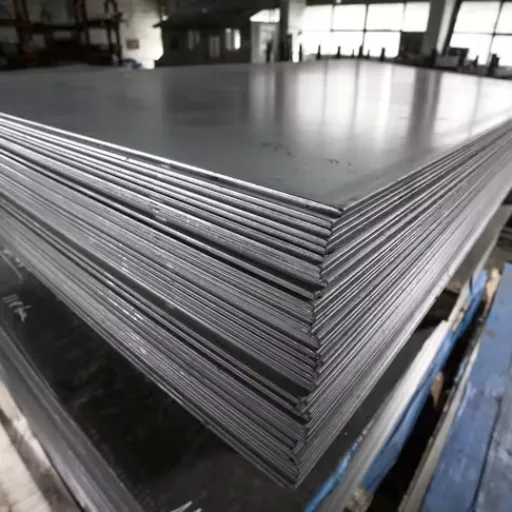

The selection of stainless steels for your project involves an understanding of the particular properties and applications of each stainless steel. Out of the many variants of stainless steel, steel 434 so to say, is preferred in many applications due to its high corrosion resistance and durability. So what makes 434 stainless steel special, and how can working with it assist you with your next project? This manuscript elaborates upon a few of the properties, benefits, and uses of 434 steels, which will give you the knowledge to enable you to make the best choices. Whether you are seasoned in the industry or simply starting out and want to explore some stainless steel options, this article will help you hone your skills.

Importance of Stainless Steel in Industries

Stainless steel has been important constituting material in almost all industries due to its unparalleled strength, corrosion resistance, and applicability. Industry statistics reported that the global stainless steel market size was valued at around 111.45 billion dollars in 2022 and will grow at a CAGR of 5.0% between 2023 and 2030. The steady growth indicates rising demand and relevance all over the world.

Key Industry Applications:

- Construction: Structural components, cladding, and roofing with 25+ years durability

- Medical & Pharmaceutical: Surgical instruments and hospital-grade equipment

- Food Processing: Hygienic surfaces and equipment

- Automotive: Components requiring high strength and corrosion resistance

Being resistant to rust and stains is one of the most remarkable properties of stainless steel. That is why it finds optimum applications in areas subject to moisture, chemicals, or extreme temperature. Industries like construction, automobile, and food processing highly value stainless steel for its staying power and hygienic qualities. Applications for stainless steel within construction include structural components, cladding, and roofing, which can endure severe weathering for 25 or more years with little maintenance.

Similarly, it is important for the medicinal and pharmaceutical industries, where sterile and easily cleanable surfaces are critical requirements. Stainless steel is preferable for manufacturing medical devices, surgical instruments, and hospital-grade equipment to ensure their safety and compliance with sanitation standards. On the other hand, in terms of sustainability, stainless steel enjoys almost the highest recycling rate, with more than 80% recycled worldwide, bringing it a step closer to the ever-growing trend for environmentally friendly manufacturing practices.

Composition of Steel

Steel is primarily an iron-carbon alloy, with other elements such as manganese, chromium, nickel, and molybdenum added in varying quantities depending on the properties desired. Carbon in steel ranges, in general, from 0.1% to 2.1% by weight; the higher the carbon, the stronger and harder the steel, but weldability and malleability decrease. Chromium is the most important element used in stainless steel: it is generally present at approximately 10.5% and above; it forms an impermeable, very thin oxide layer on the surface of the steel to prevent corrosion and provide durability.

Global Steel Production Facts:

- Global steel production exceeded 1.88 billion metric tons in 2022

- China accounts for 53% of total production

- Major producers: India, Japan, and the United States

- Growing demand for high-performance grades like HSLA and AHSS

Taxes report that global steel production went beyond 1.88 billion metric tons in 2022, with China accounting for 53% of the total production. India, Japan, and the United States are major producers after China. This growing demand for high-performance steel grades such as high-strength low-alloy (HSLA) steel and advanced high-strength steel (AHSS) reflects the growing need for lightweight yet durable materials in modern industries, particularly automotive and constructions. Also, on the sidelines, great attention is being given to sustainable steel production, spearheaded by innovations such as hydrogen-based steelmaking and recycled steel.

Applications, Uses, and Benefits of Grade 434 Stainless Steel

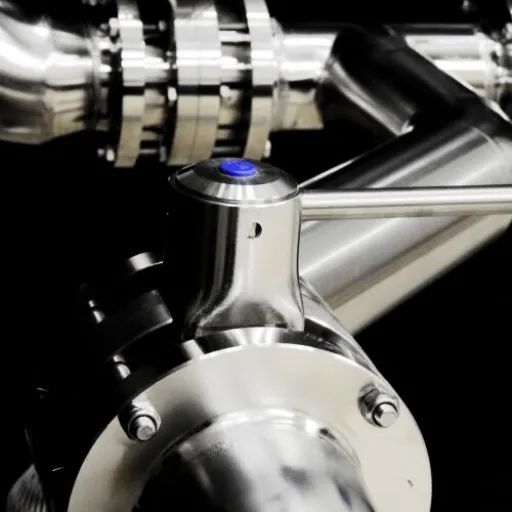

Grade 434 stainless steel is ideal for automotive trimming, chemical processing equipment installation, and marine application, courtesy of the very good corrosion resistance it enjoys, together with high tensile strength and reasonable formability.

Advantages in Specific Uses

Depending on specific applications, there are properties a Grade 434 stainless steel possesses-that make it useful-which would attract industries across different trades:

🚗

Automotive Uses

Used widely by manufacturers in exhausts, catalytic converters, and trim issues, then the excellent resistance to oxidation and heat by Grade 434 stainless steel will guarantee that its durability survives in environments that are elevated in temperature. Studies reveal that Grade 434 stainless steel can resist temperatures up to 870°C (1600°F) and, thus, give assurance as the most reliable for such applications.

🏗️

Construction and Architecture

Due to Grade 434’s resistance to atmospheric corrosion and its low maintenance need, it has been used for cladding panels and handrails for these reasons. Testing has shown that its smooth finish will go on with visual appeal even through decades of urban pollution, thereby lowering any cost that might be encountered through repairs or replacements.

⚓

Marine Applications

HD 434 resists chloride corrosion to a great extent, hence performing well in a saltwater environment. On the chloride pitting resistance studies, HD 434 appears to hold an eminent advantage over common stainless steel types, making it suitable for use in boat fittings, dock structures, and other marine equipment.

Innovation and New Trends for Usage

The Grade 434 stainless steel has gained new, innovative usage, placing increasing demand in different areas due to technical developments and changing needs of the market. One trend is its growing use in renewable energy systems, especially for the frames of solar panels and components of heat exchangers. It is an ideal material for sustainable energy solutions due to its ability to resist harsh environmental conditions and high temperatures. As per recent reports, the stainless steel market at a global level is forecasted to experience a compound annual growth rate of 5.5% between 2023 and 2030, with Grade 434 significantly fostering this growth on account of being cost-effective and durable.

Automotive Industry Benefits:

- Can reduce vehicle weight by up to 15%

- Improves fuel economy

- Reduces adverse environmental impact

- Excellent for exhaust systems and structural elements

Another important development entails the wider applications of Grade 434 stainless steel in advanced car designs. In order to reduce chassis emissions and in turn increase fuel efficiency, car manufacturers are integrating this alloy more into exhausts and structural elements. This is because of its unmatched corrosion-resistance and thermal characteristics, all coupled with the industry’s drive for lightweight and high-strength materials. As a matter of fact, studies show stainless steel use can reduce vehicle notoriety by as much as 15%, boosting fuel economy while simultaneously dragging down its adverse environmental impact.

Comparison with Other Stainless Steel Grades

Grade 434 stainless steel scores much higher in corrosion resistance among all grades under examination, especially from chlorides. While Grade 304 is favorable to many, its ability to better resist pitting and stress corrosion makes Grade 434 a choice to be made for applications subjected to conditions of harsh nature. Also, it does not possess ultimate tensile strength equal to that of Grade 316 but does prove well worth cost-wise, working ability of the area, and does require hardly any maintenance.

| Grade | Chloride Resistance | Cost Efficiency | Maintenance |

|---|---|---|---|

| Grade 434 | Excellent | High | Low |

| Grade 304 | Good | Medium | Medium |

| Grade 316 | Very Good | Lower | Medium |

Stainless Steel Classifications

Martensitic vs. Ferritic Stainless Steels

Stainless steels are classified into different families based on their microstructure, among which martensitic and ferritic stainless steels are those commonly used because of their specific properties and applications. Knowing the differences between the two is an important step toward choosing the right material for the job.

Martensitic Stainless Steels

- 12-18% chromium content

- Low carbon content

- Can be hardened by heat treatment

- Excellent strength and wear resistance

- Moderate corrosion resistance

Popular grades: 410 (strength & affordability), 420 (knives & medical instruments)

Ferritic Stainless Steels

- 10.5-30% chromium content

- Low or zero nickel

- Good ductility and toughness

- Resistant to stress corrosion cracking

- Cost-effective due to low nickel

Popular grades: 430 (architecture & kitchen), 434 (chloride resistance)

Martensitic stainless steels are mostly of chromium (generally 12-18%) with low carbon in content but are unique in that the steel can be hardened by heat treatments. This type of stainless steel is known for very good strength, wear resistance, and moderate corrosion resistance. They are used in applications such as cutlery, surgical instruments, and turbine blades. A very popular martensitic grade is 410 that has good strength and corrosion resistance at quite a low price. At the same time, 420 finds use in knives and medical instruments because of its ability to be heat treated to a very hard state. Gains in hardness always come with losses in corrosion resistance; therefore, martensitic steels tend to have lower corrosion resistance than other types of stainless steels, austenitic, or ferritic.

Ferritic stainless steels consist of iron-chromium alloys with chromium content usually between 10.5 and 30% and low or zero amounts of nickel. In return for not being hardenable by heat treatment, ferritic stainless steels forgo a portion of their strength and gain ductility and toughness. A key advantage of this steel lies in its relatively good resistance to stress corrosion cracking, and it comes at a low price mainly due to the low content of nickel. Grade 430 belongs to the most popular ones and finds use in architecture and kitchen applications. Grade 434, on the other hand, has a much higher resistance to chlorides and saltwater environments. Ferritic stainless steels suit mildly corrosive environments, hence being extensively used in automotive trims, interior and exterior decorative panels, as well as equipment frequently exposed to atmospheric or mild chemical environments.

Duplex vs. Austenitic Stainless Steels

When observing differences between duplex and austenitic stainless steel, it becomes important to consider their compositions and mechanical properties with respect to the fields of application in order to identify what is most appropriate for any specific set of requirements.

Duplex Stainless Steels

- Austenite + ferrite microstructure

- 19-28% chromium, 4.5-8% nickel

- Up to 5% molybdenum

- Double the strength of austenitic grades

- Excellent stress corrosion resistance

Applications: Chemical plants, offshore oil platforms, desalination

Austenitic Stainless Steels

- 8-12% nickel content

- 16-26% chromium

- Superior corrosion resistance

- Excellent ductility and weldability

- Highly formable and fabricable

Applications: Food processing, medical instruments, decorative architecture

Duplex stainless steels derive their name from a two-fold nature: combined with the austenite in terms of microstructure, its mixture produces very high strength and very good resistance to stress corrosion cracking (approximately double the strength of conventional austenitic stainless steels such as 304 or 316). Duplex stainless steels usually have a balanced composition of chromium (19-28%), nickel (4.5-8%), and molybdenum (up to 5%) with small amounts of nitrogen that enhance corrosion resistance and mechanical properties. These steels are, therefore, well suited for use in harsh environments, including chemical process plants, offshore oil platforms, and desalination systems.

On the other hand, austenitic stainless steel is essentially well known for superior corrosion resistance, ductility, and weldability. Such grades as 304 and 316 have relatively high nickel content (8-12%) and chromium (16-26%), which makes them suitable to perform well in various corrosive environments, including acidic and marine environments. Although these steels are not as resistant as duplex steels, they are much more formable and much easier to fabricate. Thus these steels are widely used in food processing equipment, medical instruments, and decorative architecture.

Advantages and Disadvantages of 434 Grade Steel

Grade 434 stainless steel provides good corrosion resistance, especially concerning chloride stress and saltwater corrosion, hence it is adequate for marine-type applications. It has good tensile strength and some degree of heat resistance. Its disadvantage includes less ductility, as compared to austenitic steels, and ability to withstand extreme heat somewhat can be restrictive in certain high-temperature environments where the behavior might be detrimental.

✓

Advantages

- Excellent corrosion resistance against chlorides and saltwater

- High tensile strength: 450-620 MPa

- Good yield strength: 280 MPa

- Heat resistance up to 815°C (1500°F)

- Cost-effective due to low nickel content

- Good formability and fabrication properties

- Low maintenance requirements

- Oxidation resistance at elevated temperatures

⚠

Limitations

- Lower corrosion resistance compared to grades 316/304 in acidic environments

- Reduced ductility compared to austenitic steels

- Limited toughness at cryogenic temperatures

- Susceptible to grain growth during welding

- May require post-weld heat treatment

- Lower work hardening ability than austenitic grades

- Limited use in extensive forming operations

High Strength and Corrosion Resistance

In the 434 grade stainless steel, a good combination of high strength and high corrosion resistance is exhibited, thus allowing it to be considered for various applications. It is the added molybdenum content that helps it resist pitting and crevice corrosion where the material is exposed to chlorides or other aggressive agents. Therefore, it will see expansive application in industrial, marine, and automotive environments.

Its mechanism, being ferritic, also offers better mechanical properties, such as tensile strength, and long service life. Test methods show that 434 stainless steel has a tensile strength of about 450-620 MPa and yield strength of 280 MPa, which is sufficient to ensure structural reliability under demanding conditions. Besides, it has good resistance to oxidation at high temperatures, where it performs well up to about 815°C (1500°F).

Limitations and Considerations for Use

Despite its numerous advantages, Grade 434 stainless steel has certain limitations and several factors need consideration when differentiating this material for particular applications. One limitation is the corrosion resistance being inferior, compared to higher-grade stainless steels such as 316 or 304, especially in highly acidic, chloride-rich environments. For instance, exposure to seawater or more rigorous industrial chemicals could eventually lead to some degree of localized corrosion or pitting.

Secondly, with its moderately attributable ductility and toughness at cryogenic temperature levels, this steel may pose somewhat severe limitations for use in extreme low-temperature applications. Moreover, since Grade 434 stainless steel is ferritic, it is susceptible to grain growth at elevated temperatures when welded, which could disadvantageously affect the mechanical properties of the weld area and necessitate post-weld heat treatment for a consistent finish.

By far, the next limitation: Grade 434 is lower in work hardening than austenitic grades; hence use could be limited where extensive forming or drawing techniques are required. The engineer, when designing with this particular material, must weigh carefully all the mechanical demands of the project to ensure compatibility.

Reference Sources

-

Steel Pro Group

This source provides an overview of the properties, fabrication, and advantages of Grade 434 stainless steel, emphasizing its corrosion resistance and heat tolerance.

Source Link -

AZoM (Materials Science)

AZoM offers a comprehensive article on the composition, properties, and performance of Grade 434 stainless steel, including its similarities to other grades.

Source Link -

Xometry Resources

Xometry discusses the uses, composition, and properties of Grade 434 stainless steel, highlighting its suitability for applications requiring durability and stability.

Source Link

Frequently Asked Questions (FAQs)

What is grade 434 stainless steel and what are its usages?

Grade 434 stainless steel is a ferritic stainless steel that provides good corrosion resistance mainly with mild acids and alkali. It finds uses in kitchen utensils, automotive parts, and marine applications given its strength and durability.

What are the different grades of stainless steel available?

The different grades of stainless steel include austenitic, ferritic, martensitic, and duplex stainless steels. Each grade varies in properties and is employed for various applications in food processing, marine environments, and chemical processing.

What is the maximum operating temperature of grade 434 stainless steel?

The maximum operating temperature for grade 434 stainless steel usually ranges around 800°C, though the nature of the application and environment needs to be given primary concern since certain chemicals might hamper its performance in high-temperature conditions.

What are the grades of stainless steel with varying degrees of corrosion resistance?

Corrosion resistance varies greatly with stainless steel grades. For example, austenitic stainless steels such as grade 304 and 316 exhibit a greater resistance to corrosion when compared to ferritic grades such as grade 430 and 434. Choosing a particular grade depends on the environmental conditions and the nature of chemical exposure.

What is the importance of chromium and nickel in stainless steel alloys?

Chromium and nickel play a significant role in the composition of stainless steel alloys. Chromium is responsible for the corrosion resistance, and nickel helps to make the metal tough and ductile. Usually, a steel with a higher chromium and nickel content, such as grade 316, can resist another environment much better than those containing less chromium and nickel.