Get in touch with us

Leave a message

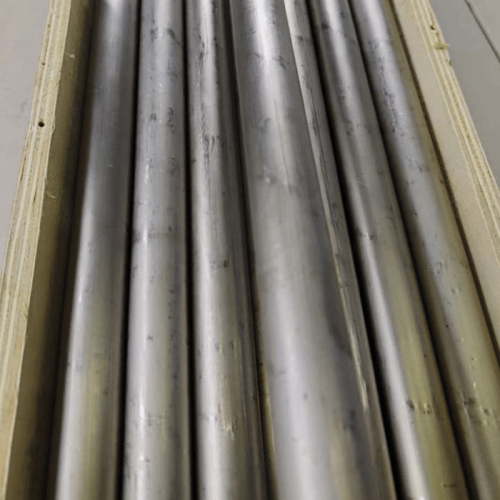

The 1J22 Cobalt Alloy Pipe, a premium cobalt-based alloy, is engineered for exceptional performance in high-temperature and corrosive environments. Renowned for its magnetic properties and durability, this cobalt alloy steel is a top choice for industries requiring precision and reliability. Its unique cobalt alloy composition ensures superior strength and resistance, making it ideal for specialized applications.

For detailed pricing and customized quotes on the 1J22 Cobalt Alloy Pipe, please contact our sales team. We offer competitive pricing terms tailored to your project requirements, ensuring cost-effectiveness for bulk and specialized orders.

The 1J22 Cobalt Alloy Pipe is widely used across various industries due to its robust cobalt alloy properties. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | 50.0 - 52.0 |

| Iron (Fe) | Balance |

| Nickel (Ni) | 0.5 - 1.0 |

| Vanadium (V) | 0.1 - 0.5 |

| Carbon (C) | ≤ 0.04 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 980 MPa |

| Yield Strength | ≥ 750 MPa |

| Elongation | ≥ 10% |

| Hardness (HB) | 200 - 250 |

The 1J22 Cobalt Alloy Pipe exhibits excellent resistance to acids such as sulfuric and hydrochloric acid, as well as alkalis like sodium hydroxide. However, it is not recommended for use in environments with high concentrations of oxidizing agents, which may affect its longevity.

While the 1J22 Cobalt Alloy Pipe excels in many conditions, certain limitations should be noted:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | ≤ 0.01 |

| Seawater | 0.02 - 0.05 |

| Dilute Sulfuric Acid (10%) | 0.03 - 0.07 |

The 1J22 Cobalt Alloy Pipe supports multiple welding methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. For optimal results:

Forming techniques such as cold drawing and hot rolling are recommended, ensuring precision in shaping without compromising the nickel cobalt alloy structure.

The 1J22 Cobalt Alloy Pipe from this China manufacturer exceeded our expectations. Its magnetic properties are perfect for our turbine components, and the custom sizing was spot-on.

John M.

Aerospace Engineer

We’ve been sourcing cobalt base alloy pipes for our chemical plant, and this product’s corrosion resistance is outstanding. The sales team was responsive and provided excellent support.

Lisa K.

Procurement Manager

The quality of the 1J22 Cobalt Alloy Pipe is unmatched. It’s been a game-changer for our magnetic shielding applications, and the delivery was prompt.

Ahmed R.

Electronics Specialist

A: While both are cobalt-based alloys, the 1J22 Cobalt Alloy Pipe is optimized for magnetic applications, whereas Stellite is typically used for wear-resistant coatings. The 1J22 offers superior magnetic permeability.

A: Aerospace, electronics, medical, and energy sectors frequently utilize the 1J22 Cobalt Alloy Pipe for its strength and corrosion resistance.

A: Yes, but prolonged exposure above 800°C may cause oxidation, requiring protective coatings.

A: Absolutely, we offer tailored dimensions and surface treatments to meet specific project needs.

A: Contact our sales team for a personalized quote based on your order specifications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.