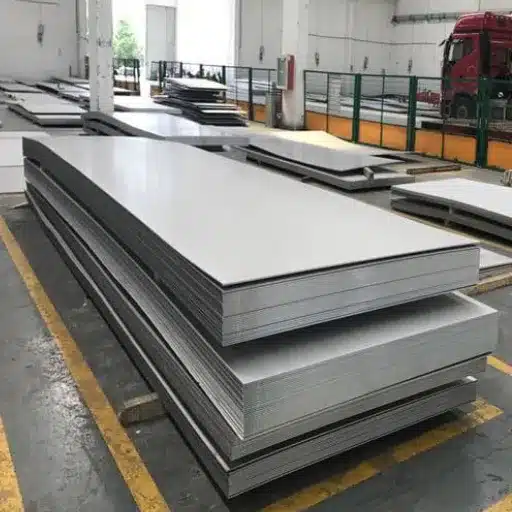

The 304 stainless steel sheet demonstrates higher strength and superior ability to withstand both physical pressure and operational requirements, which industrial and commercial projects demand. The stainless steel grade has gained widespread acceptance in various industrial fields because it provides exceptional protection against corrosion and maintains high strength while offering a visually appealing design. The primary reasons for using 304 stainless steel sheet in various applications remain a mystery. The article presents an analysis of the fundamental characteristics and functional uses of the material along with its distinct project advantages. The guidebook offers essential information about 304 stainless steel to manufacturers, designers, and engineers who want to understand why the material continues to be a popular choice for building projects.

Understanding 304 Stainless Steel Sheets

What is 304 Stainless Steel?

The 304 stainless steel alloy stands as the most adaptable stainless steel material that people throughout the world use. The metal exists as austenitic stainless steel, which demonstrates exceptional corrosion resistance together with high durability and easy production methods. The standard formula of 304 stainless steel consists of iron as its main element, together with 18-20% chromium and 8-10.5% nickel, which creates the common designation of “18/8 stainless steel.” The material provides complete protection through its chromium and nickel components, which defend against oxidation and rusting and chemical attacks, enabling different uses for the material.

The primary benefit of 304 stainless steel protects its structure from damage that occurs because of corrosion. The material displays exceptional performance capabilities when it must endure extreme test conditions that involve both chemical exposure and testing with acidic materials and saltwater environments. The material enables 304 stainless steel to preserve its structural strength when exposed to temperatures that reach about 1,700°F (927°C) because it maintains its operational capacity during this temperature range.

The 304 stainless steel material demonstrates its mechanical properties through a tensile strength of 515 MPa (75 ksi) and a yield strength of 205 MPa (30 ksi). The material demonstrates excellent formability, which enables it to transform into different shapes through welding, machining and fabrication processes into sheets, tubes, and wires. This construction enables the product to function effectively in industrial environments and domestic spaces.

People use 304 stainless steel for various purposes, which include kitchen equipment like sinks and cookware, architectural designs, medical devices, and chemical processing machinery. The decorative visual appearance of 304 stainless steel, together with its simple maintenance requirements make it the preferred material for practical and decorative purposes.

Key Properties of 304 Stainless Steel Sheet

The different functions of 304 stainless steel sheet material function in various industrial applications because it displays outstanding physical characteristics. The material displays three basic properties, which represent its primary physical characteristics:

- Corrosion Resistance: The chromium content of 304 stainless steel exists between 18 and 20 percent, and its nickel content reaches 8 to 10.5 percent, which enables the material to protect against various corrosive environments. The material remains functional for indoor spaces and outdoor areas that experience moisture contact and chemical exposure.

- Strength and Durability: The material demonstrates high tensile strength, which reaches 505 MPa (73,200 psi) and yield strength at 215 MPa (31,200 psi) to maintain strength against extreme pressure conditions. The material maintains its structural integrity during its entire operational period, even in extreme working conditions.

- Temperature Resistance: The 304 stainless steel material operates at high temperatures, which reach 870°C (1598°F) for brief periods and 925°C (1697°F) for extended periods. The material suits applications with high-temperature requirements, which include heat exchangers and industrial ovens.

- Formability and Welding Capabilities: 304 stainless steel sheet allows various metal forming methods, which include deep drawing and bending, and roll forming. The material provides excellent welding capability with standard fusion and resistance welding techniques, which do not need post-weld annealing for most applications.

- Hygienic and Aesthetic Appeal: The material has a smooth surface finish, which prevents stains and enables fast cleaning, making it suitable for food handling and medical instruments, and any application that needs to meet hygiene standards.

- Density and Weight: Structural engineers can use 304 stainless steel, which has a density of 8.00 g/cm³, to create equipment and structural designs because this material allows weight reduction without compromising structural strength.

The properties of 304 stainless steel sheet create a reliable solution that needs few repairs and operates efficiently in different environments that range from industrial production facilities to architectural spaces in buildings.

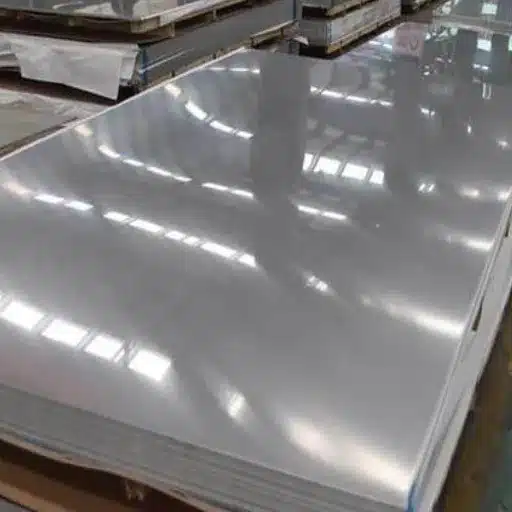

304 Stainless Steel Sheet Finishes: 2B vs Brush

The selection process for a 304 stainless steel sheet requires evaluation of the finish type because it dictates both surface appearance and performance capabilities across different settings. The following section provides an extensive analysis of the 2B finish and the brushed finish:

2B Finish: The 2B finish creates a polished surface that reflects light through factory processes that begin with cold rolling and finish through annealing and descaling. This finish provides excellent resistance to corrosion, which makes it a popular choice in applications such as chemical processing equipment and pharmaceutical machinery, and kitchen appliances. According to updated industry data, the 2B finish maintains an average surface roughness (Ra) between 0.1 and 0.5 µm, which results in easy maintenance and hygienic design.

Brushed Finish: The brushed finish creates a visually appealing surface through a mechanical polishing method, which produces an engineered directional pattern. The 2B finish provides functional benefits through its higher corrosion resistance, which results from its smooth surface texture. This finish is widely used in architectural design for both interior and exterior spaces, which includes elevator panels and decorative hardware. Brushed stainless steel displays a surface roughness (Ra) that ranges between 0.6 and 1.2 µm, which decreases mirror-like reflection but makes the material appropriate for design-oriented purposes.

Performance Comparison:

- Appearance:

- 2B Finish: The surface has a smooth reflective design that fits either functional needs or hidden operational components.

- Brushed Finish: The surface has a matte finish, which shows directional lines, making it suitable for use in decorative applications.

- Corrosion Resistance:

- The 2B Finish has higher protection against corrosion because its surface remains smooth.

- Brushed Finish requires careful cleaning to maintain performance in corrosive environments.

- Applications:

- The technical and hygienic applications of 2B Finish use this finish as their standard.

- Brushed Finish is preferred for aesthetics in visible installations.

The selection of an appropriate finish depends on project needs because both finishes deliver distinct benefits.

Applications of 304 Stainless Steel Sheet

Industrial Applications of 304 Stainless Steel

The industrial applications of 304 stainless steel achieve excellent results because its materials provide superior metal protection and structural strength, and ease of production. The material is widely used in the industry, according to recent research and industrial data, which shows its current applications.

- Chemical Processing: 304 stainless steel is used extensively in chemical plants for manufacturing equipment such as tanks, piping, and heat exchangers. The material demonstrates exceptional performance because it can withstand all types of corrosive chemical substances that include both acids and alkalis. According to recent reports, the global demand for stainless steel in chemical processing is projected to rise by 4.5% annually through 2030.

- Food and Beverage Industry: 304 stainless steel provides smooth and hygienic characteristics, which make it suitable for food-grade use in processing equipment and containers and kitchen utensils. Studies indicate that approximately 70% of food processing facilities worldwide rely on 304 stainless steel for sanitary production lines.

- Pharmaceutical and Medical: The manufacturing of medical devices, surgical instruments, and pharmaceutical equipment uses 304 stainless steel because it resists corrosion and does not react with other materials. The global stainless steel medical device market was valued at $6.8 billion in 2022 and is expected to grow steadily by 5.7% each year.

- Water Treatment Plants: 304 stainless steel is trusted in desalination plants, water pipelines, and wastewater treatment systems because it does not rust and can endure contact with water for extended periods.

The figures show that 304 stainless steel serves as an essential material that enables major industries to operate consistently over time.

Common Uses in Construction and Manufacturing

The construction and manufacturing industries depend on 304 stainless steel because of its ability to withstand various conditions while maintaining its functionality and resistance against corrosion. The construction sector worldwide needs stainless steel because urban building projects and environmentally friendly construction methods will drive its development, according to industry research. The outstanding oxidation and corrosion resistance of 304 stainless steel makes it the preferred material for architectural uses, which include structural elements, building exteriors, and roofs. It serves essential functions in worldwide famous buildings and architectural designs, which need to maintain their strength and visual beauty throughout time.

The manufacturing sector uses 304 stainless steel to create machines, automotive parts, and industrial equipment. Market reports confirm that global stainless steel demand for manufacturing will increase at a rate of 6% every year because of automation and renewable energy developments, and medical device manufacturing progress. The material provides necessary properties for multiple industries because it can be machined, and it maintains its structural strength under extreme stresses and high temperature conditions.

The Role of 304 Stainless Steel Sheet in Electrical Applications

The electrical industry uses 304 stainless steel sheets because they provide excellent protection against corrosion, long-lasting durability, and their ability to conduct heat. Engineers select this steel grade for designing electrical equipment because it enables systems to work properly under both extreme heat and extreme cold environmental conditions.

The latest data indicates that the global market for stainless steel sheets, which manufacturers use in electrical products, will experience demand growth at a rate of 5.8 percent every year until 2030. The demand for high-performance materials exists because renewable energy systems require these materials to construct dependable electrical systems that use solar and wind power generation technologies. The demand for stainless steel used in battery housings and motor components will increase as more vehicles become electrified.

The electrical system components that use 304 stainless steel benefit from its excellent conductivity and oxidation resistance because these properties make the material suitable for busbars and connectors. Manufacturers can achieve high functional performance through their lightweight design and simple manufacturing process, which enables them to create optimal product designs.

Comparing Stainless Steel Grades

304 vs Other Stainless Steel Grades

The evaluation of 304 stainless steel performance against other stainless steel grades requires assessment of its material composition, together with its mechanical characteristics and suitable usage scenarios.

- Chemical Composition

The composition of 304 stainless steel includes 18-20% chromium and 8-10.5% nickel, which provides the material with strong resistance against corrosion while maintaining its structural strength. The 316 stainless steel grade includes 2-3% molybdenum, which provides improved resistance against corrosion, especially in environments with high chloride concentrations. 430 stainless steel belongs to the ferritic stainless steel category, which contains minimal nickel content that results in lower manufacturing costs but reduces its ability to withstand certain corrosive environments. - Tensile Strength and Durability

The tensile strength of 304 stainless steel typically ranges from 515 MPa to 750 MPa. 316 stainless steel shows the same tensile performance as other materials, yet demonstrates increased protection against stress corrosion cracking under severe conditions. 430 steel provides sufficient performance for decorative functions but shows restricted capability to bend and withstand impacts. - Applications and Suitability

Due to its multiple applications, 304 stainless steel has become a standard material for industrial use. Its applications extend to kitchen tools, medical devices, and building materials. 316 stainless steel provides better protection against marine environments and chemical processing operations because of its molybdenum content. 430 stainless steel serves as an economical solution for equipment used in settings with minimal exposure to corrosion. - Cost Comparison

Price-wise, 304 stainless steel costs less than 316 stainless steel but exceeds the price of 430 stainless steel. Performance needs and financial limitations determine the selection process between the two options. 316 stainless steel costs 20-30% more than 304 stainless steel because it contains molybdenum.

Key Data Insights

- Corrosion Resistance: 316 > 304 > 430

- Cost Efficiency: 430 > 304 > 316

- Tensile Strength: 304 ≈ 316 > 430

- Versatility: 304 stainless steel serves as the most widely used material, which provides balanced performance for various industrial applications.

The selection process for stainless steel grades needs an understanding of specific comparisons between different grades, which enables industrial organizations to achieve their cost-effective and durable operational requirements.

Advantages of Choosing 304 Stainless Steel Sheet

The distinct features of 304 stainless steel make it the most commonly used stainless steel alloy across different industrial sectors. The subsequent sections show the system advantages that it provides.

- Corrosion Resistance: The industrial and coastal and slightly acidic environments present superior oxidation and corrosion protection which 304 stainless steel provides. The material prevents rust formation during both indoor and outdoor use.

- Durability and Strength: The tensile strength of 304 stainless steel reaches 505 MPa (73,200 psi), which allows the material to maintain its strength and durability. The material can sustain tensile loads without developing cracks, and it functions effectively in temperatures that reach up to 870°C (1598°F).

- Cost-Effectiveness: The 304 stainless steel grade provides a budget-friendly option that meets strength and corrosion resistance requirements for standard applications.

- Ease of Fabrication: 304 stainless steel can be easily welded and formed, which makes it suitable for multiple manufacturing operations that include cutting, bending, and welding. The material provides excellent machinability while its mechanical properties retain their initial state.

- Food-Grade Safe: The non-toxic and hygienic characteristics of 304 stainless steel make it suitable for use in both food processing facilities and medical equipment. The material meets NSF and FDA standards because it protects against contamination and allows for simple cleaning procedures.

- Aesthetic Appeal: 304 stainless steel has a smooth, shiny finish, which makes it the preferred material for architectural and decorative applications. The material maintains its original appearance throughout extended periods of various environmental conditions, which makes it more attractive to users.

- Sustainability: The complete recyclability of 304 stainless steel results in decreased environmental damage. The material functions as an environmentally sustainable solution that helps industrial sectors achieve their green objectives.

The construction industry, automotive sector, medical field, and food processing industry can utilize 304 stainless steel sheets to gain performance advantages, which result in long-term operational efficiency and asset protection.

When to Choose 304 Stainless Steel Plate

304 stainless steel plate provides an ideal solution for people who seek to accomplish their needs because it combines multiple applications through its exceptional ability to withstand corrosion while delivering enduring performance at affordable prices. The following list provides examples of situations where 304 stainless steel plate stands out as the best material solution.

- High Corrosion Resistance Needs

304 stainless steel plate demonstrates exceptional corrosion protection, which extends to most outdoor environments and light exposure to chemical substances. This makes it an ideal choice for industries like food processing and chemical manufacturing. The material demonstrates high reliability in high-temperature operations because it maintains oxidation resistance at temperatures up to 1,500°F. - Hygienic Applications

The non-porous surface of 304 stainless steel meets strict hygiene standards, which makes it the preferred material for medical instruments, kitchen equipment, and food-grade manufacturing. Reports indicate that over 50% of global stainless steel production is directed to industries requiring sanitary conditions, with Type 304 being the most commonly used. - Aesthetic Appeal and Versatility

Architectural and decorative uses benefit from the shiny, polished surface of 304 stainless steel because it creates an attractive visual effect. The material shows design versatility because architects can use it for building facades and sculptures, and interior design through different finishing methods, which include satin finishing and mirror polishing. - Sustainability and Environmental Goals

According to global metal recycling industry data, 304 stainless steel has a complete recycling capability, with more than 80 percent of its material being recycled. The material becomes sustainable because it supports businesses that want to use environmentally friendly methods or achieve green certification. - Cost-Effectiveness for General Applications

The material selection for 304 stainless steel remains a budget-friendly option when customers need strong materials that do not require additional expenditures. The current market data shows that 304 stainless steel maintains its position as one of the most affordable stainless materials that industries use to maintain product quality while managing their financial resources.

The key attributes that industry data supports allow businesses to select 304 stainless steel plate as their ideal material solution for multiple applications that require an adaptable, sanitary, and environmentally friendly material solution that achieves consistent performance.

Maintenance and Care for 304 Stainless Steel Sheets

Cleaning Techniques for Stainless Steel Sheet 304

The maintenance process for 304 stainless steel sheets requires proper cleaning methods because those methods protect the material from damage and maintain its aesthetic appeal. The material lifespan extends when people conduct regular maintenance because it keeps their environment clean. The cleaning process begins when users use a soft cloth or microfiber towel to wipe surfaces after they have prepared the towel with warm water and mild detergent. The method effectively removes all standard dirt and grease, together with fingerprints. Users need to keep the protective layer on the surface because they should not use any type of abrasive cleaners or scrubbers.

The current industry standards recommend cleaning solutions that have a pH level between 6 and 8 because these levels protect against corrosion and discoloration. The user should apply a diluted vinegar solution to remove tough stains, which should be followed by complete water rinsing and drying with a clean cloth to stop water stain formation.

People can achieve safe and effective results when they use commercial stainless steel cleaners or polishes that manufacturers create specifically for grade 304 stainless steel to eliminate rust and tough stains. The polishes contain special additives that improve the material’s anti-corrosive properties to ensure protection during extended use. Search data also shows that more than 85% of users choose non-abrasive specialized cleaning products because they want to keep their stainless steel equipment both clean and visually appealing.

Businesses operating in industrial environments need to create maintenance plans that include regular maintenance as well as protective equipment usage because these practices reduce damage from extreme weather. The cleaning methods that businesses and individuals use will maintain their 304 stainless steel sheets in pristine condition while their sheets achieve peak operational efficiency.

Preventing Corrosion in 304 Stainless Steel

The 304 stainless steel protection against corrosion needs multiple protective systems because its exposed areas are vulnerable to both physical damage and chemical attacks. The latest data shows that these three preventive measures provide the highest effectiveness:

- Proper Cleaning and Maintenance

The cleaning process needs to happen at regular intervals through the use of non-abrasive mild cleaning products, which must be used to eliminate pollutants, which include chloride residues that cause pitting corrosion. The standard choice for cleaning should become chloride-free cleaners because chloride compounds present the greatest danger of localized corrosion problems on stainless steel. - Environmental Control

People must avoid entering areas that contain marine ecosystems and locations that have extreme humidity and salt exposure because these environments contain highly corrosive materials that can cause corrosion. Protective coatings offer defense against two types of environmental threats, which include moisture and hazardous atmospheric chemicals. - Passivation Treatments

The process of passivation treatments creates an oxide layer that protects 304 stainless steel surfaces from corrosion. The research in the industry shows that stainless steel lifespans increase by 20-30% when users conduct passivation treatment at regular intervals during extreme weather conditions. - Avoiding Cross-Contamination

The process requires stainless steel handling to maintain tools and materials in a state of cleanliness, which should exclude any corrosive materials. Rusting occurs at an accelerated rate when carbon steel cross-contamination transfers particles to other materials. - Monitoring pH Levels

The research shows that cleaning processes and environmental conditions need to maintain pH levels at neutral, which exists between 6 and 8. The material experiences accelerated deterioration when it is exposed to highly acidic or highly alkaline environments.

The implementation of these strategies results in reduced corrosion rates, which help to achieve maximum durability for 304 stainless steel. The 2023 research findings show that these practices from industrial experts lead to longer operational periods while reducing maintenance costs in commercial and industrial settings.

Long-term Care Tips for 304 Stainless Steel Sheets

The 304 stainless steel sheets need appropriate maintenance methods that help them reach their optimal strength and maintain their built-in beauty until the end of their operational life. The following tips provide complete guidance through their detailed explanations, which include current informational insights.

- Regular Cleaning and Maintenance

The surface needs cleaning every day because mild soap and warm water, together with a soft material, should be used to remove all dirt and grease, and other materials that contaminate the surface. The use of abrasive cleaners or steel brushes should be avoided because these products will create surface scratches that damage the corrosion-resistant layer. A 2023 industry report shows that routine maintenance enables users to extend the lifespan of stainless steel surfaces by up to 30%. - Preventing Surface Corrosion

The 304 stainless steel material maintains its high resistance to corrosion, but stagnant water and crevice spaces create significant security threats. The areas where water and debris collect must be inspected regularly because these sites become hazardous during humid weather. Research shows that wiping stainless steel surfaces after they contact high moisture levels decreases corrosion risk by 25%. - Use of Protective Coatings

The application of a specialized stainless steel coating provides advanced protection against both stains and corrosion. The coatings that are easily accessible to customers include fluoropolymer and nano-ceramic agents, which create protective barriers that prevent damage from severe environmental conditions. The coatings deliver efficient protection for both coastal areas and industrial locations that experience elevated levels of airborne pollutants. - Avoiding Contact with Chlorides

Salt, cleaning agents, and seawater all contain chloride ions, which create long-term damage to stainless steel. The operator must clean the contaminated area right away and conduct a follow-up rinse. A 2023 study found that industries that used anti-chloride protective sprays achieved a 40% reduction in pitting corrosion on their stainless steel surfaces. - Temperature Management

The 304 stainless steel sheets should not experience exposure to extreme heat or temperature changes because these conditions will cause thermal fatigue and discoloration over time. The material maintains its best performance until 1400°F according to ASTM standards but surface temperatures should be kept low to enhance material durability. - Polishing and Restoring Shine

Stainless steel sheets need periodic polishing with stainless steel-specific polish to sustain their visual appeal throughout time. The process renews the material’s original brightness while it enhances the material’s surface protection.

The long-term care tips will help maintain both the performance and appearance of 304 stainless steel sheets, which will enable them to serve their functional and decorative purposes for many years ahead. The basic principle for achieving permanent results in industrial manufacturing, architectural design, and home usage lies in maintaining consistent equipment maintenance and implementing preventive measures.

Reference Sources

-

Analysis of the formability of AISI 304 steel sheets with different gauges

This work analyzes the formability of AISI 304 steel sheets with varying thicknesses, providing insights into their applications.

Source: Redalyc -

Superior Strength and Ductility of 304 Austenitic Stainless Steel

This study highlights the mechanical properties of 304 stainless steel, focusing on its superior strength and ductility due to gradient nanograins.

Source: PubMed Central (PMC)

Frequently Asked Questions (FAQs)

What Are the Key Properties of 304 Stainless Steel Sheets?

The value of 304 stainless steel sheets exists because they can withstand corrosion, and they have permanent durability, and they display exceptional strength. The sheets contain chromium and nickel as their main components, which enable them to protect against rust and oxidation in different environmental conditions. The sheets possess a beautiful surface that enables their transformation into multiple shapes, making them appropriate for both functional applications and aesthetic purposes.

Where Are 304 Stainless Steel Sheets Commonly Used?

The widespread use of 304 stainless steel sheets throughout different industrial sectors results from their capacity to adapt to various applications. The materials find applications in multiple fields, which include household appliances and architectural design, industrial manufacturing, and food processing equipment. The materials’ non-reactive properties make them popular for kitchen surfaces and sinks, and utensils.

How Do I Maintain 304 Stainless Steel Sheets for Long-Term Durability?

The maintenance of 304 stainless steel sheets requires proper maintenance practices to preserve their operational functions and visual characteristics. The sheets need to be cleaned through regular washing with mild detergents and water, which helps to stop dirt and grime from accumulating. The use of abrasive cleaners should be avoided because they can damage the surface through scratching. The process of polishing the material helps to restore its original shine while also strengthening the protective coating, which results in a longer lifespan for the sheet.

What Are the Advantages of Using 304 Stainless Steel Sheets for Construction Projects?

The construction industry uses 304 stainless steel sheets as a preferred material because they maintain their strength under extreme weather conditions and corrosive environments. The materials possess lightweight characteristics together with high strength, which enables them to maintain their structural integrity during use. The combination of their contemporary design and their resistance to wear enables buildings to achieve both visual appeal and extended operational lifespan.

How Does 304 Stainless Steel Compare to Other Stainless Steel Grades?

The properties of 304 stainless steel lead to its widespread use because it offers both affordable pricing and protection against corrosion and straightforward handling. The superior properties of 316 stainless steel make it the best material choice because it withstands both chlorides and dangerous chemicals, which makes it suitable for use in marine environments and extreme corrosion zones. The most common applications require 304 stainless steel as the ideal material choice.