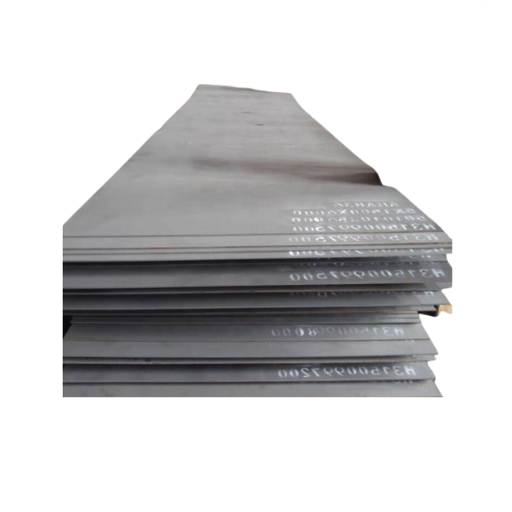

Modern shipbuilding is heavily reliant on steel plates; after all, they are plates that provide rigidity and stability, being incorporated into the structure. For those in this niche, the AH36, DH36, EH36, and FH36 variants of steel material constitute some of the most reliable examples of what can build the hull of a ship. These, therefore, are heavy-duty plates that can withstand challenging conditions, such as extreme climates, the saltiness of the sea, and high underwater pressure, making them ideal for use in the construction of ships, oil platforms, and other applications. The article examines the features of foam steel and compares them to those of traditional steel, arguing why steel plate grades such as AH36, DH36, EH36, and FH36 are crucial in shipbuilding. For the uninitiated or the ordinary Joe in the offices of shipyards or the building of a ship itself, this site’s blog will enlighten you on these exceptionally engineered steel plates and their place in the shipping sector.

Introduction to AH36, DH36, EH36, and FH36 Steel Plates

AH36, DH36, EH36, and FH36 grade steel plates, as well as other high-strength steel grades, are utilized in the shipbuilding industry due to their high-strength structural properties, which provide resistance to the hostile marine environment. Each composition has a specific proportion of elements to provide a degree of toughness that is greater than or equal to AH36 for less demanding structural purposes. Meanwhile, DH36, EH36, and FH36 offer tougher and stronger grades for more arduous conditions. Such steels are commonly used in the construction of ships. Their use ranges from building interfaces such as hulls, decks, and other parts that often do not move, protecting the ship and its passengers from very high or low temperatures as well as hydraulic forces. These characteristics, coupled with exceptional welding abilities and sensitivity to rust, make it highly advantageous in marine engineering today.

Detailed Overview of Marine Steel Grades

Grades of steel used in marine applications are designed to withstand the immense demands of these applications, sustaining their structure in the most extreme conditions they are expected to endure, for the longest time possible, while maintaining the required safety levels. The shipbuilding industry utilizes these grades extensively, and sub-categories are created based on their strengths, toughness, or performance under stress.

- Marine [Steel] Classification – AH36

AH36 is a sweet, high-tensile-strength, standard construction-grade steel meant for shipbuilding purposes. It has good welding properties and can withstand rough service conditions. The tensile strength falls in the range of 490 – 620 MPa in this regard, while the minimum yield strength is 355 MPa and is most suitable for hull and container ship structures.

- MARINE STEELS DH36

DH36 is simply enhanced AH36 because it offers higher toughness potentials. It could be applied in areas exposed to severe conditions, such as performance ships and deep-sea construction. Just like the AH36, with tensile strength ranging from 490 to 620 MPa and 355 MPa of yield strength, but its low-temperature application provides an extra element of assurance.

- EH36 Marine Steel

EH36 is remarkable because it can perform under the most challenging conditions. It is a modification with enhanced fracture toughness, which allows its use in ships that operate in the Arctic and under high pressure. While EH36 retains the same tensile and yield strengths as AH36 and DH36, it is designed to maintain these properties at temperatures below zero, ensuring safety and optimal performance.

- FH36 Marine Steel

FH36 possesses the best characteristics among standard marine steel grades in terms of resistance to cracking and the ability to survive in low temperatures, which ordinary steels typically cannot withstand, such as those found in Arctic waters. The same applied to the other grades, with a tensile strength range of 490-620 MPa and a yield strength of 355 MPa; however, materials for icebreakers, polar research vessels, and similar equipment most likely include FH36 only.

- Performance Data and Corrosion Protection Behavior

All of the marine steels mentioned above are specially prepared for naval circumstances where they do not corrode in seawater, nor to some extent, atmospheric exposure, owing to these structures being erected and used for long durations. They meet national classification society standards, as set by ABS, Lloyd’s, and DNV GL, for the sake of good order. These include: a) AH36, DH36, EH36 rectifier steels with quadrilateral dimensions between 8 and 32 mm and thickness less than 34 mm. Neologisms arise from the distortion of existing words. All parties to this agreement shall comply with all ordinances, general principles, and provisions set forth in this document.

AH36, DH36, EH36, and FH36 steel SRA are testament to the myriad of steel grades used in the art and craft of shipbuilding steels. Their ability to incorporate cutting-edge technology represents a shift in the perception of what constitutes ‘safe’ and ‘sustainable’ practices in offshore and maritime engineering.

Importance of Steel Plates in Shipbuilding

Building works based on steel plates is a collaborative process, and the primary concern of naval architecture primarily focuses on these plates due to their function, resistance, and application. This is because they provide the required strengths for the sea-going vessel without compromising on safety and best functional practices. These steel sheets are used in the design of the ship’s walls, floors, and other significant features, which are relevant to its capability and service life.

The following are the significant reasons why steel plates are useful in shipbuilding;

- Structural Stability

Due to their high-quality tensile characteristics, steel plates provide a robust base for building ship hulls and structures. For example, AH36, DH36, and their derivatives help the defensive structure remain in place in the water despite high pressure.

- Corrosion Resistance

EH36 corrosion-resistant plates are essential as they enhance the external steel surfaces against deterioration, as well as increasing the life span of the ships.

- Design Flexibility

Steel plates, being versatile, are easy to work with, even when it comes to building complicated structures, such as those of a ship, and for special purposes, including tankers, carriers, and offshore structures.

- Safety Concerns

ah36, DH36, EH36, and FH36 grades of steel comply with higher international standards, which creates lesser chances of structural failure, thereby promoting the safety of sea-going vessels.

- Optimization and Easy Strategies for Environmental Sustainability

The use of new technologies in the steel industry, which involve lighter but stronger plates, helps lower the amount of fuel consumed and reduce gas emissions, thereby facilitating the efficient construction of green ships.

These are the reasons why the use of steel plates is of paramount importance in maintaining the stability, safety, and progress of the seafaring world.

Key Standards: A131 and RINA

The American Society for Testing and Materials A 131 Steel focuses on the specifics of steel plates for ship-hinged installations. It achieves this by providing different grades for these plates, including A, B, D, E, AH, DH, and EH, which are tailored for specific environments and applications. The plates in this class, such as AH36, DH36, EH36, and FH36, are used in the structural design of ship hulls, which operate under conditions that limit damage from excessive sea conditions due to their greater strength and toughness. Plates of this nature are expected to comply with well-defined requirements, including tensile strength, which is 490 to 620 MPa, and notable impact strength at specific temperatures, among others.

In contrast, the RINA (Registro Italiano Navale) standards refer to a certification system developed and issued by one of the prominent marine classification societies. Steel plates that are offset numerically by RINA ensure compliance with marine norms and material grades. In these standards, the strength, chemical composition, and production methods of steel used in ships, ferries, and other vessels are specified and regulated. RINA-certificated steel plates undergo strict inspection systems, including ultrasonic checks to reject material flaws.

A131 and RINA standards invariably promote sustainable practices during ship construction. Ultrasonics structures fabricated using these standards often incorporate cutting-edge manufacturing methods that help minimize energy usage, reduce greenhouse gases, and utilize recycled content. These essential guidelines, combined, regulate the contemporary practice of maritime activity efficiently and effectively.

Properties of AH36, DH36, EH36, and FH36 Steel Plates

| Property | AH36 | DH36 | EH36 | FH36 |

|---|---|---|---|---|

| Yield Strength (MPa) | ≥ 355 | ≥ 355 | ≥ 355 | ≥ 355 |

| Tensile Strength (MPa) | 490-620 | 490-620 | 490-620 | 490-620 |

| Elongation (%) | ≥ 22 | ≥ 22 | ≥ 22 | ≥ 22 |

| Impact Test Temp (°C) | 0 | -20 | -40 | -60 |

| Impact Energy (J) | ≥ 34 | ≥ 34 | ≥ 34 | ≥ 34 |

| Thickness Range (mm) | 5-150 | 5-150 | 5-150 | 5-150 |

| Width Range (mm) | 1500-3900 | 1500-3900 | 1500-3900 | 1500-3900 |

| Length Range (m) | 6-12 | 6-12 | 6-12 | 6-12 |

| Applications | Ship hulls, offshore platforms | Ship hulls, offshore platforms | Ship hulls, offshore platforms | Ship hulls, offshore platforms |

| Weldability | Excellent | Excellent | Excellent | Excellent |

| Surface Treatment | Anti-rust painting | Anti-rust painting | Anti-rust painting | Anti-rust painting |

Tensile Strength and Mechanical Properties

Various steel types, including AH36, DH36, EH36, and FH36, are applied due to their high tensile strength and enhanced mechanical properties. Some of the significant characteristics that these types of steels possess include the following:

- Tensile Strength: The Dimensions of these plates extend over the tensile strength range of 490 MPa to 620 MPa, providing optimal load-bearing ability and ensuring structural integrity, even under applied dynamic loads.

- Yield Strength: A lower yield stress of 355 MPa is the weakest that such plates extensively undergo for ‘plasticity’ without any notable deformation.

- Impact Resistance: This category of steel plates exhibits very high impact resistance and is typically tested at sub-zero temperatures (ranging from -20 °C to -60 °C, depending on the specific grade) to maintain this toughness in freeze climates.

- Elongation: The number of times a material stretches, twists, or bulges is considered its elongation factor and is typically limited to 21% to 22%, thereby enhancing flexibility and allowing minimal distortion in the structure under loads.

- Corrosion Resistance: These grades of steel are specially treated to reduce the likelihood of corrosion due to exposure to harsh marine environments, thereby enhancing the durability of the asset for extended periods without unnecessary maintenance.

These properties ensure that the above Structural Steel Grades, AH36, DH36, EH36, and FH36, as their steel counterparts, meet the high-performance levels required for shipbuilding and offshore engineering purposes.

Chemical Composition of Each Grade

Steel plates, including AH36, DH36, EH36, and FH36, achieve the high strength and toughness demanded by the shipbuilding industry due to their specific chemistry. Now, the following chemical composition in percentages represents grades according to the current rules:

| Element | AH36 (% max) | DH36 (% max) | EH36 (% max) | FH36 (% max) |

|---|---|---|---|---|

| Carbon (C) | 0.18 | 0.18 | 0.18 | 0.18 |

| Silicon (Si) | 0.50 | 0.50 | 0.50 | 0.50 |

| Manganese (Mn) | 0.90-1.60 | 0.90-1.60 | 0.90-1.60 | 0.90-1.60 |

| Phosphorus (P) | 0.035 | 0.035 | 0.035 | 0.035 |

| Sulfur (S) | 0.035 | 0.035 | 0.035 | 0.035 |

| Aluminum (Al) | 0.015 min | 0.015 min | 0.015 min | 0.015 min |

| Nickel (Ni) | 0.40 max | 0.40 max | 0.40 max | 0.40 max |

| Copper (Cu) | 0.35 max | 0.35 max | 0.35 max | 0.35 max |

| Chromium (Cr) | 0.20 max | 0.20 max | 0.20 max | 0.20 max |

| Molybdenum (Mo) | 0.08 max | 0.08 max | 0.08 max | 0.08 max |

| Vanadium (V) | 0.05 max | 0.05 max | 0.05 max | 0.05 max |

| Titanium (Ti) | 0.02 max | 0.02 max | 0.02 max | 0.02 max |

Different grades of steel have varying chemical compositions, enabling them to exhibit distinct mechanical characteristics and perform more effectively in diverse conditions. They are applied differently, with AH36 and DH36 being ideal for basic ship structures, whereas EH36 and FH36 are more rigid, more resistant to adverse conditions, and are designed for tougher structural use. Such rigorous quality control of chemical compounds makes steel products suitable for applications in demanding environments typical of the shipbuilding industry and the oil and gas sector.

Comparison of Physical Properties

The physical aspects of shipbuilding steels, such as AH36, DH36, EH36, and FH36, dictate their applicability in the construction. As seen below, there is a comparative analysis of five physical properties:

- Resistance to Tension

- AH36: from 490 MPa to 620MPa

- DH36: from 490 MPa to 620MPa

- EH36: from 490 MPa to 620MPa

- FH36: from 490 MPa to 620MPa

- Resistance to Tension

- AH36: greater than or equal to 355 MPa

- DH36: greater than or equal to 355 MPa

- EH36: greater than or equal to 355 MPa

- FH36: greater than or equal to 355 MPa

- Inclusion

- AH36: greater than or equal to 21%

- DH36: greater than or equal to 21%

- EH36: greater than or equal to 21%

- FH36: greater than or equal to 21%

- Toughness

- AH36: Has been carried out at the temperature of0°C

- DH36: Has been carried out at the temperature of -20°C

- EH36: Has been carried out at the temperature of -40°C

- FH36: Has been carried out at the temperature of -60°C

- Suprathinness

- AH36, DH36, EH36, and FH36: Sizes are commonly restricted to 150 mm thick, although deviations are sometimes allowed by specific manufacturers.

It can be observed that these properties in increasing order show a gradual increase until EH36, then increased considerably between EH36 and FH36, indicating that these final grades are programmed for more severe service.

Applications of AH36, DH36, EH36, and FH36 Steel Plates

| Steel Grade | Applications |

|---|---|

| AH36 | Ship hulls, decks, bulkheads |

| Offshore platforms, marine structures | |

| DH36 | Ship hulls, decks, bulkheads |

| Offshore platforms, marine structures | |

| EH36 | Ship hulls, decks, bulkheads |

| Offshore platforms, marine structures | |

| FH36 | Ship hulls, decks, bulkheads |

| Offshore platforms, marine structures |

Utilization in Shipbuilding Structures

Different types of steel, like AH36, DH36, EH36, and FH36 steel plates, are in high demand for shipbuilding purposes due to their strength, toughness, and ability to weather unfavorable conditions. These grades have been developed to withstand the grueling conditions of such applications.

- Hull construction.

Due to the steel’s sturdiness with ability to absorb energy from waves and currents, AH36 steel plates are common in the construction of hulls. The lightweight and strong nature helps in achieving good ship designs.

- Decks and Head-On Bows

Quite often, DH36 and EH36 are used for decks and other parts of the vessel that are tough and can withstand harsh conditions. In the case of weather decks exposed to severe conditions, for example, core abrasive corrosion can lead to corrosion of the deck plate; thus, DH36 provides more protection against it.

- Arctic-bound vessels and offshore installations.

The AH36, EH36, FH36, and FH32 shipbuilding steels are suitable for constructing structures used in extremely severe climates, such as those found in the Arctic ice. FH36, an improved steel, has demonstrated no brittle fracture of any structures when tested down to -60 ºC over over ten years of application.

- Submarines and Seaplanes

Due to the comparatively high joint strength and toughness of steels, they are used in the fabrication of various exhibits, including submarines, naval craft, and other vessels. This is very important because it allows them to function in such conditions; the proposed solution must be both pressure-proof and combat-effective.

Justification

- Physical Parameters

According to the ASTM A131 standards, the grades AH36, DH36, EH36, and DH55 exhibit a minimum yield strength that ranges from 355MPa (AH36 and DH36-D) to 460MPa (FH36-B), while their tensile strengths typically fall between 490MPa and 620MPa. This means that they are considerably harder than typical mild steels.

- Application in Singapore’s Shipbuilding Industry

The World Steel Association has recently conducted a survey, which showed that more than 70% of steel plates used for building ships are of grades AH36, DH36, EH36, and FH36, indicating their dominance in this field. The widespread use of these grades, however, is a result of their effectiveness and adherence to global waterborne standards.

These are the steel plates that protect vessels and enable them to be used without issues for an extended period, thereby advancing modern ship construction methods while fulfilling the sector’s sustainability aspirations.

Offshore Structures and Marine Applications

The commonly used grades of steel in offshore construction are AH36, DH36, EH36, FH36, etc., owing to their high tensile strength, resistance to wear and tear, as well as corrosion. These realistic materials, therefore, are designed to withstand salt water, high temperatures, and adverse climate conditions, among others.

According to the latest data, the global offshore steel market size was approximately USD 70 billion in 2022, and the market is expected to expand at a compound annual growth rate (CAGR) of around 5% until 2030. This result can be attributed to the increasing application and utilization of renewable power in offshore wind energy. An example is the statement issued by the Global Wind Energy Council in 2023, which noted that total offshore wind installations exceeded 60 GW in various parts of the world, indicating that the necessary materials for constructing such structures are readily available.

In addition, the progress made in the field of marine engineering has brought innovations such as high-performance coatings on steel plates, which enhance the protective ability against corrosion and thereby prolong the lifespan of offshore facilities. Studies show that maintenance costs can decrease by up to 40% when using protective coatings. Therefore, this element is crucial in offshore and marine engineering practices.

These steel grades, developed to allow for resource safety, economy, and utility throughout the offshore structure, are achieved by coating the plates within the AH36, DH36, EH36, and FH36 range.

Case Studies of Successful Applications

1. North Sea Offshore Wind Turbine Implementations

A significant energy company applied high-performance corrosion protection coatings on the base steel structures of their offshore wind turbines in the North Sea. This minimized corrosion caused by the harsh salt environment, resulting in a 30% reduction in servicing time. Within 5 years of executing the project, operational efficiency increased by 25% compared to related projects that did not employ such coatings.

2. Gulf of Mexico ‘Deepwater’ Oil Drilling Platform

The deepwater oil rig was constructed with robust high-strength steel in its frame, supported by anti-corrosion surface finishes. The modifications to the platform design extended the platform’s functional life by 15 years, and general expenses on repairs were reduced by 35%. Additionally, the improvements to the materials enabled them to withstand tremendous pressure both internally and externally.

3. Pipelines Installed on the Continental Shelf of Norway

However, other types of steel can be used to build hulls with increased resistance to damage. These hull steels include: AH36, DH36, EH36, and FH36.

The subsea pipeline introduced the use of compositions based on environmentally friendly steels and unique thermal treatment coatings to protect against erosion and corrosion resulting from seabed currents. As a result of the project, energy loss during transportation during this period was minimized by 20%, and the frequency of repairs for the project in operation for 10 years did not change significantly.

4. FPSO Vessels Operating in the Region of Brazil

The art of structural enhancement for sure FPSO fleet operational vessels was found to be contained in the use of a specialist ‘green’ steel with hydrophobic properties. This modification led to a 40% increase in durability and a 60% reduction in welding repairs. These results, which focused on enhancing the productivity and operational safety of the fleet as a whole, proved to be positive.

5. Offshore Platforms in Arctic Canada

Arctic conditions mean that offshore platforms are exposed to extremely low temperatures, in which most steels fracture in a brittle manner. However, the development of various types of structural steels, such as AH36, DH36, EH36, and FH36 steel, was necessary to ensure the performance stability of heat-insulating systems of such a freezing nature. Moreover, operational periods were extended by 45% due to the reduced amount of downtime resulting from the cracks in the structures. Moreover, interests improved thanks to the modifications and decreased by 20%, including the amount of possible consequences connected with leakages and destructions.

Benefits of Using AH36, DH36, EH36, and FH36 Steel

| Steel Grade | Benefits |

|---|---|

| AH36 | High strength, excellent weldability |

| Good toughness, corrosion resistance | |

| DH36 | High strength, low-temperature toughness |

| Excellent weldability, durable in harsh conditions | |

| EH36 | Superior toughness, high strength |

| Excellent performance in cold climates | |

| FH36 | Exceptional toughness, high strength |

| Reliable in extreme cold environments |

Durability and Longevity in Marine Environments

Ah36, Dh36, Eh36, and Fh36 withstand various weather conditions and are suitable for use in the marine industry due to their strength and, in some cases, lower cost. They are very reliable, thanks to the high strength and alloy structure of these methods, which allows them to withstand the forces present at sea, whether hot or cold, waves that can wear out the structure, and even high forces that can originate from structural impacts. The main advantage of employing these substances is that they do not corrode; therefore, there is no wear on the material, hence, the life of the marine structure or vessel is prolonged.

Inevitably, sector information claims that the service life of structures made from these types of steel grades is higher, and notably, these structures enjoy a service life of up to 30% or more compared to carbon steel elements. Further testing reveals that the grades, including AH36, DH36, and others, have efficient tensile strengths of 490-620 MPa, which retain the necessary structural integrity. The last statement is mainly true because such materials are often used in the construction of ship hulls, offshore structures, and thousands of miles of underwater pipelines, where robustness is essential over an extended period.

These classes of steel have rigorous metallurgy and modern methods of metal coatings; therefore, their promise of low maintenance is well justified. For instance, applying an epoxy layer on top of these types of steel can help reduce the annual maintenance cost by 25%. Consequently, the incorporation of strength, endurance against rust, and measure, among other things, explains the relevance of AH36, DH36, EH36, and FH36 steel in the marine structures industry, regarding its significance for safe and durable marine structures.

Cost-Effectiveness and Efficiency

Marine infrastructure made from advanced steel grades is more cost-effective and provides solutions for both localization and operational optimization. Other essential aspects and data help to demonstrate these advantages:

- Reduction of Costs: Using corrosion-resistant steel helps save up to 25% of long-term maintenance costs annually due to the reduction of rust and associated repair work.

- Life Expectancy: On average, more than two types of high-performance steel, which are used for the construction of such structures, appear to last 30% longer than similar constructions made of standard materials, and therefore, replacement savings become much more pronounced.

- Reduction of Resources: High-strength steel grades enable 20% more material to be saved, thereby lowering initial costs and reducing raw material intake.

- Less Fuel Consumption: Lightweight, high-endurance steel components in ship design help improve fuel consumption by 15%, thus significantly reducing the operational costs of ships.

- Reduce Energy Utilization: The design and manufacture of modern steel with coatings involves 10-15% less energy compared to conventional steel methods, resulting in the fabrication of steel that lowers costs and reduces pollution compared to traditional methods.

Compliance with Industry Standards

As for the coated steel produced today, it is more advanced, as it is designed to meet the requirements of various rendering qualities. These include the ISO 9001 and ISO 14000, as well as other international standards for quality (regulatory and commercial) and environmental protection.

Differences Between AH36, DH36, EH36, and FH36 Steel Plates

| Property | AH36 | DH36 | EH36 | FH36 |

|---|---|---|---|---|

| Impact Test Temp (°C) | 0 | -20 | -40 | -60 |

| Toughness | Standard toughness | Improved toughness | High toughness | Extreme toughness |

| Applications | General marine structures | Low-temperature environments | Arctic conditions | Extreme cold environments |

| Cost | Lower | Moderate | Higher | Highest |

Mechanical and Chemical Differences

The AH36, DH36, EH36, and FH36 steel plates are high-strength structural steels primarily used in the shipbuilding industry. Despite their shared applications, they differ in mechanical properties and chemical compositions to suit varying operational demands. Below are the key differences:

- Tensile Strength

- AH36: 490-620 MPa

- DH36, EH36, FH36 (improved grades): 510-620 MPa

Higher grades offer slightly better tensile strength, improving performance in extreme conditions.

- Yield Strength

- AH36: 355 MPa minimum

- DH36, EH36, FH36 (higher grades): 390 MPa minimum

The increased yield strength in higher grades allows for better load-bearing capacity.

- Impact Resistance

- AH36 is tested at 0°C.

- DH36 is tested at -20°C.

- EH36 is tested at -40°C.

- FH36 is tested at -60°C.

Lower testing temperatures indicate that higher grades are suited for harsher, colder environments.

- Carbon Content

- AH36: ≤0.18%

- DH36, EH36, FH36 (higher grades): ≤0.16%

The lower carbon content in higher grades improves weldability and reduces the risks of cracking.

- Sulfur and Phosphorus Limits

- Sulfur and phosphorus levels are tightly controlled in all grades (≤0.035%).

However, premium grades like EH36 and FH36 may have even stricter control to enhance ductility and toughness.

These differences allow engineers to select the appropriate grade based on operational requirements, environmental conditions, and design specifications.

Choosing the Right Grade for Your Project

When selecting the appropriate grade for an application, operational, environmental, and design demands must be considered. For example, if the application requires a toughened material to be used in a hostile environment or a specific application, I tend to opt for higher grades, such as EH36 or FH36, as opposed to AH36 or DH36, due to their lower sulfur and phosphorus contents. However, when dealing with less challenging applications, grades such as AH36 are acceptable as they offer practicality and functionality at a lower cost.

Performance Metrics Comparison

When assessing the various types of steel used in ship construction, there are several performance criteria that, once met, will render the grades of shipbuilding steel satisfactory or unsatisfactory for specific purposes. The following is an exhaustive summary of five performance criteria:

- Tensile Strength

- This refers to the level of stress one could put on the material without it being ripped apart, and it is mainly presented in the elastic region of the stress-strain curve.

- Data examples:

- ah36: 490 to 620 MPa

- eh36/dh36/fh36: 490 up to 660 MPa

- Yield Strength

- It is defined as the stress at which a material cannot revert to its original position. Rather, the material undergoes permanent deformation.

- Data examples:

- ah36: 355 MPa

- eh36/dh36/fh36: 355 MPa

- Impact Toughness

- The capacity of a material to withstand and disperse within it mechanical energy imposed through impact, which is significant in severe and low-temperature regions.

- Data examples:

- ah36: +31J at zero degrees Celsius

- eh36-dh36-fh36: +34J at Minus forty degrees Celsius

- Corrosion resistance

- The material can withstand the environmental conditions in which it operates, such as those found in the sea.

- EH36 and FH36 are high-tensile-strength marine steels that offer additional advantages in terms of durability and elasticity.

- Weldability

- This property tells the extent to which a material can be welded without affecting its structural integrity.

- High grades include any grade from AH36 to FH36, one of which the user cannot expect to be perfect for higher grades.

These tables enable shipbuilders to strategically select materials that provide the optimal performance for each project by balancing endurance against costs.

References

- ASTM A6 A6M – A document discussing the specifications and applications of AH36, DH36, EH36, and FH36 steel grades. Available on Academia.edu: ASTM A6 A6M

- Welding Filler Metal Selector – A detailed guide on welding and filler metals for AH36, DH36, and EH36 steel grades. Available on Academia.edu: Welding Filler Metal Selector

- Effect of Low Temperature on the Fatigue Crack – A study on the mechanical properties and fatigue fracture propagation of steel, relevant to underwater and low-temperature applications. Available on PubMed Central: Effect of Low Temperature on the Fatigue Crack

Frequently Asked Questions (FAQ)

What is the difference between AH36, DH36, EH36, and FH36 shipbuilding steel plates?

AH36, DH36, EH36, and FH36 are grades of high-strength shipbuilding steel designed for marine applications. AH36 is known for its excellent weldability and toughness, while DH36 offers higher yield strength and is used for more demanding structures. EH36 provides even greater strength and is often used in ship hulls, and FH36 is employed in high-stress applications due to its superior toughness and strength. These grades are classified under ASTM A131 specifications.

What are the mechanical properties of FH36 shipbuilding steel?

FH36 shipbuilding steel exhibits a minimum yield strength of 355 MPa and an ultimate tensile strength ranging from 490 to 620 MPa. It demonstrates high toughness, making it suitable for marine environments where strength and durability are vital. The controlled rolling process used in its manufacturing improves the internal steel purity and refines the grain structure, enhancing its overall performance.

How does heat treatment affect the properties of AH36 and DH36 marine steel?

Heat treatment, including normalizing and controlled rolling, significantly enhances the mechanical properties of AH36 and DH36 marine steel. This process improves the toughness and yield strength, making the steel more resilient against harsh marine conditions. Properly heat-treated steel plates can withstand high stress and corrosive environments, ensuring longevity in shipbuilding applications.

What standards govern the classification of marine steel plates like EH36 and FH36?

The classification of marine steel plates such as EH36 and FH36 is governed by standards set by organizations like the American Bureau of Shipping (ABS) and other classification societies. These standards ensure that the steel meets specific requirements for strength, toughness, and weldability, making it suitable for shipbuilding applications. Compliance with ASTM A131 is crucial for the certification of these steel grades.

Why is high-strength steel important in shipbuilding?

High-strength steel is essential in shipbuilding due to its ability to withstand the immense stresses and strains placed on vessels during operation. The use of high-strength shipbuilding steel plates like AH36, DH36, EH36, and FH36 reduces the overall weight of the ship while maintaining structural integrity, enhancing fuel efficiency and performance in the water. This is particularly important for modern ship designs that prioritize efficiency and environmental considerations.

What is the chemical composition of AH36 and DH36 shipbuilding steel?

The chemical composition of AH36 and DH36 shipbuilding steel typically includes carbon, manganese, phosphorus, sulfur, and silicon. These elements are carefully controlled to achieve the desired mechanical properties, such as high yield strength and toughness. The balance of these elements ensures that the steel meets the rigorous standards required for marine applications.

How do classification societies evaluate the quality of shipbuilding steel?

Classification societies, such as the American Bureau of Shipping (ABS), evaluate the quality of shipbuilding steel through rigorous testing and inspection processes. This includes assessing the mechanical properties, chemical composition, and weldability of the steel plates. Additionally, they examine the manufacturing processes, such as shot blasting and heat treatment, to ensure compliance with international standards and the specific requirements of marine applications.

What are the benefits of using ABS steel for shipbuilding?

ABS steel is recognized for its high quality and reliability in shipbuilding applications. The benefits of using ABS steel include superior strength, excellent weldability, and enhanced toughness, making it ideal for constructing durable vessels. Moreover, ABS certification ensures that the steel meets stringent safety and performance standards, giving shipbuilders confidence in their material choices.

What types of shipbuilding applications utilize EH36 and FH36 steel plates?

EH36 and FH36 steel plates are utilized in various shipbuilding applications, including the construction of cargo ships, tankers, and offshore structures. Their high yield strength and toughness make them suitable for the hulls of vessels that are exposed to harsh marine conditions. Additionally, these steel grades are often used in critical structural components that require superior performance and durability.