Get in touch with us

Leave a message

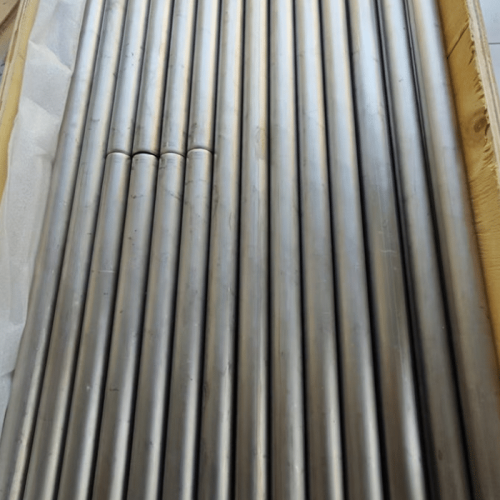

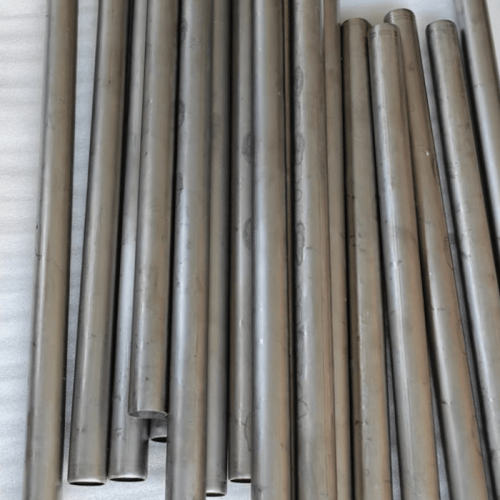

The 3J21 Cobalt Alloy Tube, a high-performance cobalt-based alloy, is designed for superior strength, wear resistance, and elasticity in demanding environments. Its cobalt alloy composition makes it a preferred choice for industries requiring precision and durability, offering excellent performance in high-stress applications.

For competitive pricing and tailored quotes on the 3J21 Cobalt Alloy Tube, please reach out to our sales team. We provide flexible pricing terms to suit your project specifications, ensuring value for both standard and custom orders.

The 3J21 Cobalt Alloy Tube is valued for its cobalt alloy properties across multiple industries. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | 39.0 - 41.0 |

| Nickel (Ni) | 15.0 - 17.0 |

| Chromium (Cr) | 19.0 - 21.0 |

| Molybdenum (Mo) | 1.5 - 2.5 |

| Iron (Fe) | Balance |

| Carbon (C) | ≤ 0.12 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 1300 MPa |

| Yield Strength | ≥ 1000 MPa |

| Elongation | ≥ 8% |

| Hardness (HV) | 350 - 400 |

The 3J21 Cobalt Alloy Tube offers robust resistance to acids like nitric and phosphoric acid, as well as alkalis such as potassium hydroxide. It is not suited for environments with high concentrations of chloride ions, which may induce pitting corrosion.

While the 3J21 Cobalt Alloy Tube is highly versatile, certain limitations should be considered:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Industrial) | ≤ 0.015 |

| Seawater | 0.05 - 0.10 |

| Dilute Nitric Acid (10%) | 0.02 - 0.06 |

The 3J21 Cobalt Alloy Tube supports welding methods such as TIG and plasma arc welding. For best results:

Fabrication techniques like cold forming and precision machining are recommended to maintain the nickel cobalt alloy’s structural integrity.

The 3J21 Cobalt Alloy Tube has been a reliable choice for our aircraft springs. Its elasticity and durability are exceptional, and the manufacturer’s support was outstanding.

Maria S.

Aerospace Technician

We use this cobalt base alloy for surgical tools, and its corrosion resistance is top-notch. The custom sizing options made integration seamless.

David L.

Medical Device Engineer

This tube’s wear resistance has improved our machinery’s lifespan significantly. The China manufacturer delivered on time and met all our specifications.

Chen W.

Industrial Manager

A: 1. How does the 3J21 Cobalt Alloy Tube differ from Stellite?

The 3J21 is optimized for elasticity and wear resistance in dynamic applications, while Stellite excels in hard-facing and wear-resistant coatings.

A: 2. What are the primary cobalt alloy uses for this tube?

It’s widely used in aerospace, medical, automotive, and industrial sectors for springs, implants, and high-stress components.

A: We offer tailored dimensions, wall thicknesses, and surface treatments to meet project needs.

A: Contact our sales team for a personalized quote based on your requirements.

A: TIG and plasma arc welding with compatible fillers and post-weld heat treatment ensure optimal performance.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.