The choice of steel becomes paramount in constructing durable and robust ship structures. AH36, DH36, EH36, and FH36 shipbuilding steel plates are probably the most prized materials in the maritime industry-for they offer great strength and resistance to corrosive influences posed by the marine environment. In this article, we will explore how the unique characteristics of these steel grades contribute to making vessels safer, more efficient, and more durable. Whether an expert in the industry or just being curious, join us in unearthing the criteria that make these steel plates inseparable in present-day shipbuilding and how they help to steer through the smooth and rough weather of the open sea.

Overview of Shipbuilding Steel Plates

Shipbuilding steel plates are specially designed materials used in the construction of ships and other marine structures. These plates are designed to withstand the harsh conditions posed by pressure, corrosive saltwater, and varying temperatures, thereby ensuring the durability and safety of the vessels. They are offered in various grades and thicknesses to suit the specific needs of ship hulls, decks, and internal components. A steel plate with such properties as high strength, corrosion resistance, and weldability would be considered ideal for modern-day shipbuilding work.

Advancements in Shipbuilding Steel

There has been significant growth in shipbuilding steels over the past few decades, primarily driven by advances in metallurgy and increased demand in the global maritime industry. The latest shipbuilding steel types aim to strike a balance between strength, ductility, and durability. For example, some of the more common grades, such as AH36, DH36, and EH36, are high-tensile-strength steels, thereby securing favorable performance factors even in extreme marine conditions. Such steel materials are typically employed in the construction of large commercial vessels, cruise liners, and naval fleets.

Further improvements have made the steel corrosion-resistant and capable of standing against the severe onslaught of marine weathering. Some recent reports suggest a loss of between 30 to 50% in the mechanical properties of maritime structures due to corrosion over time. Hence, the use of premium steel grades resistant to corrosion will immensely help in reducing maintenance costs and enhancing the ship’s lifespan.

Another significant development was the emergence of eco-friendly steel-making technologies. With ever-tightening environmental regulations/modifications, such as the IMO’s sulfur cap regulations, manufacturers are making tremendous efforts to make their production methods carbon-congenial and pollution-friendly. These processes contributed to favoring HSLA steels in modern ship designs, as these steels help reduce weight in vessel fabrication, ensuring that shipbuilders do their share in helping to reduce fuel consumption and subsequent CO₂ emissions.

There has also been a recent increase in the use of lightweight composite materials, supported by shipbuilding-grade steel, to provide additional support for maintaining structural integrity. These would represent a significant stepping stone towards sustainable and energy-efficient maritime design, meeting the ever-increasing requirements of global shipping.

Importance of Steel Grades in Shipbuilding

Steel grades are crucial for any ship being constructed, ensuring it stands the test of time and remains safe. The choice of steel grades will directly influence the vessel’s ability to withstand the challenges of the marine environment, resist corrosion, and maintain satisfactory structural performance under evolving stress conditions. Here is a comprehensive rundown of five steel grades commonly used in shipbuilding and their distinguishing features:

- AH36

- It is a high-strength steel for hull construction.

- Excellent welding qualities make it suitable for assembling larger components.

- Withstands high stresses, more so during rough seas.

- Yield Strength: 355 MPa and Tensile Strength: 490-620 MPa.

- EH36

- Enhanced toughness, especially under the effects of low temperatures.

- For decks, bulkheads, and other primary structural parts.

- Withstand an equivalent yield strength (355 MPa) with tensile strength (490-620 MPa).

- DH36

- Combines very high strength and excellent toughness with weldability.

- Mainly used for ship plates and structural members.

- Grade A Steel

- Basic grade of steel used for ship hull and general structural components.

- For less demanding applications and those where heavy structural stress is not of significant concern.

- Yield Strength of 235 MPa with good corrosion resistance.

- Grade E Steel

- Tenderly tough in unusual conditions of extreme coldness.

- Usually applied to Arctic-class vessels navigating icy waters.

- High durability ensures resistance to cracking under sub-zero temperatures.

Selecting among these steel grades depends on the design requirements of a ship and its intended operational environment, allowing modern ships to remain resilient and perform efficiently.

Key Standards for Shipbuilding Steel Plates

The chief standards specifying shipbuilding steel plates include ASTM A131, ABS, Lloyd’s Register, and DNV GL, which ensure the material’s strength, durability, and suitability for maritime operations.

Properties of AH36, DH36, EH36, and FH36 Steel Plates

AH36, DH36, EH36, and FH36 grades of steel plates are considered high-strength structural steels. These grades share similar properties at their core but differ slightly due to their distinct operating environments.

- Strength: These plates offer high strength, permitting their use for large-sized ships and offshore structures.

- Durability: These steels resist impacts and saltwater weathering exceptionally well.

- Weldability: These steels are readily weldable and can be easily fabricated, facilitating straightforward construction.

- Temperature Resistance: AH36 generally performs well; DH36 and EH36 perform better with reducing temperatures; FH36, however, performs excellently in very low temperatures.

Applying these properties enables the development of robust and dependable shipbuilding projects.

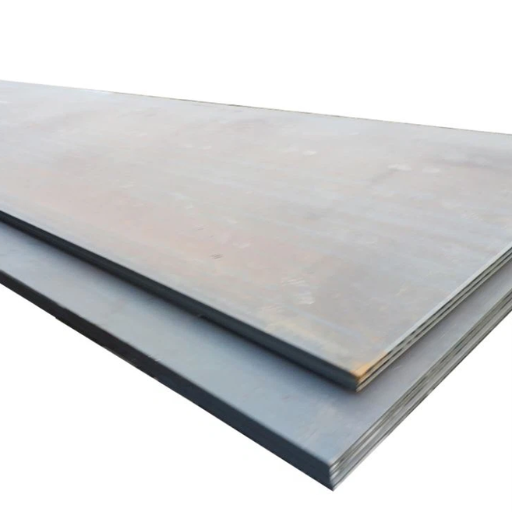

Mechanical Properties and Tensile Strength

The different grades of steel present some possible mechanical characteristics suitable for heavy-duty shipbuilding applications:

- Tensile Strength: These steels of such grades generally have tensile strengths in the range from 490 MPa to 620 MPa, thus allowing the steel to be subjected to significant stresses before it fractures.

- Yield Strength: With a yield strength of at least 355 MPa, these grades can undergo a large amount of strain without any deformation.

- Elongation at Break: These steels exhibit an elongation of 21-23%, indicating significant contraction in another axis and a reduction in dimensions resulting from the applied force.

- Impact Resistance: AH36, DH36, EH36, and FH36 grades demonstrate high values of impact resistance, ensuring that fractures never develop, even under the most severe conditions of use or extremely low temperatures.

- Hardness: The hardness properties contribute to abrasion resistance and provide structural stability, which in turn increases the lifespan of these materials and reduces the frequency of maintenance.

With these properties combined, AH36, DH36, EH36, and FH36 steels exhibit the perfect blend of performance and reliability essential for marine construction works in general.

Comparative Analysis of AH32, AH36, and Other Grades

| Parameter | AH32 | AH36 | Other Grades |

|---|---|---|---|

| Yield Strength (MPa) | ≥ 315 | ≥ 355 | Varies by grade |

| Tensile Strength (MPa) | 440–590 | 490–620 | Varies by grade |

| Impact Test Temp (°C) | 0 | 0 | -20 to -40 (Grade D/E) |

| Thickness Range (mm) | ≤ 150 | ≤ 150 | ≤ 150 |

| Applications | Ship hulls, marine structures | High-stress ship areas | General or specific ship parts |

| Delivery Condition | Hot rolling, normalizing | Hot rolling, normalizing | Varies by grade |

| Rust Protection | Anti-rust painting | Anti-rust painting | Anti-rust painting |

| Chemical Composition | ≤ 0.18% C, Mn 0.7–1.6% | ≤ 0.18% C, Mn 0.7–1.6% | Varies by grade |

| Classification Society | ABS, BV, CCS, DNV, etc. | ABS, BV, CCS, DNV, etc. | ABS, BV, CCS, DNV, etc. |

| Key Difference | Lower strength than AH36 | Higher strength than AH32 | Depends on specific grade |

Impact Resistance and Durability

When comparing different steel grades, such as AH32, AH36, EH36, and FH36, impact resistance and durability are always critical factors to consider in terms of their applicability in severe maritime conditions. Below are five factors that provide a short overview of the impact resistance and durability of these grades:

- High Toughness: These steel grades exhibit very high Toughness, especially at low temperatures, absorbing impact without fracturing.

- Structural Integrity: With higher metallurgical characteristics, these materials maintain their structural integrity at a very high level of stress, making them ideal for ship hulls and offshore platforms.

- Corrosion Resistance: Enhanced corrosion resistance enables longer life in high-chloride or saline environments, thereby reducing the likelihood of structural failure over time.

- Fatigue Resistance: Such grades exhibit excellent fatigue-resisting properties such that even a repetitive load cycle due to waves and fluctuating sea conditions can be resisted.

- Impact Testing Standards: The materials conform to rigorous impact testing requirements, such as Charpy V-notch tests, ensuring they withstand heavy mechanical loading and collision scenarios.

Such characteristics indeed make these steel grades the most eminent solution for such a demanding engineering task as marine construction, where safety and durability are absolute priorities.

Applications of Shipbuilding Steel Plates

The steel plates for shipbuilding primarily go into the construction of various types of marine structures. These include commercial ship hulls, cargo vessels, and passenger ships. Offshore platforms, boats, and oil rigs are other structures on which these are installed. Their superior strength and corrosion resistance ensure they can withstand unfriendly marine environments and provide structural integrity to the marine structures.

Use in Different Types of Vessels

The life of shipbuilding plate steels is embedded in a palimpsest of various vessel designs, each intended for diverse purposes and operational requirements. The following are the five major types of vessels with their associated uses of shipbuilding steel plates in construction:

- Commercial Cargo Vessels

If cargo vessels transport their commodities over longer distances, the need for steel plate construction arises to create a sturdy hull that can withstand heavy loads and rough sea conditions. Hopefully, steel plates such as Grade A or AH36 are used for these purposes.

- Oil Tankers

Oil tankers, owing to their better resistance to corrosion offered by crude oil and the marine atmosphere, require steel plates. Being huge, these ships need thick grades of DH36 and EH36 to maintain their structural integrity.

- Passenger Ships and Cruise Liners

For passenger safety and comfort, the construction of watertight structures and decks utilises high-strength steel plates, often made to international safety standards.”

- Offshore Supply Vessels (OSVs)

These OSVs serve to support offshore oil and gas operations. Steel plates used for their hulls and decks must be exceptionally tough; e.g., AH40-grade plates would endure the stringent conditions of supply tasks.

- Naval Ships

Military and defense vessels require steel plates ofthe highest performance with ballistic resistance grades, like HSLA, that assist in achieving necessary ballistic protection and heavy operational efficiency under extreme conditions.

Specific grades and designs of steel plates are used in each vessel, further expressing the versatility and importance of these materials in the shipbuilding industry.

Role in Marine Structures and Infrastructure

Steel plates are paramount for marine structures and coastal infrastructure that require durability, stability, and resistance to the harsh challenges of the aquatic environment. Below are the five applications and their importance.

- Offshore Platforms

Steel plates serve as a base in offshore oil and gas platforms, providing resistance against the strong ocean currents, high winds, and corrosive effects of saltwater. Typically, high-tensile grades of steel such as API 2W are used in these structures.

- Docks, Warehouses, and Ports

They have steel-based foundations and walls that are resistant to corrosion. Such materials prolong the life of these critical facilities while lessening their requirements for repair and maintenance cost over time.

- Bridges and Connector Infrastructure

Steel plates form the bedrock to make bridges durable enough to cross another body of water. Marine Steel grades, such as ASTM A36 or A514, are primarily used to withstand heavy loads and environmental impacts.

- Submarine Pipelines

Restaurant steel plates should be used for supporting subsea pipelines that transport oil, gas, or water, while being highly resistant to pressure and chemically resistant to corrosion. Grades such as X65 or X70 ensure that these pipelines perform efficiently at great depths.

- Wave Breakers and Gore

Coastal barriers and wave breakers constructed with steel plate reinforcements help protect shorelines from erosion and reduce tidal surges. The existence of this structure is vital for the conservation of shore ecosystems and human habitats.

While these applications elucidate the versatility attribute of steel plates in marine engineering, with weight-tolerance-grade materials, one cannot compromise on robustness and longevity.

Advantages of Using AH36, DH36, EH36, and FH36

| Parameter | AH36 | DH36 | EH36 | FH36 |

|---|---|---|---|---|

| High Strength | ≥ 355 MPa | ≥ 355 MPa | ≥ 355 MPa | ≥ 355 MPa |

| Tensile Strength | 490–620 MPa | 490–620 MPa | 490–620 MPa | 490–620 MPa |

| Impact Resistance | 0°C | -20°C | -40°C | -60°C |

| Thickness Range | ≤ 150 mm | ≤ 150 mm | ≤ 150 mm | ≤ 150 mm |

| Applications | General shipbuilding | Low-temperature areas | Arctic and cold regions | Extreme cold environments |

| Weldability | Excellent | Excellent | Excellent | Excellent |

| Durability | High | High | High | High |

| Rust Protection | Anti-rust coating | Anti-rust coating | Anti-rust coating | Anti-rust coating |

| Classification Society | ABS, BV, CCS, DNV, etc. | ABS, BV, CCS, DNV, etc. | ABS, BV, CCS, DNV, etc. | ABS, BV, CCS, DNV, etc. |

| Key Advantage | General high-strength steel | Low-temp toughness | Arctic-grade toughness | Extreme cold-grade toughness |

Comparative Analysis with Other Materials

In comparison to other materials, such as aluminum and composite fibers, AH36, DH36, EH36, and FH36 steel plates offer superior tensile strength, durability, and cost efficiency. Aluminum, being lighter, does not possess very high resistance to the impacts and stresses expected to be sustained over long periods; hence, steel plates are significantly advantageous in high-demanding marine settings. Conversely, composites resist corrosion but come at stiffer prices and are challenging to repair. These steel grades are perfectly balanced in terms of performance, longevity, and affordability, which makes them the desirable option in pivotal structural and marine engineering projects.

Steel vs. Aluminum in Shipbuilding

| Parameter | Steel | Aluminum |

|---|---|---|

| Weight | Heavier | 30% lighter than steel |

| Strength | High | Moderate |

| Corrosion Resistance | Requires protective coatings | Forms natural oxide layer |

| Cost | Cheaper | More expensive |

| Durability | Excellent abrasion resistance | Less durable |

| Maintenance | High (requires painting) | Low (minimal painting needed) |

| Weldability | Easier to weld | Requires skilled welders |

| Fuel Efficiency | Lower due to weight | Higher due to reduced weight |

| Applications | Large, durable vessels | High-speed, lightweight vessels |

| Resale Value | Moderate | Higher |

Cost-Effectiveness of Steel Plates

Steel plates are regarded as a more cost-effective material for ship construction, offering advantages in terms of price, availability, and durability. Given their long operational life and low maintenance requirements, steel plates tend to be an economical solution for massive marine projects. Here are five reasons explaining why they are economical:

- Lower Raw Material Costs: Steel plates are typically less expensive to produce and procure than other materials, such as aluminum or composites, which reduces the initial material cost in shipbuilding.

- Ease of Fabrication: Steel can be easily welded and formed into complex shapes with minimal need for specialized equipment. This makes fabrication easier and lowers the labor and production costs.

- Long Life and Durability: Steel plates have a long lifespan and can withstand harsh marine climates, resulting in fewer replacements and lower costs in the long run.

- Widespread Availability: Steel is readily available across the globe, ensuring a steady supply and price stability, which are crucial factors in managing the budget for large-scale shipbuilding.

- Recyclability: Being recyclable at the end of life, steel plates help practicing environmentalism while offsetting some associated costs through the recovered value of scrap steel.

Hence, combining the above factors makes steel plates a wise choice for achieving cost efficiency while continuing with eco-friendly shipbuilding.

Long-Term Performance Considerations

The long-term durability of steel plates in shipbuilding makes me concentrate on their corrosion resistance and maintainability. Considered appropriately, these steel plates can withstand the maritime climate, thereby providing them with a good service life. The strength and structural integrity of these steel plates dictate ship safety and reliability for decades through use. Maintenance procedures, such as periodic inspections and overhauls, keep the steel plates in service for many years, making them a sustainable and innovative choice for ship construction.

Current Trends in Shipbuilding Steel

To improve fuel efficiency and reduce emissions, modern shipbuilding is developing high-strength, lightweight steel. To meet stringent environmental restrictions on shipbuilding and to improve ship life, more advanced steel types, such as high-tensile and corrosion-resistant steels, are being increasingly utilized. This is achieved through the development of new means of production, including laser welding and automated production, both of which offer greater precision at reduced costs. Sustainability encourages the recycling of materials and the use of environmentally friendly steel-making methods to align with global maritime laws. This highlights the industry’s commitment to efficiency, safety, and accountability.

Innovations in Steel Manufacturing

Recent developments in steelmaking are transforming industries that have been heavily reliant on the product. Arguably, one of the most significant breakthroughs has been the development of `green steel’ with reduced carbon emissions. H2 Green Steel and SSAB have led the way in steelmaking using hydrogen instead of coal, reducing CO2 emissions by as much as 95%. This represents a significant step towards achieving global climate goals and is therefore receiving increasing attention as more countries establish net-zero targets.

Another major innovative thrust lies in the greater use of AI and machine learning to organize production more efficiently: AI-based predictive maintenance systems report any equipment faults before they escalate into bigger downtime events, ensuring higher productivity. Increasingly, big data analytics are being utilized to optimize supply chains and streamline processes, ensuring efficient resource allocation throughout manufacturing.

The use of electric arc furnaces has been influencing further in the steelmaking sector: for recycled steel, it is melted using electricity rather than conventional coal-based blast furnaces. Apart from energy efficiency, EAFs are suitable for the circular economy, as they melt scrap steel for reuse. Scrap steel now accounts for approximately 30% of global steelmaking.

Also, nanotechnology is being applied to formulate new steel alloys with enhanced strength, corrosion resistance, and lightweight properties. Significant applications are found in the automotive, aerospace, and construction sectors, where performance and durability are key.

Additive manufacturing innovations, such as steel 3D printing, also bring great opportunities for customization and complex designs. These technologies cut down on material wastes and time of production, thus benefiting economically and environmentally.

These advancements are helping the steel industry enhance the quality and flexibility of its products, ultimately working toward a sustainable and efficient future.

Ecological Considerations in Steel Production

The steel industry faces significant environmental concerns due to its high energy consumption and emissions. Yet, there are a few key steps and practices that can be implemented to soften the environmental impacts. Below are five major nuclear points of consideration and initiatives that drive steel production:

- Energy Efficiency Improvements

Technological advancements have streamlined the operation of steel plants to incorporate energy-efficient processes, such as waste heat recovery systems, which can reduce energy consumption by nearly 30%—thereby minimizing costs and reducing greenhouse gas emissions.

- Carbon Capture and Storage (CCS)

Most steel producers are attempting to mitigate CO2 emissions by adopting carbon capture and storage technologies. Some plants may capture up to 90% of carbon emissions during production.

- Recycling Steel Scrap

By recycling steel scrap, steel producers can significantly reduce the extraction of raw materials and lower energy consumption by about 60%. Steel is one of the most widely recycled materials worldwide, with a recycling rate exceeding 85%.

- Using Renewable Energy

The steel industry is increasingly interested in transitioning to renewable energy sources, such as wind or solar power. This means that, by reduction, the dependence on fossil fuels would be lessened, which would significantly contribute to the industry’s carbon footprint.

- Water Conservation

Steel Manufacturers that prioritize advanced water management systems are recycling water used in production processes, while some plants are achieving water reuse rates of almost 90%. This approach applies less pressure on freshwater resources and reduces wastewater discharge.

These considerations collectively reveal how the steel industry strives to strike a balance between production and environmental conservation.

Future Outlook for Shipbuilding Steel Plates

Shipbuilding steel plates have a promising future ahead, as production systems continue to innovate towards greater efficiency and sustainability. Steel plate manufacturing for the shipbuilding industry must be able to produce thinner, stronger, and environmentally resistant materials, the greatest of these being corrosion resistance. Such developments will enable the shipbuilding industry to meet its growing global demands while adhering to stringent environmental regulations.

References

- Study on Tensile and Fatigue Properties of FH36 Ship Plate Steel at Room and Low Temperatures

This study explores the tensile and fatigue properties of FH36, EH36, and DH36 ship plate steels.

Access the study here - Study on the Material Properties of Aged Steel Exposed to the Arctic Environment

This research investigates the material properties of shipbuilding steels, specifically DH36 and FH36, in Arctic conditions.

View the research here - Effect of Low Temperature on the Fatigue Crack Propagation Behavior of Underwater Manned Vehicle Rudder Materials in Arctic Environments

This paper investigates the behavior of EH36 and other shipbuilding steels under low-temperature conditions.

Read the article here

Frequently Asked Questions (FAQ)

What are the properties of AH36 shipbuilding steel?

AH36 shipbuilding steel is recognized for its high strength, toughness, and weldability, making it an ideal choice for marine applications. It has a minimum yield strength of 255 MPa and is often used in the construction of ship hulls, bulk carriers, and container ships.

How does DH36 steel compare to EH36 steel in shipbuilding?

DH36 steel has slightly lower toughness than EH36 steel but maintains a similar yield strength. Both grades are used in shipbuilding, with EH36 often preferred for applications requiring higher toughness in low-temperature marine environments.

What is the significance of ABS steel in shipbuilding?

ABS steel refers to steel grades certified by the American Bureau of Shipping, ensuring they meet high standards for strength and toughness. These materials are crucial for constructing vessels that can withstand harsh marine conditions.

What are the different plate grades available for shipbuilding?

Plate grades in shipbuilding include AH36, DH36, EH36, and FH36. Each grade offers distinct mechanical properties, with variations in yield strength and toughness, making them suitable for various shipbuilding applications.

What is the rolling process for shipbuilding steel plates?

The rolling process involves shaping steel plates through hot rolling or controlled rolling methods. This process refines the grain structure, enhancing the strength and toughness of the steel, making it ideal for shipbuilding applications.

How does the tensile strength of shipbuilding steel plates affect their use?

Tensile strength is crucial for shipbuilding steel plates as it determines the material’s ability to withstand high stress during service. Higher tensile strength allows for the construction of lighter vessels without compromising structural integrity.

What are the advantages of using FH36 steel plate in shipbuilding?

FH36 steel plate offers higher strength and improved toughness, making it suitable for high-stress applications in the shipbuilding industry. It is particularly beneficial in constructing marine equipment designed for offshore use.

What role do classification societies play in steel plate certification?

Classification societies, such as the American Bureau of Shipping, provide certification for steel plates used in the construction of ships. They ensure that materials meet specific standards for quality, strength, and durability, which is essential for safety in marine environments.

How does the addition of alloying elements affect DH36 and EH36 steels?

The addition of alloying elements like niobium (Nb) can enhance the mechanical properties of DH36 and EH36 steels. This results in better toughness and strength, making these steels more suitable for demanding shipbuilding applications.