Get in touch with us

Leave a message

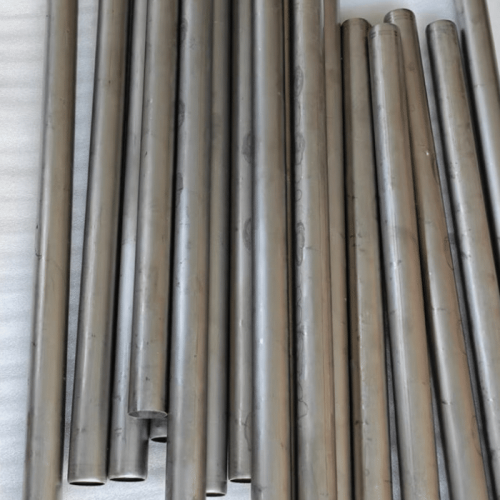

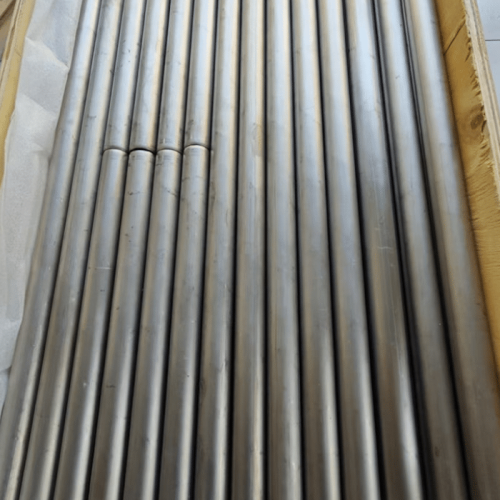

The GH5188 Cobalt Alloy Tube, a premium cobalt-based alloy, is engineered for exceptional performance in extreme environments. Known for its high-temperature strength and corrosion resistance, this cobalt alloy pipe is ideal for demanding applications in aerospace, power generation, and chemical processing. Its robust cobalt alloy composition ensures durability and reliability, making it a preferred choice for industries requiring resilient materials.

For detailed pricing on the GH5188 Cobalt Alloy Tube, please contact our sales team to request a customized quote. Pricing terms are tailored based on order volume, specifications, and delivery requirements. Reach out today to discuss your needs for this high-performance cobalt alloy tube.

The GH5188 Cobalt Alloy Tube is available in a range of dimensions and finishes to meet diverse industrial needs. Below are the standard specifications:

The GH5188 Cobalt Alloy Tube offers distinct advantages, making it a standout in the realm of cobalt-based alloys:

The GH5188 Cobalt Alloy Tube is widely used across various industries due to its exceptional cobalt alloy properties. Common applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 20.0 - 24.0 |

| Nickel (Ni) | 20.0 - 24.0 |

| Tungsten (W) | 13.0 - 16.0 |

| Iron (Fe) | ≤ 3.0 |

| Carbon (C) | 0.05 - 0.15 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 860 MPa |

| Yield Strength (0.2% Offset) | ≥ 415 MPa |

| Elongation | ≥ 30% |

| Hardness (Brinell) | 200 - 240 HB |

The GH5188 Cobalt Alloy Tube demonstrates excellent resistance to chemical degradation, making it suitable for corrosive environments:

While the GH5188 Cobalt Alloy Tube is highly versatile, certain limitations should be noted:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Rural) | < 0.01 |

| Seawater | 0.02 - 0.05 |

| 10% Sulfuric Acid (25°C) | 0.10 - 0.20 |

The GH5188 Cobalt Alloy Tube supports various welding and fabrication methods, ensuring flexibility in manufacturing:

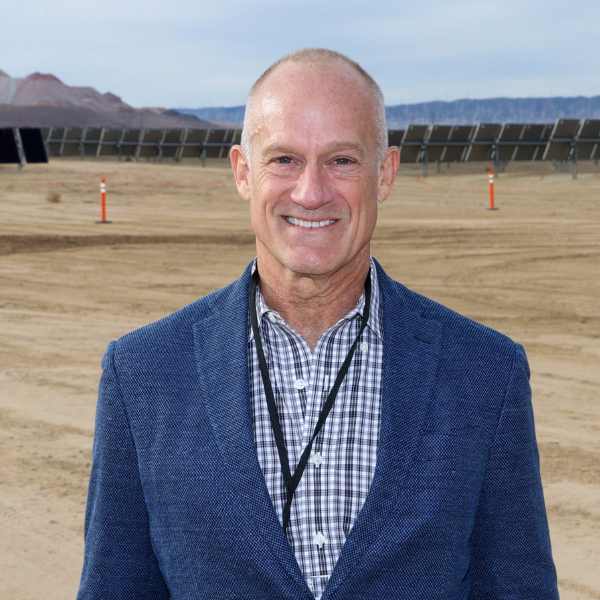

The GH5188 Cobalt Alloy Tube exceeded our expectations in turbine applications. Its heat resistance is outstanding, and the supplier’s support was exceptional.

John M.

Aerospace Engineer

We’ve used these Cobalt Alloy Tubes in corrosive environments with zero failures. Highly reliable and worth the investment.

Lisa K.

Chemical Plant Manager

The durability and ease of fabrication make this Cobalt Alloy Pipe a top choice for our heat exchangers.

Mark T.

Power Generation Specialist

A: While both are cobalt-based alloys, the GH5188 Cobalt Alloy Tube offers superior high-temperature strength, whereas Stellite is often preferred for wear-resistant coatings.

A: Aerospace, power generation, and chemical processing industries benefit significantly due to its cobalt alloy properties.

A: Yes, it supports TIG and MIG welding with proper preparation, as outlined in the welding section.

A: Yes, it adheres to RoHS and REACH standards, ensuring minimal environmental impact.

A: Pricing depends on dimensions, order volume, and market fluctuations in raw material costs.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.