Making steel hand drums is not solely about tradition; craft and knowledge play an essential role. It is mainly about rethinking instruments, which is, if not musical, the most fundamental: the material selection. Drummers prefer DCO4 carbon steel over any other kind, and there is a particular reason for this. Why,? Why does DCO4 steel, of all grades, contain ‘extra value’ within itself? This guide examines why DCO4 steel is still so different from the rest of the pieces and where to do their fairness enhancement, heavy weight enhancement, and finishing of the hand drums. There are drums to be played, a seasoned hand to hit the percussion, or even a steel tongue drum, and you insist on understanding why it is made of DCO4 steel. Well, worry no more; considering that question was rhetorical, discover why DCO4 steel is enhanced further in all its innovativeness and unlimited imagination. Seek and you will find vibrations, artistry, and history calling for such physics.

Understanding DCO4 Steel

In essence, high-grade cold-rolled steel such as DCO4 falls into the category of steel grades that can be broadly described as strong, tough, and highly formable. The homogeneity and flawless surface of the DCO4 steel make it very suitable for making body shells of such instruments as hand drums. To provide sustainability instruments with their shape & design, alloy features, and workability. All these characteristics make DCO4 steel widely used by craftsmen and instrument users.

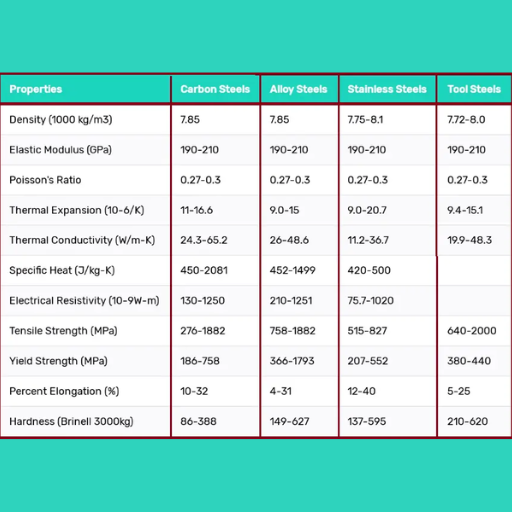

Properties of DCO4 Steel

DCO4 grades are designed with high quality, with stiffness, ease of forming, and the best finish possible. This steel type is the largest market for most uses of long life and accurate forming, such as making cans, household equipment, and many other engineering parts. The specifics of DCO4 steel and its properties are given below:

- Strength in Terms of Mechanics

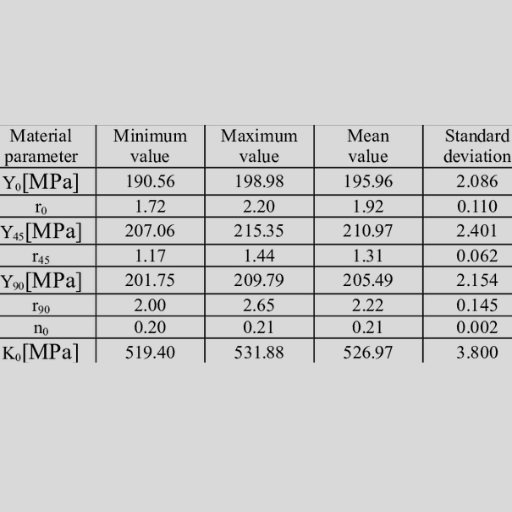

The tensile strength of DCO4 steel, which is in the range of 270–350 MPa, allows this material to be stretched and worked with great stress without bending out of shape. The yield strength of 240 MPa or so of this steel is quite adequate for extended periods of use, which is particularly true of parts subject to constant mechanical friction.

- Polished Surface

It is subjected to stringent cold rolling processes that give the steel a very fine and glossy surface. This results in the ease of performing end-of-line processes, such as coating, painting, or any other processes, when needed, or the ability to resist surface scuffs and other mechanisms-induced damage that may be caused.

- Molding

Thanks to a higher degree of plasticity, DCO4 steel is suitable for simple shapes and parametric designs with complex detailing that does not sacrifice strength. It offers an elongation rate of 30 percent, which is applicable even for extended forms, precluding the use of precision instruments.

- The Composition

With carbon (≤ 0.08%), manganese (≤ 0.45%), phosphorus, and sulfur in tolerated proportions (≤ 0.035%), this is the range of the chemical composition of DCO4 steel, which adds greatly to its professed or theorized mechanical and chemical properties. These levels point to a sweet spot between high strength and machinability levels.

- Resistance to Corrosion

Though DCO4 steel is not stainless in construction, it is common to see coatings such as zinc or specialized finishes on the material to increase its corrosion resistance, especially in wet or hostile environments.

- The Thickness and Dimensions

This product offers standard gauges ranging from 0.3 mm to 3.0 mm to suit different types of industrial applications. Its dimensional stability also allows for precision applications, making it ideal for manufacturing precision-engineered products.

- Application

- In the Automotive sector, it is used for inner panels and other body parts.

- For Appliances, it is used mainly to manufacture robust and good-looking shells and frames.

- In musical instruments, it is recommended for producing sound results with longevity.

- For general engineering, it is helpful for parts that should be both robust and precise.

- Environmental Benefits

DCO4 steel can be recycled, thus reducing the impact on Mother Nature. Components with such long service lives allow rational material consumption and are thus suitable for companies that promote an image of eco-responsibility.

Key Data Metrics

| Property | Standard Value |

|---|---|

| Tensile Strength | 270–350 MPa |

| Yield Strength | ~240 MPa |

| Elongation (% at break) | Up to 30% |

| Carbon Content | ≤ 0.08% |

| Manganese Content | ≤ 0.45% |

| Thickness Range | 0.3–3.0 mm |

| Surface Finish | Uniform and smooth |

With its consistent quality and versatile properties, DCO4 steel remains a popular choice in industries where precision and performance are essential. Its adaptability across applications highlights its value as a high-grade material for modern manufacturing challenges.

DCO4 vs. DC03: Key Differences

| Key Point | Dyson DC04 | Dyson DC03 |

|---|---|---|

| Design | Bagless upright vacuum | Bagless upright vacuum |

| Suction Power | Powerful suction for carpets and floors | Standard suction for general cleaning |

| Filter | Washable filter | Washable filter |

| Hose | Extendable hose | Standard hose |

| Tools | Crevice and stair tools included | Basic tools included |

| Warranty | 12-month warranty (refurbished units) | No longer supported by Dyson |

| Maintenance | Easy to empty | Avoid overfilling for optimal suction |

| Availability | Refurbished units available | Discontinued, no parts available |

Applications of DCO4 Steel in Industries

It is apparent why different manufacturing sectors have benefited from this low-carbon steel, which tends to have better formability, toughness, and accuracy than other grades. The following five application scenarios illustrate the multifunctionality and usefulness of dco4 steel:

- Automobiles

- DCO4 steel is used for various purposes. The body of a car is its end component; how strong and how well it fits is very important.

- Specific Areas: Outer automotive skins, Sills, and Rear van carriage bodywork.

- Gains: Ideal shine for finish coatings without compromising on the ‘Looks’ of a car, for instance.

- White Goods Manufacturing

- Where It Fits: DCO4 steel layers are adopted in white goods with covert and non-oxidizing appearances.

- Examples: Washing Machines, Refrigerator doors, etc.

- Advantages: Enhances the aesthetic and functional longevity with minimum care requirements.

- Electro-Industry

- Application: It helps make housing and casings for the equipment.

- Examples: Casing of CPU, Mobile Battery Pack and Control Box.

- Advantages: Excellent Workability and Formability for Intricate Details in Equipment Design.

- Steel – Infrastructure

- Application: Light-gauge steel DCO4 is used in construction for living and commercial purposes.

- Examples: Sheet Metal for Roofing, Wall Sheeting, and Cladding.

- Advantages: It offers a high strength and low weight combination, thus minimizing construction time and cost.

- Packaging Sector

- Application: DCO4 is perfect for robust, adequate food and product packaging solutions.

- Examples: Cans, Containers, and Covers Made from Steel/Aluminum, Etc.

- Features: Very Good Resistance to Rusting and Very Smooth, I.e., Clean Surface Finishing for Delicate Media.

The wide range of applications within different industries proves the versatility and high-quality performance of DCO4 steel. It is an indispensable component of the modern manufacturing process.

Hand Drums and Handpans

Percussion instruments, such as hand drums and handpans, are played using the hands instead of drumsticks. The essential deep bass sounds of hand drums such as djembe and conga are often a staple of traditional musical performances or rhythm classes. However, the steelpan or handpan is a relatively new invention owing to its unique design and mellow sound. When made from higher grades of dco4 steel and are steel material, unfinished, the steelpan is referred to as a handpan. These tools are exciting since they combine different sounds, giving rise to any sound from aggressive to calm and focused. Therefore, they enable the use of rhythm and instruments in many genres of music and even in therapeutic music.

The Art of Making Steel Hand Drums

It takes a sophisticated yet simple technique to manufacture steel hand drums or handpans. The primary material used is high-grade DCO4 steel, which is reinforced into a dome or some other oval shape. Moreover, these processes begin with the easiest and most available steel one can get, but the steel should have some characteristics like a thickness that can be bent and tuned. Several processes, such as hammering, rolling, and forming, are employed to attain the desired curved surface of the drum that contains the tones needed for melody.

At the very beginning of the construction, the curve should be forged before using the welder’s hammer to adjust the tone field fixially. Otherwise, the drum will not be able to produce a melody consisting of sound waves coming in a volumetrically harmonic and serene way. Every handpan may contain 7 to 12 tone fields, depending on the scale and tuning that has to be achieved, and tuning these tone fields is usually a complex process. According to studies, the time taken to produce a single unfabricated steel drum can be between 40 and 100 hours for an experienced craftsman. Weaknesses sometimes may include a fixed structure, a note-by-note way of tuning the instruments, and using handhammers together with laser machines, if one intends to tune the instrument in such a way.

Conclusion: A worldwide supply of steel hand drums has grown over the past years, as people already understand the exceptional sound of this tool and its application in both performance and neomaietical domains. Analysis of the industry indicates that the handpan and steel drum industry is expected to register a compound annual growth rate (CAGR) of 6.7% between 2023 and 2030. It makes many believe that handpans and similar instruments, which are crucial in these practices, are gaining popularity,

Additionally, present-day manufacturers of handpans consider environmental responsibility throughout some of their production steps, such as using recycled materials and avoiding wastage. This provides an added incentive for green-conscious consumer categories to purchase these products. Whether a seasoned musician, therapist, or a mere hobbyist fascinated by playing the hand steel drum, it is the handiwork that goes further in every sound that draws one to every instrument.

Benefits of Using Carbon Steel in Handpans

| Key Point | Benefit Description |

|---|---|

| Sound Quality | Produces bright and lively tones |

| Ease of Shaping | Relatively easy to work with |

| Cost Efficiency | Low-cost and widely available material |

| Dynamic Range | Offers a wide range of sound dynamics |

| Sustain | Provides controlled and stable sustain |

| Corrosion Resistance | Can be treated to resist rust |

| Versatility | Suitable for various playing styles |

| Maintenance | Requires regular cleaning to prevent rust |

Comparing Different Types of Hand Drums

| Drum Type | Key Features | Cultural Origin |

|---|---|---|

| Djembe | Goblet-shaped, wide tonal range | West Africa |

| Tabla | Paired drums, intricate rhythms | India |

| Cajón | Box-shaped, bass and snare sounds | Peru |

| Darbuka | Goblet-shaped, crisp tones | Middle East |

| Bodhrán | Frame drum, played with a stick | Ireland |

| Congas | Tall, narrow, warm tones | Afro-Cuban |

| Bongos | Small, lively, bright tones | Afro-Cuban |

| Udu | Clay pot, resonant bass | Nigeria |

| Steelpan | Melodic steel drum, harmonic tones | Caribbean |

| Handpan | Steel, melodic and meditative tones | Modern (Swiss origin) |

Design and Analysis Tools for DCO4 Steel

Different tools and techniques can be used when designing and in the analysis of grades DCO4 steel more conveniently while achieving optimum accuracies and minimizing errors, such as:

- 3D FE analysis (use of F.E.M.)

The application of this FE Analysis helps in modeling the mechanical performance during different conditions of stress, deformation, and strain. This provides a comprehensive understanding of how a part will perform and how durable it is.

- Materials-Based Properties

View authentic materials bases such as Mat Web and mechanical properties of the DCO4 steel, such as strength against heat axes and structure.

- Designing Computer Programs

IN CAD, states axes provide the capability to build models and design drawings. These systems support analysis of the manufacturability to be hand in glove, even without thesis capabilities.

- Simillations Software

Several simulation programs are present for metalworking processes, with capabilities that can help determine flow temperature and defects of a product, among other things.

- Corrosion Engineering Devices

Metallurgical materials are subjected to corrosion in water easily or not; thus, using corrosion programs helps determine where specific materials need to be improved; otherwise, the case is what is anticipated.

This Indian design or analysis tool helps in quick design and building, and optimizes the developed design for a particular purpose. It avoids certain risks because of the operational requirements. Furthermore, without these processes, designing some working components out of DCO4 steel may be pretty impossible.

Utilizing GUI Tools for Steel Specifications

The introduction of Graphical User Interface (GUI) tools has transformed how engineers and manufacturers manage steel grade specifications. With the help of these utilities, users have an easy way of visualizing, analyzing, and comparing the requirements and properties of all the steel grades available. A good case in point is the DCO4 steel. Available systems for GUIs that do not use these types of graphical interfaces enable designers to pick the right steel the first time every time by providing all the engineering, production, and marketing information along with the project specifications for the particular steel on one screen.

Also, progressive graphical interfaces allow the user to mention, for instance, the required yield strength, ultimate tensile strength, and percent elongation, which are provided automatically; sets of diagrams and reports explicitly developed for the material are presented. Take, for example, DCO4 steel, a cold-formed grade with superior formability. Such a grade can be subjected to requirements of the thickness and/or surface finish needed, as suitable for the automotive structures packaging industry. Moreover, most of these tools are also compatible with standards and material databases, allowing the user to get the latest steel grades, such as EN 10130 or ASTM grades dco4 steel and other requirements.

Another improvement is including artificial intelligence and machine learning in the processes. Such systems analyze past experiences and extrapolate performance for the usefulness of the decision maker. Some applications, such as Matmatch and JmatPro, enable users to simulate the behavior of DCO4 steel in all the operational conditions, including changes in temperature and stresses. Based on recent findings, Zelda users and other professionals depend on Autodesk Fusion 360 or similar tools to display complex assemblies with their respective materials.

Next, CAD programs in most GUI tools may be compatible with the design, promoting interaction. Facilities shall simulate DCO4 steel’s interaction with other materials, identify danger zones, and make structures lighter and more durable. Visualization tools like heat maps and stress ranges help make better designs and manufacturing due to the physical process of putting in the work.

State-of-the-art GUI tools integrated into steel–based product engineering assist manufacturers in enhancing the quality and performance of their products without wasting significant amounts of time or making mistakes.

Heat Transfer Analysis in DCO4 Steel

| Key Parameter | Description |

|---|---|

| Thermal Conductivity | 45-55 W/(m·°C), varies with temperature |

| Heat Capacity | 460 J/(kg·°C) at 50-100°C |

| Thermal Expansion | 12 x 10⁻⁶ (30-100°C range) |

| Density | 7.86 g/cm³ |

| Modulus of Elasticity | 210,000 MPa at 20°C |

| Maximum Application Temp | ~200°C for mechanical stability |

| Corrosion Resistance | Requires coating for protection |

| Weldability | Excellent, suitable for laser cutting |

Designing Heavy-Duty Hand Drums with DCO4

While considering the grades of DCO4 steel GUI in thick-walled cylinder design, the strength of the material and structural strength properties, as well as fabrication methods, must be considered to obtain the best results. This document provides an in-depth analysis of the process, including the main benefits of using DCO4 structural steel.

- Material Strength and Durability

DCO4 steel’s tensile strength ranges from 300 to 400 MPa. Its efficient toughness makes it suitable for overhead loads and cyclic stresses within harsh environments.

- Corrosion Resistance

Due to its improved chemical composition, DCO4 is resistant to corrosion and environmental decay, which lessens maintenance requirements and increases the product’s service life even in adverse environments.

- Heat Resistance

Dco4 grade steel is particularly outstanding because of its enhanced capability to retain its form in a hot environment, raising temperatures. This is possible due to its Heat Transfer Coefficient, which allows safe performance in ambient heat.

- Precision Manufacturing Capabilities

Due to DCO4’s high machinability, most manufacturers work within close tolerances, allowing for precise drum formations and smooth finishes, which are critical for proper functioning and accompaniment of other parts.

- Weight-to-Strength Ratio

Hand drums crafted from DCO4 steel boast a remarkable balance between weight and strength, „making them perfect for lightness in transport and use without compromising on strength.

Working on these aspects helps manufacturers fully exploit the use of DCO4-contained steel in making and designing efficient heavy drums that satisfy their users.

Stainless Steel vs. Carbon Steel Hand Drums

| Key Parameter | Stainless Steel Hand Drums | Carbon Steel Hand Drums |

|---|---|---|

| Sound Sustain | Longer sustain, up to 6 seconds | Shorter sustain, more controlled |

| Timbre | Bright, open, and rich tones | Warm, ceramic, and mellow tones |

| Corrosion Resistance | Highly resistant to rust | Requires treatment to resist rust |

| Durability | Resistant to surface damage | Prone to rust if coating is damaged |

| Playing Style | Ideal for meditative, slow playing | Suitable for rhythmic, ensemble playing |

| Maintenance | Low maintenance, less frequent oiling | Requires regular oiling and care |

| Material Stability | Newer, less time-tested | Time-tested and stable |

| Cost | Generally more expensive | Typically more affordable |

Durability and Performance Comparison

Stainless steel and carbon steel drums have to be analysed carefully in terms of their longevity, effectiveness, and appropriate application. Each has some benefits and limitations that will affect their use in the same business.

Stainless Steel Drums

- Anti-Corrosion Properties

Drums made of stainless steel are highly resistant to rust and corrosion. And because of that, they are perfect for storing and transporting different liquids, including chemicals, pharmaceuticals, and food products. The Chromium content in them creates an oxide layer on the surface of the stainless steel, which allows these drums to be used in such environments for a long time. Previous research indicates that stainless steel can withstand over 20 years in corrosion environments, requiring little maintenance.

- Heat and Strength Advantages

They are capable of surviving harsh conditions such as hot and cold extremes. Even so, most Steel grades, such as dco4 steel gui 2B, which includes 304 and 316 grades of stainless steel, can take up to 1,500 degrees Fahrenheit and even more if needed.

- Green and Cost Savings

The initial purchase price of stainless drums may be higher when they are first bought; however, due to their resistance to changing often, they become economical in the long run. Besides, stainless drums, which are manufactured of steel, can be recycled to contribute to sustainable development, hence helping conserve the environment.

Carbon Steel Drums

- Affordability

In contrast, carbon steel drums are cheaper from the outset than stainless steel ones; hence, they can be bought for short-term use or within constrained costs. Such containers are most preferred in cases where there is improved mobility in that vessels are expected to be changed at intervals.

- Ratio of Strength to Costs

In terms of thickness and metal concentration, the higher the tensile strength of the container, the more stationary it will be. Hence, stainless steel is cheaper and stronger because better-quality fuel lends itself to carrying non-corrosive solids even if it is not as zone-resistant as stainless steel.

- Protection of the Surface

To prolong the service life of carbon steel drums, they are usually coated or applied with various protections, e.g., epoxy coats or phenolic resins. This facilitates the preservation of products used in oils, solvents, or powder form, most importantly due to the depth of this kind of storage implemented.

Data Comparison

| Feature | Stainless Steel | Carbon Steel |

|---|---|---|

| Corrosion Resistance | Excellent (Oxide Layer) | Moderate (With Coatings) |

| Temperature Resistance | Up to 1,500°F | Up to 1,000°F |

| Weight | Heavier | Lighter |

| Initial Cost | Higher | Lower |

| Maintenance | Minimal | Coating Reapplication Needed |

| Recyclability | 100% | Limited |

Choosing the Right Material

Whether to use stainless steel or carbon steel drums depends mainly on the purpose of the working environment. Due to the excellent durability and performance seen in such structures, stainless steel is usually used for expensive things or corrosive chemicals to be stored for extended periods; otherwise, carbon steel is used in cost-saving materials where the contents are non-corrosive or have a limited usage time.

Thus, the ability to determine the consequences and to use materials appropriately in conjunction with the given situation would help the manufacturers perform well and maximize the process itself.

Cost Considerations in Material Choice

In material selection, cost effectiveness is becoming increasingly important, given the prevailing economic forces, including market demands and the use of search engine materials grades, dco4 steel gui, requiring compromise on initial costs, enhanced performance, and extended service life, preventive maintenance notwithstanding.

Innovative Designs Using Stainless Steel

Modifying products that use trail-blazing fabrication principles is among other innovative ways that I think of when making changes to grades of DCO4 steel because it is durable, resistant to rust, and attractive. It is out of these aspects, along with contemporary ways of fabrication, that the design is possible for me, functional, and at the same time appealing. Be it in construction works, manufacturing equipment, or consumer goods. Stainless steel offers that flexibility in building lasting and efficient performance in whichever area a solution is needed.

In almost all cases, different grades of dco4 steel have specific colors; some are predominantly gray or darker, while others are lighter shades. Therefore, if somebody wants to change the colors, he has to start thinking of newer grades of steel that are different from the ones currently in use. The GUI will allow you to select the desired tarnish color by using parameters preloaded in the system.

Future Trends in Hand Drums

The change in hand drum construction is partly attributed to the shift in musical taste, the availability of materials and the demand for them. Most people prefer lighter, hence more portable instruments, and they are available in heavy-duty materials with protection from wear and tear. On the same note, electronic capabilities in hand drums—referred to as hybrid instruments—are increasingly being embraced by different categories of musicians because they give the player the freedom to produce various sounds. The rising phenomenon of customization motivates players to decorate their tools, clean or even change the head to the grades dco4 steel gui their drums. Sustainability of the process is also considered, whereas the producers are looking to manufacture more ‘green’ tools because there is an external push to do so. All these new directions point out a trend towards the innovation and distinctive personalization of hand drums.

Emerging Technologies in Handpan Production

Technological improvements have taken handpan structures to another level. Even though the manufacturing possibilities have expanded, the accuracy of sound and more customization of the final instrument are being realized. In this regard, it is worth mentioning a vital development – computer numerical control (CNC) machines, which are used to shape steel and work on tuning it. Automating the tasks enables standard tuning throughout the output level, reducing people’s mistakes; hence, the time required for production is reduced.

Another development is that high-strength grades of dco4 steel, gui stainless steel, or nitrided steel are adopted to construct hand pans to last longer without corrosion. This implies that they remain within the parameters of their sound and look even when exposed to moisture. Research findings show that most players have warmly embraced stainless steel handpans because they are lighter and produce brighter sounds than the other conventional materials.

Even more advanced technology, such as 3D modelling, is used to create new handbag designs. Experimenting with various combinations of scales, diameters, and resonance properties would normally require expensive trial-and-error testing; however, fitting different configurations is carried out only on computers, therefore substantially saving R&D expenses.

Moreover, new tools powered by artificial intelligence are helping to enhance the tuning process. These tools detect every wave and how sound characteristics change, which helps luthiers achieve pitch and resonance in less time than usual tuning techniques.

Green measures like using steel from recycling bins or using less power-consuming methods for manufacturing are affecting the present industrial scene. Many producers are addressing the trend towards going green by reducing the unregulated emissions from production without significantly compromising the quality of the instruments produced.

To cap it all, there are other emerging technology-based teaching aids in the form of AR apps targeted at teaching novices how to make handpans. Such aides feature pretty accurately how to save it up, tune, and put together, so even those willing to do some crafting do not face such a heavy barrier of entry, and the market does not suffer from the lack of craftsmen who know how to craft them.

Such developments are paving the way for the next generation of handpan makers, who can integrate the traditional form of making the instrument with modern techniques that provide balance for player collectors across the globe.

Environmental Impact of Steel Production

Steel production contributes greatly to degrading the environment, given the magnitude of energy required to produce it and source its raw materials. The details of its environmental impacts are highlighted below and supported by statistics and analyses.

- The Scourge of Carbon Emissions

Steel production industries are the world’s top polluters by carbon emissions, which is approximately 7% of the total greenhouse gases globally released due to human activities. To be precise, every ton of steel produced releases approximately 1.8 tons of carbon dioxide owing to reliance on the traditional blast furnace method.

- The Consideration of Power Usage

The steel manufacturing process consumes large energy resources, which are typically generated using fossil fuels. The World Steel Association indicates that, depending on the steel manufacturing process and plant design, it requires about 20-25 gigajoules of energy to produce 1 ton of steel.

- Consumption of Iron and Coal

Consumption of raw materials for steel manufacturing, such as iron ores and coking coals, is another concern due to the overexploitation of the world’s natural resources. Consider the following materials: about 1.4 tons of iron ore and about 0.8 tons of coal are consumed in making 1 ton of crude steel.

- Use of Water and Disposal of Effluents

Steelmaking involves extensive water use, mainly for cooling and other auxiliary processes. For every 1 ton of steel reinforcement produced, approximately 120,000 liters of water are consumed. Steel plants’ discharges are not only significant in quantity but also contain impurities, mainly heavy metals.

- Solid Waste Management

Steel manufacturing entails the disposal of large quantities of solid wastes such as slags and dust. The average waste produced is 200 kg per ton of steel manufactured. Managing waste is a key challenge because although a considerable amount of slag is utilized in making infrastructure, most of the waste remains unused.

Addressing these sources of pollution is imperative to promoting a more sustainable steel industry based on advanced technologies, including electric arc furnaces, recycling, and energy conservation.

Grade DCO4 steel is one of the most common steel grades used to produce steel hulls. The GUI here provides a simple interface that will help the user work more effectively with the database.

The Future of GUI in Steel Design

Shortly, in my vision, the steel GUIs will only expand by improving interfaces and adding function mirrors regarding this oversimplification of the users’ experience. Next-generation tools with AI-based recommendations, instant analysis, and easy communication features will change the contemporary outlook on design projects. Additionally, accessibility and customizability are achieved to enable GUI users, regardless of their grade, whether experts or beginners, to facilitate improvement, error-free processes, and creativity.

References

- SteelPRO Group: This site offers an in-depth guide on DC04 steel, including its composition, properties, applications, and processing methods. It is a comprehensive resource for understanding the material’s characteristics and uses. Source

- Thyssenkrupp Materials Processing Europe: This page provides technical details about DC04 steel, including its mechanical properties, chemical composition, and suitability for high forming requirements. Thyssenkrupp is a well-known and reputable supplier of steel materials. Source

- Hebei Yehui Metal Materials Co., Ltd.: This article compares DC04 with CR4 cold-rolled steel, highlighting their properties, applications, and differences. It provides valuable insights into DC04’s advantages in specific industries. Source

Frequently Asked Questions (FAQ)

What is DC04 steel, and its applications in the automotive industry?

DC04 steel is a minor steel grade commonly used in manufacturing due to its excellent formability and weldability. It is particularly popular in the automotive industry for making components such as body panels and other structural elements. The mechanical properties of DC04 steel, including its hardness and strength, make it suitable for applications that require durability and resilience.

How does the thickness of 1.2mm affect the performance of DC04 steel?

The thickness of 1.2mm in DC04 steel plays a crucial role in its performance and applications. Thinner gauges, such as 1.2mm, allow for greater flexibility and ease of shaping, making it ideal for intricate designs in various manufacturing processes. However, the thickness also influences the steel’s strength and sound quality when used in products like handpan drums and other musical instruments.

Can DC04 steel be nitrided to enhance its properties?

Yes, nitriding DC04 steel can enhance its surface hardness and wear resistance. This heat treatment process involves introducing nitrogen into the steel’s surface, which can significantly improve its durability. Nitrided DC04 steel is often utilized in applications with increased surface hardness, making it suitable for components exposed to friction and wear.

Why is DC04 steel considered a high-quality material for manufacturing?

DC04 steel is considered high-quality due to its excellent mechanical properties and ability to meet industry standards. It exhibits various applications, from automotive components to household appliances. The combination of formability, weldability, and strength makes DC04 an ideal choice for manufacturers looking for reliable materials.

What role does DC04 steel play in the production of handpan drums?

DC04 steel is often used to produce hand pan drums, particularly for its rich sound quality. The steel’s mechanical properties allow for precise tuning, essential for achieving the desired musical notes. The 10mm thickness is often used to construct these instruments to ensure durability and acoustic performance.

What are the benefits of using minor steel grades like DC04?

Using minor steel grades like DC04 offers several benefits, including improved formability and ease of processing. These steels are often more affordable than higher-grade materials while providing adequate strength for various applications. They are widely used in the automotive sector and in the production of musical instruments such as handpan drums, where sound quality is paramount.

How does the hardness of DC04 steel compare to other steel grades?

DC04 steel’s hardness is typically lower than that of higher-grade steels, but it is sufficient for many applications, especially in automotive and consumer goods. Its hardness can be further enhanced through nitriding or ammoniation, making it versatile. When choosing steel grades, it is essential to consider the application’s specific requirements.

What materials are commonly used alongside DC04 steel in manufacturing?

In manufacturing, DC04 steel is often used alongside other materials such as aluminum and high-strength steels. Each material serves different purposes based on the desired properties, such as weight reduction or increased strength. Combining DC04 with other materials can optimize the overall performance of the final product, especially in automotive and appliance applications.