The success of your projects depends on the reliable and premium-grade supplier of stainless steel forging. Due to its excellent mechanical and physical attributes, durability, and resistance to corrosion, stainless steel forgings are invaluable in the automotive, aerospace, construction, and energy industries. At the end of this article, you will be fully informed on finding the right supplier to suit your unique needs. In this blog post, you will understand the importance of stainless steel forgings, key elements to consider when choosing a supplier, and a summary of the best custom stainless steel forgings manufacturers.

What Are the Leading Stainless Steel Forging Suppliers in the Industry?

Sitting on the top tier of industry stainless steel forging suppliers due to their experience, prowess, and customization capabilities are:

- Scot Forge—Scot Forge has built an industry-wide reputation for customer satisfaction, aided by its high-quality stainless steel forgings. Scot Forge specializes in the aerospace, defense, and energy industries and provides customized components.

- ATI Forged Products—ATI remains a household name in the forged products sector. It is well-known for its innovation and advanced technology, offering durable and strong stainless steel forgings.

- FRISA—Having carved a niche in the precision manufacturing arena, FRISA has grown to be a world leader with the range of forged solutions it provides across the automotive, oil and gas, and power generation industries.

- Weldaloy Products Company—Weldaloy has established a name for craftsmanship in open and closed die forgings, producing high-performance stainless steel components.

- Precision Castparts Corp. (PCC)—PCC’s substantial global network allows it to specialize in the manufacturing of high-quality, large-scale forgings for industry and aerospace customers.

Each of these suppliers is renowned for excellence, making them key players in the stainless steel forging industry. When choosing suppliers, factors like production capabilities, certification requirements, and their ability to provide custom solutions should be checked.

Evaluating Forging Manufacturers Based on Forging Capabilities

While gauging potential forging vendors, I emphasize their capabilities: what kind of materials they work with and the scale and detail of forgings they can manufacture. Likewise, certifications are essential because they tell us how these vendors qualify for industry and regulatory standards and quality control procedures. Also, I pay more attention to suppliers who are willing to develop complex designs with a proven history of serving demanding industries like aerospace or power generation. This is complemented by an extensive analysis of clients’ testimonials, case studies, and relevant technical information available on trustworthy portals.

Custom Forged Products from Premium Suppliers in the USA

There are essential factors to remember when purchasing custom-forged products from elite providers based in the USA. Such factors include:

- Material Compatibility

Check whether the supplier has the requisite materials as per their application needs. Some of the most frequently used materials are:

- Carbon Steel, ASTM A105

- Stainless Steel 304 and 316

- Alloy Steel AISI 4140 and 4340

- Inconel and Hastelloy High-Temperaturerestrictions Alloys

- Manufacturing Standards & Certifications

Ensure that the supplier conforms to known industrial requirements and is certified for:

- Quality Management ISO 9001

- Production restrictionswhen purchasing custom-forged under ASTM and ASME

- API approval for energy industry usage where necessary

- Dimensional Precision

Check whether the supplier is capable of delivering required project dimensions along with the needed tolerances, including, but not limited to:

- Diameter: 120 inches max

- Weight: 1 lb min, 50,000 lbs max (depends on use)

- Tolerances: ±0.005 inches (critical parts)

- Mechanical Properties

Acquired products should correspond with the set targets, including:

- Tensile strength: specific steel grades reach up to 100 ksi

- Yield strength, sometimes up to 70 ksi

- Dependent on the use case hardness level of Rockwell/BrinellHigh-Temperature

- Delivery and Lead Times

Production lead time is essential. Depending on complexity, ensure the supplier can meet demands within 4-12 weeks. Urgent orders can receive more attention.

Analyzing supplier dependability, including material compatibility, technical attributes, certifications, and other vital factors, gives you the information to guarantee product quality and performance, matching essential features for aerospace, energy, construction, transportation, and many more sectors.

Contact Us to Connect with Reliable Stainless Steel Forging Suppliers

We aim to meet your specific stainless steel forging needs by connecting you to reputable suppliers. We guarantee quality, timely delivery, and technical excellence, so you can trust that every component will be durable and engineered with precision. Reach out today to discuss your needs and learn how we can help you with dependable forging services for your projects.

How to Choose the Right Stainless Steel Grades for Your Forging Needs?

While determining the stainless steel grades for your forging projects, it is essential to consider the application, environment, and mechanical needs. For instance, 304 marine and chemical environment grade and 316 grade are ideal for areas that require corrosion resistance. However, increases in strength and wear-resistant materials grade 410 and 420 are more suitable for tool and machinery components. Ensure you evaluate the finishing processes, stress ranges, and temperature cycles to select the grade that will provide optimal value and longevity. A reliable forging supplier can assist you in making proper choices as well.

Austenitic Stainless Steel vs Duplex Stainless Steel for Forgings

Both duplex stainless steel and austenitic stainless steel are beneficial for forge work, but each has particular characteristics that make them suitable for different types of projects. The austenitic stainless steels, mainly the 304 and 316 grades, have good corrosion resistance, high formability, and are non-magnetic. These are ideal for applications subjected to very low or high temperatures and harsh chemicals, including food, chemical processing, and marine applications. Their chromium content is typically around 16-26%, and nickel is at about 8-10%, which accounts for their high oxidation and scaling resistance.

Unlike austenitic ones, the duplex stainless steels, such as grade 2205 and 2507, have ferritic components. They have high strength and low density and almost double the yield strength of austenitic steels. The duplex steels are also highly resistant to pitting, stress corrosion cracking, and crevice corrosion in chloride-bearing environments, making these steels ideal for oil and gas, chemical, and desalination industries. The composition of Duplex stainless steels is chromium content of about 20 to 25 percent, molybdenum 3 to 4 percent, and nickel 5 to 7 percent.

Technical comparison summary:

- Corrosion resistance:

- Austenitic: Extreme, however less in chloride (PREN ~ 18-26).

- Duplex: Most favorable in settings with high amounts of chlorides present due to higher PREN values (30-40).

- Strength:

- Austenitic: Lower yield strength (~200-300 MPa).

- Duplex: Greater yield strength (~450-600 MPa) permits weight savings in the designs.

- Temperature Range:

- Austenitic: Functions well in frigid and hot temperatures (-196°C to 870°C).

- Duplex: Less high-temperature performance (suggested to be used below 300°C).

- Weldability:

- Austenitic: Outstanding, though you must be careful as thermal cracking may occur.

- Duplex: Good, but phase imbalance must be controlled much more.

When making a choice for either one, consider the particular operational conditions, such as the corrosive atmosphere, necessary mechanical strength, or thermal requirements. For example, austenitic stainless steel performs better at elevated temperatures where there are no aggressive conditions, whereas duplex stainless steel is better for use in very demanding conditions with high-strength chlorides. Always check with material and forging technologists to confirm that the selected materials would meet the project requirements.

Understanding Stainless Steel Alloys and Their Applications

In my work, a more prominent identification feature is under as-level candidates class A, as I focus on gap matching position to arrest type. I prefer using austenitic stainless steel for areas under high temperatures due to its excellent formability and heat resistance. When I have a task set with a corrosive atmosphere and strong aerosols rich in chlorides, I often view duplex stainless steel as an attractive option as it features increased strength and enhanced resistance to corrosion. To achieve the best results, it makes sense for me as a designer to contact alloy experts and project engineers. They will help determine the right mechanorrhadic, thermal, and outer aid specs for which the alloy is needed.

Corrosion Resistance Properties of Different Forged Stainless Steel Alloys

I consider various factors when deciding which stainless steel alloy to use, especially ones pertaining to corrosion resistance. As such, austenitic stainless steels such as 304 and 316 are ideal for general corrosion resistance, 316 being the best due to their added molybdenum content that further protects against pitting and crevice corrosion in areas rich in chlorides. Ferritic stainless steels such as 430 have moderate corrosion resistance and are economical, making them ideal for less harsh environments. Duplex stainless steels such as 2205 excel in withstanding stress corrosion cracking and are effective in very corrosive environments due to having a dual-phase structure. My decision is guided by the concrete application ,the surrounding environment, and the economic effectiveness of the alloy so that the best results are achieved.

What Are the Different Stainless Steel Forging Processes and Services Available?

While numerous forged stainless steel products and services exist, each service is tailored to address specific requests and details. Standard offerings include open-die forging, where hammering shapes significant components without a surrounding die, and closed-die forging, which utilizes custom-shaped dies to create complex and precise parts. Also, rolled ring forging is performed to manufacture seamless rings known for their strength and durability. The forged components are further enhanced with heat treatment, surface finishing, and machining. The most cost-effective combination of services and processes is chosen, extracting the requested properties and application constraints.

Open Die Forging vs Closed Die Forging: Which Process Is Right for You?

When comparing closed-die forging with open-die forging, it largely depends on the complexity of the shape, material usage, and budget costs.

Open Die Forging is appropriate for significant, low-complexity components with high-quality mechanical properties. This process is more flexible because the dies do not completely enclose the material, making it easier for low-volume and custom orders. Here are some essential details:

- Size Range: Large components can be produced (in several tons).

- Material Waste: Waste is low since the material is not bound.

- Precision: Lower than closed die forging, thus more machining operation at the end is required.

- Applications: Commonly for shafts, rollers, and structural parts in heavy industries.

Closed Die Forging is ideal for intricate designs as well as bulk production. Closed dies allow for better tolerances and more complex shapes as the material is completely enclosed in the dies. Here are some essential details:

- Size Range: Usually smaller to medium-sized components.

- Material Waste: Larger, as flash is usually needed.

- Precision and Complexity: High, with fine detailing and minimal machining process afterward.

- Applications: Widely applied to automotive components, tools, and aircraft parts.

The culmination of these decisions hinges on your requirements, which may include feature size, tolerances, production quantities, and even budgetary concerns. For large and simpler elements, open-die forging is the most economical process; however, for smaller and more intricate components, closed-die forging is more suitable.

Hot Forging Techniques for Stainless Steel Components

In hot forging, stainless steel is heated to a metal temperature above recrystallization, estimated to be between 1,900 to 2,400 Fahrenheit (1,038 degrees Celsius to 1,315 degrees Celsius). This enables the stainless steel to become more pliable, allowing for more intricate parts to be manufactured without losing the physical strength and toughness of the material. Primary hot forging techniques comprise of the following:

- Press Forging gradually applies slow and continuous pressure to the metal parts, which in turn produces more parts with extremely tight tolerances and desired shapes.

- Hammer Forging: Metal is worked by repeatedly applying high pressure against the workpiece at a specific angle. It is more suited for simplified shapes and large-scale production.

- Drop Forging: The aim of drop forging is to achieve the desired shape with minimum waste. This can be achieved by stamping the metal portion using closed dies.

Technical Parameters:

- Parameters of hot forging material temperature

- The range of temperatures used to heat stainless steel during hot forging is expected to be 1900 to 2400 Fahrenheit (1038 degrees to 1350 degrees Celsius).

- The best range will depend on the type of stainless steel (for instance, either austenitic or martensitic).

- Forging Pressure:

- It has an average of 800 to 2,500 primary tons and is set depending on the part’s size and degree of intricacy.

- Cooling Rate:

- Stainless steel is simply air-cooled; otherwise, if cooled in water, the part should be swathed in cloth to prevent cracking or warping.

- Surface Finish:

- After forging, parts should be cleaned, possibly by picking or grinding, to remove the scale that forms during high-temperature forging.

Hot forging maintains the exceptional mechanical properties of stainless steel components, including high tensile strength and resistance to corrosion. It is commonly used in manufacturing to produce valve housings, flanges, and medical-grade instruments.

Rolled Ring and Disc Forging Services for Industrial Applications

We provide rolled ring and disc forging services to a range of industrial sectors. Employing innovative forging methods, we create precision components that are strong, accurately sized, and can withstand harsh environments. All our clients in the aerospace, automotive, oil and gas, and power generation industries receive unique solutions for each product without compromising on industry standards. Through our exceptional forging processes, we guarantee outstanding power for critical applications for high-performance bearings, custom industrial parts, gear blanks, and more.

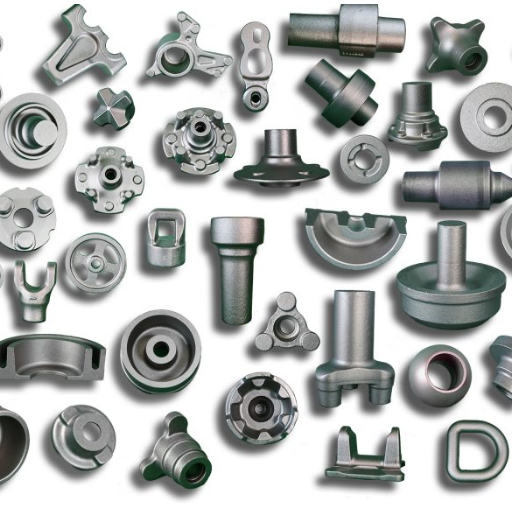

What Products Can Be Made Through Stainless Steel Forging?

Stainless steel forges work on an extensive range of items in various industries. These include but are not limited to, flanges, shafts, valves, fittings, rings, and gears that must possess great strength and accuracy. Besides, aerospace parts, automotive components, industrial machinery parts, and tools are brain high-performance components. These products harness marketing forged components’ strength, durability, corrosion resistance, and reliability.

Custom Stainless Steel Forgings for Fittings and Flanges

Our company’s core competence is designing, producing, and supplying stainless steel precision forgings for fittings and flanges of diverse industries. We use modern forged to attain every product’s needed strength, precision, and super durability. Our capabilities include outperforming custom design solutions and applying stainless steel’s unparalleled corrosion resistance and reliability in harsh working environments. We pay close attention to our customers, whether they ask for custom design or highly specialized components.

Forged Shafts and Components for Power Generation

Forged shafts and components are critical in power generation because of their unrivaled performance and dependability in high-stress situations. These components must endure high temperatures, heavy loads, and constant usage. Forging helps the parts achieve better mechanical properties and endurance through superior grain alignment.

Carbon steel, alloy steel, stainless steel, and other heat-resistant alloys are the key materials constituting forged shafts. These materials were chosen due to their strength, corrosion resistance, and aptitude for working under harsh conditions. Standard uses include turbine rotor shafts, generator shafts, and pump shafts.

Technical Parameters:

- Material Strength: The yield strength is estimated to be between 250 MPa and 600 MPa, depending on the alloy and application.

- Dimensional Tolerances: ±0.01 mm is the tolerable margin from the desired measurement due to precision machining.

- Surface Hardness: Surface hardness received through heat treatment could reach 200 to 400 HB (Brinell Hardness).

- Diameter: Shafts customized in diameters from 30 mm to over 1200 mm are available for all equipment sizes.

- Length: Shafts can be manufactured as long as 10 meters for more significant applications.

This process also provides significant impact and fatigue resistance alongside intense strength, enabling these components to be used for turbines, generators, compressors, and other power equipment. The leading industry manufacturers allow users to alter forged shafts to their desired specifications, guaranteeing proper and reliable functionality in their operations.

Forged Stainless Steel Fluid Ends and Industrial Machinery Parts

Fluid ends used in pumps of hydraulic fracturing processes are of a high-grade forged stainless steel along with liquid pumped, and these components exceed expectations in terms of quality and performance while demonstrating impressive strength, high durability, and commendable corrosion resistance. They are most commonly used on pumps in pumping units, as reliability for these parts is vital and depends on severe conditions. A problematic environment doesn’t introduce challenges in the performance of heavy-duty oil and gas industrial equipment, mining, and manufacturing, which is achieved through heavy-duty forged industrial machinery parts. Strict industrial requirements are easily met with advanced techniques in foraging and improved efficiency in production processes.

What Are the Advantages of Forged Stainless Steel Over Other Manufacturing Methods?

Forged components outperform parts produced using casting or machining with superior resistance to impact and fatigue, making them perfect for high-stress applications. The effect of the forging process also offers enhanced mechanical properties and a strengthened grain structure. Another benefit of forged stainless steel is reliable performance, coupled with high corrosion resistance, even under severe conditions. Along with reduced maintenance costs, a longer service life is an impressive, cost-effective solution for many industries.

Comparing Forged Stainless Steel to Machined and Cast Components

About forged stainless steel and machined or cast components, these factors are strikingly different:

- Strength and Durability:

- Due to the component’s forging process, forged stainless steel has an exceptional grain structure, giving it greater tensile strength and fatigue resistance than machined and cast parts.

- Technical Parameter Example: The Forged stainless steel’s tensile strength in factors of the alloy ranges between 485 MPa and 600 MPa.

- Structural Integrity:

- Machined components frequently undergo cutting from billets and plate voids, while cast components are highly porous and may suffer shrinkage defects. These issues result in low structural integrity and weak reliability. Due to the defects removed from forgings, higher structural integrity is achieved.

- Corrosion Resistance:

- The increased densification of the material in cast components gives them surface micro cracks and impurities, so the more resistant material achieved during forging is better.

- Cost Effectiveness:

- The expense of tooling for forging starts off higher than for others, but the investment pays off as forged parts last longer and need less maintenance in the long run. Cast components may save initial money, but the frequent need to buy replacements later on significantly increases overall cost.

- Precision and Complexity

- Machined components’ manufacturing accuracy is ideal for complex shapes, albeit at the risk of wasteful material loss. Forging is best for producing high-strength parts with simpler geometric features, while casting copes better with complicated configurations, although the resulting pieces tend to be weaker.

Selection of production strategy according to technical specifications facilitates the optimization of performance, reliability, and costs simultaneously.

Enhanced Mechanical Properties of Die Forgings Made from Stainless Steel

The strength, durability, and corrosion resistance of freshly made stainless steel die designings give it an edge over others. In contrast to other manufacturing processes, die forging is known to modify the grain structure, increasing reliability and toughness during stress. Such a die-forging system is ideal for industries where mechanical features and performance constancy is crucial, such as aerospace or automotive. Furthermore, stainless steel’s extreme temperature and wear resistance make it a suitable option when the environment is harsh. This means that by utilizing die forging, I can create, with great precision, a component designed to exact specifications that will last a long time and is of superior quality.

How to Specify Requirements When Ordering Custom Stainless Steel Forgings?

Accurate and informative specifications must be given when ordering custom forgings made of stainless steel to achieve the desired end product. One of the primary factors to consider is the grade of stainless steel, desired mechanical properties, and industry regulations. Providing detailed drawings depicting dimensions, tolerances, and surface finish aids in the forging process. Also, stipulate the conditions of the application, such as pressure, corrosive, and temperature environments. Close cooperation with the manufacturer while further discussing quality control measures will include describing testing and inspection requirements to produce the most accurate and trusted stainless steel forgings.

Essential Information Your Forging Supplier Needs to Know

To make sure that accurate and high-quality forgings are done, it is essential to pass along the following information to your supplier:

- Material Specifications

- Materials types: Carbon steel, alloy steel, stainless steel, etc.

- Mechanical properties such as tensile strength, yield strength, and elongation.

- Heat treatment specs include annealing, normalizing, quenching, and tempering.

- Dimensional Specifications

- Dims and tolerances.

- Surface finish Ra value stipulations.

- Application-Specific Conditions

- Range of service temperatures; for example, minus twenty degrees centigrade to two hundred degrees centigrade.

- Pressure ratings such as one thousand psi and two hundred bar.

- Corrosive and high-wear condition exposure.

- Quality Standards and Certification

- Industry standard applicability includes ASTM, ASME, ISO, etc.

- Undercut inspection guidelines include ultrasonic and magnetic particle inspection.

- Mill test report and material certificate requirements.

- Quantity and Lead Time

- Batch quantity/size.

- Ordering delivery timelines and bounds.

When you define and communicate these parameters, you can produce forgings that are guaranteed to meet specified performance and reliability levels.

Understanding Tolerances and Surface Finish Requirements

While setting tolerances, I consider the forged parts’ functional and performance requirements, ensuring they correspond with the final application’s operational needs. I set clear dimensional tolerances, understanding that more precise tolerances could make production more complex and expensive. For the surface finish, I specify the roughness that would be most useful, and that would satisfy other design requirements. These details are essential to communicating so the forgings meet the quality and performance standards.

References

- IQS Directory – Stainless Steel Forgings Manufacturers and Companies: A comprehensive directory listing leading stainless steel forging companies like Ferralloy Inc., Anderson Shumaker, and Scot Forge.

- Great Lakes Forge – Stainless Steel Forgings: A detailed resource on high-grade stainless steel forgings provided by Great Lakes Forge.

- ThomasNet – Stainless Steel Forgings Suppliers: A platform offering precision forging services and supplier listings for various forging capabilities.

Frequently Asked Questions (FAQ)

Q: What are the key advantages of stainless steel forging over other manufacturing methods?

A: Stainless steel forging offers numerous advantages over other fabrication methods. The forging process creates components with superior strength, improved grain structure, and enhanced mechanical properties. Forged stainless steel products exhibit high strength, excellent heat resistance, and remarkable durability. Unlike welded components, forgings have no weak points and maintain structural integrity even under extreme conditions. Additionally, the forging process allows for near-net shapes, reducing material waste and machining costs. The protective oxide layer formed on stainless steel forgings provides exceptional corrosion resistance, making them ideal for demanding applications in oil and gas, marine environments, and chemical processing industries.

Q: How does the metal forging process improve the properties of stainless steel components?

A: The metal forging process fundamentally transforms the microstructure of stainless steel, resulting in significantly improved material properties. During forging, the material undergoes controlled deformation under pressure, which refines the grain structure and eliminates internal voids or porosity. This creates a more uniform and dense material compared to casting or machining. The directional alignment of the grain flow follows the contours of the part, enhancing its strength along stress lines. For stainless steel, forging preserves and optimizes its corrosion-resistant properties while increasing tensile strength, fatigue resistance, and impact toughness. The process also ensures better dimensional stability and consistent mechanical properties throughout the component.

Q: What should I consider when evaluating suppliers for my stainless steel forging needs?

A: Consider several critical factors when evaluating suppliers for your stainless steel forging needs. First, assess their technical capabilities, including their equipment range and ability to handle your specific grade of stainless steel. Examine their quality certification (ISO, AS9100) and inspection processes. Request material test reports and sample parts to verify quality. Evaluate their engineering support and design assistance capabilities. Review their experience in your industry and similar applications. Consider their capacity, lead times, and on-time delivery performance. Price is important but should be weighed against quality, reliability, and total cost of ownership. Finally, assess their willingness to form a strategic partnership rather than just being a transaction-based supplier, as this approach often yields better long-term results for complex stainless steel forgings.

Q: What are the advantages of working with forging companies made in the USA?

A: Working with USA-based forging companies offers distinct advantages. American manufacturers typically adhere to stringent quality standards and comply with domestic regulations. Communication is streamlined without language barriers or significant time zone differences, facilitating more effective collaboration on custom projects. Domestic suppliers generally offer shorter lead times and more responsive service than overseas. Transportation costs and import duties are eliminated, potentially offsetting higher labor costs. Intellectual property protection is typically stronger with domestic manufacturers. Additionally, many industries require domestic sourcing for critical components, and “Made in USA” forgings often come with full material traceability and certification. Domestic suppliers like Great Lakes Forge can provide more flexible order quantities and are better positioned to handle design modifications or urgent requirements.

Q: How does the die forging process differ from the open die forging process for stainless steel?

A: Impression die forging (closed-die) and open-die forging represent two distinct approaches to forging manufacturing, each with unique characteristics. In impression die forging, stainless steel is compressed between two dies containing a pre-cut cavity that shapes the metal into the final geometry. This process delivers tight tolerances, excellent surface finish, and complex geometries with minimal machining required. Conversely, open-die forging involves compressing material between flat or simply shaped dies, allowing the metal to flow freely in directions perpendicular to the force application. Open-die forgings are typically simpler shapes requiring more subsequent machining but can produce larger parts without size limitations imposed by die constraints. Die forgings generally offer better precision and material efficiency for moderate to high production volumes. In contrast, open-die forgings excel for very large components or low-volume production where die costs would be prohibitive.

Q: What industries benefit most from high-quality forged stainless steel components?

A: High-quality forged stainless steel components serve various industries that demand superior performance and reliability. The oil and gas sector relies on forged stainless parts for wellhead components, valve bodies, and pressure vessels due to their corrosion resistance and ability to withstand extreme pressures. The aerospace industry utilizes precision forging for critical components where failure is not an option. Chemical processing facilities benefit from stainless steel’s resistance to chemical attack and heat resistance. The food and pharmaceutical industries value the sanitary properties of forged stainless steel. Marine applications leverage its resistance to saltwater corrosion. Power generation, including nuclear and renewable energy, depends on forged stainless components for their durability and safety. Medical device manufacturers utilize the material’s biocompatibility and strength. The automotive sector, particularly for high-performance vehicles, employs forged stainless steel for superior strength-to-weight ratios in critical components.

Q: How does heat treatment affect the properties of stainless steel forgings?

A: Heat treatment plays a crucial role in enhancing and optimizing the properties of stainless steel forgings. Different heat treatment processes can dramatically alter forged stainless steel components’ mechanical properties, corrosion resistance, and microstructure. Solution annealing dissolves carbides and homogenizes the microstructure, maximizing corrosion resistance while relieving internal stresses from the forging process. Quenching and tempering can significantly increase hardness and strength in martensitic stainless steels. Precipitation hardening creates fine precipitates within the microstructure that obstruct dislocation movement, enhancing strength while maintaining good corrosion resistance. Age hardening can further improve mechanical properties for specific applications. The correct heat treatment process must be carefully selected based on the particular grade of stainless steel and the desired balance between strength, ductility, hardness, and corrosion resistance. An experienced forgings manufacturer will have expertise in determining the optimal heat treatment cycle for your specific application requirements.

Q: What are the typical lead times for custom stainless steel forgings, and how can they be optimized?

A: Lead times for custom stainless steel forgings typically range from 6-16 weeks, depending on complexity, size, and quantity. Several factors influence these timelines: design approval (1-2 weeks), die fabrication for new parts (3-8 weeks), material procurement (2-4 weeks), production scheduling (varies), forging operations (1-3 weeks), heat treatment (1-2 weeks), and final machining/testing (1-4 weeks). To optimize lead times, provide complete specifications and CAD models upfront, consider design modifications that simplify the forging process, approve standard material grades when possible, plan realistic production volumes, and establish a long-term partnership with your forging supplier. Working with a vertically integrated manufacturer who handles multiple production steps in-house can significantly reduce lead times by eliminating transfers between facilities. Implementing blanket purchase orders or stocking agreements for recurring orders can ensure material availability and priority scheduling, substantially reducing delivery times for subsequent orders.

Q: What quality standards should a reputable stainless steel forgings manufacturer meet?

A: A reputable stainless steel forgings manufacturer should meet and maintain several key quality standards. ISO 9001 certification is a fundamental requirement, demonstrating a solid quality management system. Industry-specific certifications are also important—aerospace forgings typically require AS9100D compliance, while medical components may need ISO 13485. Manufacturers should comply with ASTM, ASME, and SAE specifications for forging processes and material properties for critical applications. The ability to provide comprehensive material certification, traceability documentation, and dimensional inspection reports is essential. Advanced testing capabilities should include hardness testing, chemical composition analysis, mechanical property verification, ultrasonic testing, magnetic particle inspection, and dye penetrant testing. The manufacturer should have documented procedures for process control, non-conformance management, and continuous improvement. Third-party audits and customer approvals from significant OEMs in relevant industries further validate a manufacturer’s quality system. Carbon steel and other alloy forgings may have different requirements, but the quality systems should be equally robust.

Q: How does material selection impact the performance of stainless steel forgings?

A: Material selection is perhaps the most critical factor determining stainless steel forgings’ performance and service life. Different stainless steel grades offer varying corrosion resistance, strength, heat resistance, and fabricability levels. Austenitic grades (304 and 316) provide excellent corrosion resistance and formability but moderate strength. Martensitic grades (such as 410 and 420) deliver higher strength and hardness but less corrosion resistance. Precipitation-hardening grades (like 17-4PH) balance good corrosion resistance with high strength achieved through heat treatment. Duplex stainless steels combine attributes of austenitic and ferritic structures, offering superior strength and stress corrosion cracking resistance. The operating environment directly impacts material selection—considerations include exposure to chlorides, acids, high temperatures, cyclic loading, and potential for galvanic corrosion. The protective oxide layer on stainless steel surfaces provides corrosion resistance, but this can be compromised in specific environments. Working with a manufacturer experienced in forged steel applications can help ensure the optimal grade selection for your specific performance requirements and cost considerations.