The process of anodizing stainless steel involves augmenting the alloy’s corrosion resistance and aesthetic quality. While it is popular for aluminum, exposing stainless steel to anodizing could lead to better corrosion resistance, striking finishes, and increased life for the metallic components. However, why is anodizing important, particularly for industries where durability is key? This article aims to elucidate why anodizing stainless steel is one of the crucial puzzles of material engineering and why it is beneficial by addressing the scientific principles underlying the process. Regardless of whether you are a curious designer, a manufacturer, or someone interested in modern engineering processes, get ready to learn the astonishing aspects of stainless steel that anodizing brings to light.

Can You Anodize Stainless Steel Like Aluminum?

Stainless steel can be anodized, but the procedure differs from aluminum. Unlike aluminum, which undergoes a natural anodizing process that creates a porous oxide layer, stainless steels undergo more complex processes that usually involve electrochemical treatment in strong acid baths. Such treatments yield a thin oxide layer on the surface of the steel, which improves the aesthetic colors, increases the protective wear and corrosion resistance, and affords better endurance under harsh conditions. However, anodizing stainless steel is less common and more expensive than aluminum due to the extensive procedures and specialized gear required, making it most suitable for niche applications where the unique advantages offset the added cost.

Key Details of the Anodizing Process for Stainless Steel

Some factors contribute to obtaining the desired results of anodized stainless steel. They include the following five cores:

- Pre-treatment Cleaning

Stainless steel must be cleaned thoroughly, i.e., all grease and contaminants must be removed before anodizing, in order to achieve a quality adhesion of the oxide layer.

- Electrolytic Solution Composition

Most processes work with sulfuric or phosphoric acid, which are acidic electrolyte solutions. Solutions with differing compositions may considerably alter the durability, color, and thickness of the oxide layer, so they need to be precise.

- Controlled Voltage or Current

The electrochemical process of anodizing stainless steel has some prerequisites. The voltage or current used must be controlled and set at specific levels. If correctly set, a smooth and consistent oxide layer is attained without damaging the steel surface.

- Oxide Layer Thickness

The thickness of the oxide layer can be modified based on the anodized piece’s corrosion resistance and durability requirements. A thicker layer is more robust and corrosion resistant, while a thinner layer is more effective for aesthetic appeal.

- Coloring Options

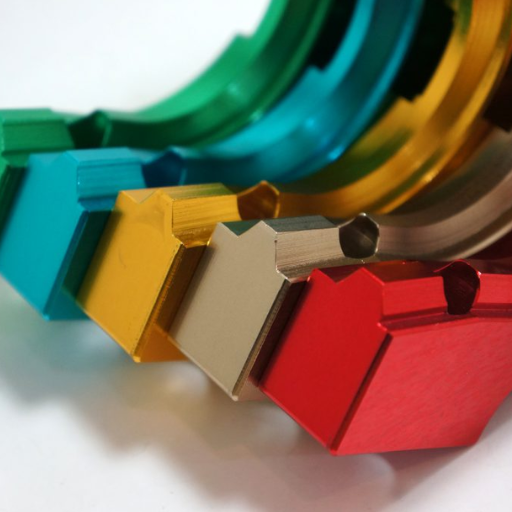

For aesthetic purposes, anodized stainless steel can be treated with dyes or the anodizing process altered to produce a wider range of colors. Such versatility is helpful in design and architecture.

Attention must be paid to both functional and visual details to attain the optimum results in stainless steel anodizing for specialized applications.

The Role of Electrochemical Methods in Anodizing

| Key Point | Details |

|---|---|

| Definition | Electrochemical process forming protective oxide layer. |

| Primary Metals | Aluminum, titanium, magnesium, niobium, tantalum. |

| Key Parameters | Voltage, current density, electrolyte type, temperature, time. |

| Types of Anodizing | Type I (thin), Type II (decorative), Type III (hard coat). |

| Applications | Aerospace, automotive, electronics, cookware, architecture. |

| Benefits | Corrosion resistance, durability, aesthetic enhancement, electrical insulation. |

| Challenges | Limited to specific metals, surface imperfections remain visible. |

| Electrolytes Used | Sulfuric acid, chromic acid, phosphoric acid, oxalic acid. |

| Process Steps | Cleaning, anodizing, dyeing (optional), sealing. |

| Sealing Methods | Hot water, mid-temperature, or cold sealing for durability. |

Challenges of Anodizing Stainless Steel

The processes and techniques for anodizing metals like aluminum differ considerably from those for stainless steel. Stainless steel, due to its corrosion-resistant properties, makes the formation of a sustainable anodic oxide layer very challenging. This is because the chromium present also forms a passive and protective anode over the metal’s surface. VariationThe of stainless steel grades and their finishes can considerably affect the sheath consistency. Taking this one step further, alloys with higher concentrations of molybdenum, such as super duplex stainless steels, are not only harder to anodize, but also increase the corrosion-resistant properties of the alloy, making the anodization process even more difficult ..

Variation of stainless steel grades and their finishes can considerably affect the sheath consistency andTaking this one step further, alloys with higher concentrations of molybdenum, such as super duplex stainless steels, are not only harder to anodize, but also increase the corrosion-resistant properties of the alloy, making the anodization process even more difficult.Variation of stainless steel grades and their finishes can considerably affect the sheath consistency. Taking this one step further, alloys with higher concentrations of molybdenum, such as super duplex stainless steels, are not only harder to anodize, but also increase the corrosion-resistant properties of the alloy, making the anodization process even more difficult.Variation of stainless steel grades and their finishes can considerably affect the sheath consistency. Taking this one step further, alloys with higher concentrations of molybdenum, such as super duplex stainless steels, are not only harder to anodize, but also increase the corrosion-resistant properties of the alloy, making the anodization process even more difficult. The adhesion of the anodized coating to the sheath, yielding a new challenge of uniformity in the anodized layer. Taking this one step further, alloys with higher concentrations of molybdenum such as super duplex stainless steels are not only harder to anodize, but also increase the corrosion resistant properties of the alloy, making the anodization process even more difficult.

In addition, the elevation of the energy costs associated with the anodizing process of stainless steel may pose as a possible restriction. Successful anodization of stainless steel requires the application of different electrolytes as well as further controlled conditions, increasing the amount of time and money spent. New research indicates that the energy used while anodizing stainless steel is almost 30% more than that used with aluminum anodization, highlighting the need for optimization in industrial processes.

Moreover, to take into account social sustainability, strategic actions must be articulated such as the implementation of anodization electrolytes that would mitigate the environmental concerns tied to the electrolyte’s toxicity. The constituent chemicals used to achieve electrolyte and acid solutions for stainless-steel anodization have potentially hazardous environmental effects. The management of these chemicals also incurs costs, which impact profitability..,The management of these chemicals also incurs costs, which impact profitability. The management of these chemicals also incur costs which impacts profitability.

These goals require altering some of the anodizing parameters or employing more sophisticated techniques, such as advanced electrochemical processes The management of these chemicals also incurs costs, which impact profitability.. or traditional anodization enhanced with plasma electrolytic oxidation. Applying such strategies has the potential to resolve these problems, making stainless steel anodizing more practical, cost-efficient, and environmentally friendly.environmental effects

What are the Differences Between Anodized Aluminum vs Stainless Steel?

| Key Point | Anodized Aluminum | Stainless Steel |

|---|---|---|

| Weight | Lightweight, ideal for aircraft | Heavier, suitable for structural applications |

| Corrosion Resistance | High, with anodized layer | High, varies by grade |

| Durability | Moderate, surface can scratch | High, resistant to dents and scratches |

| Heat Conductivity | Excellent, uniform heat distribution | Moderate, often layered with conductive metals |

| Cost | Affordable | More expensive |

| Applications | Aerospace, cookware, electronics | Cookware, medical, architecture |

| Maintenance | Requires careful cleaning | Easy to maintain |

| Nonstick Properties | Often coated, prone to wear | Naturally nonstick with proper seasoning |

| Strength | High strength-to-weight ratio | Superior overall strength |

| Environmental Impact | Lower energy to produce | Higher energy to produce |

Comparing the Corrosion Resistance of Aluminum and Stainless Steel

| Key Point | Aluminum | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Forms protective oxide layer | Chromium layer prevents rust |

| Rust Resistance | Does not rust | Does not rust |

| Saltwater Resistance | Corrodes in saltwater | Excellent resistance |

| Acid/Base Resistance | Poor in acidic/basic environments | Superior resistance |

| Galvanic Corrosion | Corrodes faster when in contact with steel | Slower corrosion in galvanic cells |

| Maintenance | Requires anodizing for better resistance | Low maintenance |

| Marine Applications | Needs marine-grade alloys | Commonly used |

| Durability | Moderate, depends on anodizing | High, long-lasting |

| Environmental Impact | Lightweight, recyclable | Heavier, also recyclable |

| Cost | Generally lower | Higher, but durable |

Differences in Oxide Layer Formation

The differences in the two materials stem from the way the two metals react to the environment. It is important to highlight these points.

- Formation of Oxide Layer

Aluminum exhibits a high reaction with the earth’s atmosphere. Hence, an oxide layer is almost instantly formed due to corrosion.

Stainless steel requires a slow fusion of oxygen and moisture. With these two, the oxide layer will form.

- Composition of the Oxide

The oxide layer formed from aluminum is thin but highly protective since the protective layer of Aluminum (Al) protects it from further corrosion. The additional ions in the air will not affect the integrity of Aluminum.

While the oxide layer on steel sometimes acts as a shielding layer, it is often useless in looking after the underlying steel. (Cr) is corrosively passive, hence protecting the alloying steel.

- Compactness of Oxide Layer

Over time, the oxide layers grown on aluminum will be more effective at protecting the bare metal from rust and corrosion.

Steel oxide layers will be much weaker but will regain thier shape.

- Recovery Rate

In essence, exposed aluminum will regenerate quicker than exposed steel material.

Despite being tagged as a coating, aluminum will regenerate a lot quicker.

- Durability

Although steel is expected to be functional in extreme environments, it will be quite the poser in anything aside from carbon dioxide. Severe acidic or alkaline fluids should cause no stress to the aluminum badge, giving it the advantage.

Stainless steel’s chromium oxide is stable in a broad spectrum of harsh environments, including those with high acidity and salinity.

How Anodized Aluminum and Stainless Steel Affect Surface Properties

| Key Point | Anodized Aluminum | Stainless Steel |

|---|---|---|

| Surface Hardness | Harder than untreated aluminum | Naturally hard, scratch-resistant |

| Corrosion Resistance | Enhanced by an anodizing layer | High due to chromium oxide layer |

| Scratch Resistance | Moderate, depends on anodizing | Excellent, highly durable |

| Heat Conductivity | Excellent, uniform heat distribution | Moderate, retains heat well |

| Weight | Lightweight, ideal for mobility | Heavier, adds stability |

| Surface Finish | Can be dyed, decorative options | Polished or brushed finishes |

| Maintenance | Requires care to protect anodized layer | Low maintenance, easy to clean |

| Durability | Improved with anodizing, but less than steel | Superior, long-lasting |

| Applications | Electronics, cookware, lightweight structures | Medical, architecture, heavy-duty tools |

| Environmental Impact | Recyclable, energy-efficient production | Recyclable, higher energy to produce |

Why is Stainless Steel Difficult to Anodize?

The anodization of stainless steel is difficult due to the material’s inherent properties and the underlying chemistry of the anodizing technique. Whereas aluminum features a porous oxide layer that is conducive to anodization, the chromium oxide skin of stainless steel is markedly thin and stable, resisting further oxidation. This poses challenges in the formation of a thick, porous oxide layer, which is ideal for anodizing.

Moreover, stainless steel does not respond readily to acidic electrolytes, unlike aluminum which can be easily anodized. Stainless steel construction is designed to resist corrosion in practically any acid environment uniformly. Such anodizing electrolytes, however, require precise electrochemical conditions (current density, voltage range, and composition of the anodizing bath), which are more challenging to optimize for stainless steel, often resulting in non-uniform surfaces or layers that are fundamentally compromised.

Specialized conditions for anodizing offer slight improvement, with studies suggesting stainless steel yields thin, fragile coatings while failing standards of durability and adhesion. A case in point is the research published in Surface & Coatings Technology, which cites stainless steel anodizing’s frequent reliance on fluoride-containing electrolytes as highly detrimental to the structural integrity of the stainless steel’s chromium oxide shield. Fluoride compounds, however, raise considerable safety and environmental issues due to their highly corrosive and toxic nature.

Currently, the preferred methods include Physical Vapor Deposition (PVD) or coating stainless steel with oxide layers via thermal or chemical treatments rather than anodizing. These methods offer custom surface properties or additional color options without the restrictions posed by conventional anodizing processes.

The Natural Oxide Film of Stainless Steel

The passive layer, an oxygen-exposed stainless steel, is a composite of chromium oxide and aluminum, called a thin sterile oxide film, created spontaneously. Armor against corrosion and durability stemmed from the alloy’s oxidative risk, making this layer eligible for utility. In my opinion, this amalgam, accompanied by self-healing, was the game changer when augmenting the reliability of ‘stainless’ steel for myriad applications. Oxidative gel in concern needs no additional sedimentary shield or undergoing treatment after preserving its structure. It aptly assists the metal in deferring damaging rust-inducing elements, preserving wellbeing for a prolonged time.

Limitations in Electrochemical Anodization of Steel

One of the primary obstacles in anodic electrochemical steel processes envisioned for stainless steel is ignoring other variables and not achieving the desired unflawed contour with consistent thickness, repeatable leveling, and stable oxide coverage. This reasoning is largely hinged on an intricate mixture, aka composition, and the mechanisms of selective corrosion within a defined scope of possibilities.

Alternatives to Anodizing Stainless Steel

Although anodizing is rarely conducted on stainless steel, many alternatives improve stainless steel’s wear resistance, corrosion resistance, and overall appearance. The following methods are some of the more effective options:

- Electropolishing

Electropolishing is a chemical technique that improves a stainless steel surface by removing a thin material layer to produce a smooth, mirror-like surface. This process beautifies the stainless steel and improves its durability by enhancing its corrosion resistance and decreasing surface roughness. Various studies show that electropolished stainless steels have improved pitting corrosion resistance from 30% to 50% compared to untreated stainless steel.

- PVD Coatings

In PVD, a strong coating is deposited onto stainless steel by vaporizing it in a high-vacuum chamber. PVD is also advantageous because it allows for a variety of colors and finishes, making it useful for both decoration and functionality. PVD-coated steel is highly resistant to abrasion, and the process does not produce any harmful byproducts, proving it is more environmentally friendly.

- Coating of Powder

Applying a layer of color or protection to the surface of stainless steel through an electrostatic process is called powder coating and is regarded as one of the economical options. Modern alloy features also offer enhanced UV powder coatings, which could be matte or glossy. Stainless steel surfaces with a powder coat can withstand salt spray tests for up to a thousand hours, showcasing resiliency in harsh conditions.

- Laser Marking and Texturing

Laser marking and texturing are some of the most precise techniques used to alter stainless steel into intricate shapes. They are also customizable and don’t affect the resistance to corrosion. Laser technology’s most recent advancement is creating very small intricate patterns (micro-texturing) that can be reproduced, which is of particular value for improving the beauty and functionality of architectural and industrial designs.

- Ceramic Coatings

Stainless steel can be protected with ceramic coatings to shield against harsh environmental conditions. Ceramic coatings are hydrophobic, thermally stable, and resistant to scratches. Research shows that stainless steel with a ceramic coat can withstand extreme temperatures of 1,800°F (982°C) for prolonged periods, making them perfect for high-temperature and aerospace purposes.

Comparison of Alternatives

| Method | Key Benefits | Limitations | Best Used For |

|---|---|---|---|

| Electropolishing | Smooth finish, improved corrosion resistance | Limited aesthetic options | Medical, food processing equipment |

| PVD Coatings | Wide color range, high durability | Costs and equipment requirements | Decorative and wear-resistant surfaces |

| Powder Coating | Affordable, UV resistance, versatile appearance | Potential for chipping or cracking over time | Outdoor equipment, furniture |

| Laser Marking/Texturing | Custom finishes, accuracy without affecting steel | Requires specialized equipment | Branding, architectural designs |

| Ceramic Coatings | Heat resistance, superior scratch protection | Application requires precision | High-temperature and industrial uses |

Each alternative offers unique advantages depending on the intended application and desired properties of the stainless steel surface. The choice of method should align with the budget, performance requirements, and environmental conditions of the target use case.stainless steel surface’s intended application and desired properties

What are the Benefits of Anodizing Metal Surfaces?

- Enhanced Durability – Protective anodizing improves the durability of metal by creating a hard protective layer that effectively combats wear, corrosion, and weathering.

- Improved Appearance – Its application allows for various color finishes while maintaining the natural metallic sheen. Anodizing also gives a professional look and a clean finish.

- Low Maintenance – Anodized surfaces can be maintained by simple cleaning without requiring excessive scrubbing, thus reducing the time and effort spent on upkeep.

- Environmental Resistance – Anodizing protects the metal from UV radiation and oxidation, making it suitable for outdoor and industrial use.

- Eco-Friendly Process—The maintenance of a pollution-free environment during the anodizing process enables the use of non-toxic substances and reduces potential environmental impacts.

These benefits support why anodizing is a highly functional solution for aesthetic and usability improvements.

Improving Corrosion Resistance Through Anodization

Anodization provides exceptional improvements in resistance to corrosion, particularly for aluminum. This change is due to the electrochemical reactions which create an oxide film on the surface of the material which prevents attack from water, salt, and air. Research indicates that anodized aluminum does not suffer severe corrosion damage after long exposures to moist marine environments. Additionally, there are reports that anodized aluminum is not corroded in seawater for around 25 years depending on coating quality and other conditions.

The tested coating has proven optimal for moderately corrosive environments and can withstand temperatures up to 95° C, beyond which the protective grade degrades. Other standards, like ISO 7599, establish other parameters, such as a definite 25-micron thickness for anodized coatings if aluminum will be employed in high-corrosion regions. Also, hot water or nickel acetate sealing is an advanced method that increases protective and sustaining capabilities by reducing water absorption by the oxide layer.

For instance, in aviation engineering, anodized metal alloys for components outlast untreated ones regarding ultraviolet energy attack. These materials preserve their protective qualities while being exceptionally light, making them a preferred selection in aerospace engineering.

Because of new sealing processes, water is less absorbed into the oxide layer, which increases durability while maintaining strict quality of production. This helps industries use anodization in a more sustainable way to deal with corrosion while prolonging metal preservation.

Enhancing Hardness and Durability of Metal Surfaces

Numerous processes have been developed to analyze the impact that a specific treatment or technique has on a particular industrial requirement. These processes aim to enhance the hardness and roughness of a given metal surface. At the same time, these methods augment the mechanical properties of the metals while also ensuring their resistance to abrasion, wear, and changes in environment. Some of these methods are highlighted below.

- Anodization

Anodization enhances the hardness of the metal surface by forming a thick oxide layer on the surface via electrochemical oxidation. This process provides better resistance to abrasion and wear and increases the life of a given metal. For instance, anodized aluminum can possess a surface hardness that approaches the levels of Certain steel grades.

- Heat Treatment

Anodization can also be achieved through heating and cooling cycles of metals like steel or titanium. The conscious application of quenching and tempering processes leads to a notable change in the internal composition of the metal’s grades, achieving unprecedentedly sharp hole diameters and uncompromised tensile strength.

- Surface Coating (e.g., PVD Coating)

Titanium nitride PVD coatings are an excellent example of modern coatings that provide extreme suppleness coupled with rigidity. Besides ultra hardness, such coatings also possess a higher proportion of resistance to scratching, wearing, and even oxidation.

- Shot Peening

This is a mechanical treatment in which a stream of high-velocity shot materials is used to compress the surface of metals. This process induces compressive stresses on the material’s surface, improving its resistance to fatigue and structural integrity.

- Laser Surface Treatment

The term Laser Surface Treatment refers to the use of lasers to treat metal surfaces by heating and subsequently rapidly cooling specific areas to improve the surface microstructure. Additionally, laser hardening and melting processes result in increased surface hardness and durability while maintaining precision.

By adopting these practices, industries can greatly increase the functional lifespan of metal components and ensure their reliability in demanding applications.

Achieving a Variety of Colors in Metal Finishes

Metal surfaces can be colored using various techniques, each with a distinct approach to modifying the material’s properties. These methods go beyond beautifying the metal’s surface as they also add value, such as corrosion resistance and protection against wear. The following outlines five techniques that stand out in the creation of color variations on metal surfaces:

- Anodizing

This is an electrochemical technique in which a protective oxide coating is applied to the surface of metals such as aluminum. Blue, red, gold, and black are some of the colors that can be obtained by including dyes in the anodizing process. Anodizing is popular in architectural and electronics works.

- Heat Tinting

Oxide layer formation through controlled heating produces gold, purple, and blue hues. This is common for titanium and stainless steel. This is often used in custom jewelry or artwork.

- Electroplating with Alloys

This involves coating the surface of a part with a thin layer of metal, referred to as electroplating. By using alloy plating solutions, various colors, such as rose gold, chrome, and brass, can be achieved.

- Chemical Patinas

Patinas are widely used when copper and bronze metals are exposed to specific chemical solutions. The reactions emanate beautiful earthy shades of green, brown, or turquoise. This technique is popular in architecture and carving sculptures because of the weathered aesthetic it creates.

- Physical Vapor Deposition (PVD)

One of the most common PVD processes is considered to be one of the most controlled coating processes. It involves the emplacement of thin films of zirconium nitride and various other compounds onto a target metal. The result is the emergence of gold, black, and iridescent color dresses that can be applied both decoratively and industrially.

Each method has distinct benefits, enabling manufacturers and craftsmen to achieve specific visual and functional goals by altering the finishes of the metal.

How Does the Electrochemical Surface Process Work in Anodized Steel?

The anodization process for steel involves an electrochemical surface treatment using an electrolytic cell to form an oxide layer on the steel. This layer increases the steel’s resistance to corrosion and physical damage and improves its overall appearance, making it more visually appealing. The steel is placed in an electrolyte solution, usually either sulfuric or phosphoric acid, and then a current is applied to the solution. The steel is the anode; thus, it forms a controlled and homogenous oxide layer.

Contemporary research suggests that precise control of the voltage and electrolyte materials used can substantially benefit the surface features of the anodized steel. For example, changing the voltage to within the range of 10 to 20 volts, whilst keeping the temperature of the electrolyte solution at around 0°C, can create a more dense and stronger oxide layer. This level of durability makes the anodized steel even more ideal for use in extreme conditions such as industrial and marine environments, where corrosion-resistant materials are crucial.

Additionally, the porous structure of an oxide layer permits dye adsorption, which increases custom color and finish options for anodized steel and improves its aesthetic value. Other studies reveal that anodizing increases the surface hardness of steel by as much as 30%, thus enhancing its longevity and wear resistance. These advancements emphasize the diverse possibilities of the electrochemical surface treatment and the multi-functional and decorative capabilities of anodized steel.

The Science Behind Oxidation and Electrolytic Processes

| Key Point | Details |

|---|---|

| Oxidation Definition | Loss of electrons or gain of oxygen. |

| Reduction Definition | Gain of electrons or loss of oxygen. |

| Electrolysis | Electric current drives non-spontaneous reactions. |

| Electrolytic Cell | Converts electrical energy into chemical energy. |

| Oxidation Site | Occurs at the anode (positive electrode). |

| Reduction Site | Occurs at the cathode (negative electrode). |

| Applications | Metal extraction, electroplating, and water splitting. |

| Faraday’s Law | Relates the charge to the amount of the substance in electrolysis. |

| Key Factors | Voltage, electrode material, and electrolyte composition. |

| Common Products | Hydrogen, oxygen, chlorine, and purified metals. |

Creating a Protective Oxide Layer on Steel Parts

An oxide protective layer formation process involves applying electrolytic treatment to the steel parts, known as anodizing. It employs an electrochemical method of depositing a dense oxide film onto the surface of steel, which greatly improves the steel’s corrosion resistance and durability. Recent research suggests that incorporating chromium or aluminum into the anodizing bath can improve the wear resistance of steel surfaces by up to 45%, making it ideal for industrial purposes where prolonged exposure to moisture or hostile environments is prevalent.

Contemporary development within the area also enables precise control of oxide film thickness from 5 to 25 microns based on the application requirements. Finer layers are more common in electronics and decorative works because of their elegance, while thicker layers are suitable for heavy-duty industrial work. Data from a 2023 metallurgical study indicate that steel components with a protective oxide layer suffer oxidative degradation by 75% over a decade compared to bare steel parts. Moreover, the recent developments in phosphoric acid anodizing have enhanced the adhesion of the anodic coatings, making it more favorable in the aerospace and automotive industries.

These results stem from managing control variables such as electrolyte composition, voltage, temperature, and duration of treatment. For example, the incorporation of real-time monitoring systems allows engineers to optimize these conditions, keeping them consistent while cutting energy use by 20% in massive-scale operations. This highlights the importance of ongoing investigation and application of new technologies to maximize the creation of oxide layers on steel parts.

Applications of Anodized Steel in Aerospace and Other Industries

| Key Point | Details |

|---|---|

| Aerospace Components | Structural parts, landing gear, hydraulic pistons. |

| Corrosion Resistance | Protects against moisture, salt spray, and chemicals. |

| Durability | Enhances wear resistance and surface hardness. |

| Electrical Insulation | Non-conductive layer for safety-critical components. |

| Automotive Industry | Body panels, safety mechanisms, and support structures. |

| Architectural Use | Exterior cladding, roofing, and structural frameworks. |

| Consumer Electronics | Durable casings for smartphones, laptops, and devices. |

| Aesthetic Appeal | Customizable colors and finishes for branding. |

| Eco-Friendly Process | Minimal waste, aligns with sustainability goals. |

| Thermal Insulation | Reduces heat exchange in construction and industrial applications. |

References

- Anodization of medical grade stainless steel for improved corrosion resistance and nanostructure formation targeting biomedical applications

ScienceDirect - Fabrication of thick nanoporous oxide films on stainless steel via DC anodization and subsequent biofunctionalization

ScienceDirect - Evaluation of ion release, cytotoxicity, and platelet adhesion of electrochemical anodized 316 L stainless steel cardiovascular stents

Wiley Online Library

Frequently Asked Questions (FAQ)

Q: What is anodizing, and can stainless steel be anodized?

A: Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of metal parts. Due to its unique properties, stainless steel is typically not anodized. However, a similar process can be applied to anodize stainless steel, though it’s not common or recommended because stainless steel cannot be anodized like aluminum or titanium.

Q: How does anodizing improve the corrosion resistance of stainless steel?

A: Anodizing can improve stainless steel’s corrosion resistance by creating an anodized layer that serves as a barrier against environmental factors that may corrode the steel surface. However, stainless steel inherently has high corrosion resistance due to its chromium content, which forms a passive layer that protects it.

Q: What are the standard process baths used to anodize metals?

A: The process baths used to anodize metals can vary, but they typically involve acidic solutions, such as sulfuric acid for aluminum. Although stainless steel is not typically anodized, processes may include other chemical treatments to modify the surface.

Q: Can the anodizing process be applied to other metals besides stainless steel?

A: Yes, anodizing is commonly applied to aluminum and titanium. Aluminum alloys and titanium are often anodized to enhance their corrosion resistance and aesthetic appearance.

Q: What role does the electrolyte play in the anodizing process?

A: In the anodizing process, the electrolyte allows the flow of electric current between the anode and cathode, facilitating the formation of the anodized layer on the metal surface.

Q: What is the difference between anodizing and plating?

A: Anodizing is an electrochemical process that modifies the metal’s surface by creating an oxide layer, while plating involves coating the metal surface with a different material, such as nickel or gold, to improve appearance or corrosion resistance.

Q: What are the advantages of anodized surfaces?

A: Anodized surfaces offer enhanced corrosion resistance, improved aesthetic appeal, and increased surface hardness. They are also less likely to corrode and can be dyed in various colors.

Q: How does impurity affect the anodizing process?

A: Impurities in the metal or the process baths used to anodize can lead to defects in the anodized layer. These defects can cause irregularities, reduce corrosion resistance, and impact the overall quality of the surface finish.

Q: What is the significance of anodizing titanium in industrial applications?

A: Anodizing titanium enhances its natural corrosion resistance and provides decorative finishes in various colors. This is particularly useful in industries where aesthetic appeal and durability are essential, such as medical devices and aerospace components.