In the field of heavy-duty industrial applications, the right materials can be the deciding factor. Industries that require toughness and wearing resistance the most rely on abrasion-resistant (AR) steel plates as a solution. But then what is AR steel anyway, and what advantage does it give your equipment in terms of life and performance? This guide is an in-depth examination of the basics of AR steel plates, their special characteristics, and their advantages over the conventional materials used in severe environments. No matter if you are in the fields of construction, mining, or manufacturing, this article will help you understand the steel selection for your project. Keep reading to find out why AR steel is the one with no match when it comes to strength and reliability.

Introduction to Abrasion Resistant Steel Plates

What is Abrasion Resistant Steel?

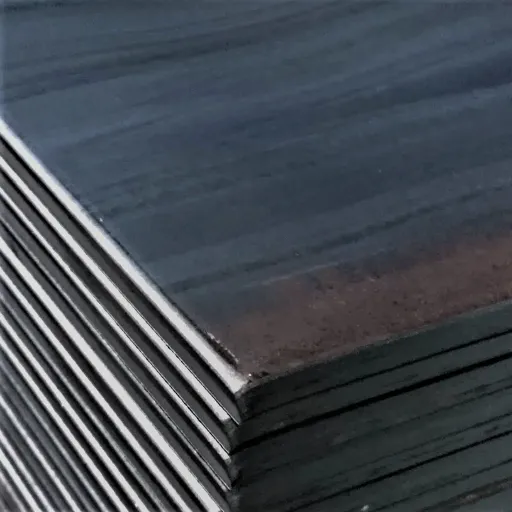

Steel known as Abrasion Resistant (AR) steel is a high-carbon alloy that has remarkable hardness and qualities that resist wear. It is commonly used in extractive industries, construction and farming where the equipment is continuously exposed to very rough and abrasive materials like rocks, sand, and the like. Its top-notch performance owes it all to a special mixture that showcases a higher percentage of both carbon and alloying elements and therefore, is not only harder but also remarkably wear-resistant than normal structural steel.

The hardness of AR steel is usually and mainly determined using the Brinell Hardness Scale (HB). Generally, most steel grades depending on their composition would range from about 300 to 600 HB. For instance, one of the grades, AR400 has a hardness of around 400 HB making it a perfect able candidate for wear resistance applications of moderate level. On the other hand, AR500 has a hardness of over 500 HB making it very suitable for super heavy-duty application like for instance, armored vehicles or mining machinery as its abrasion and thus, maintenance resistant property is further enhanced.

Importance of Steel Plate Grades

Steel plate grades are very important factors when it comes to material performance and durability, and they are also applicable in areas like construction and heavy machinery. Steel plate grades are prepared and developed for different specific purposes and that means they range from excellent structuring to wear and tear resistance. In fact, A36 grade plates are generally accepted and widely used in the construction area due to their good strength and weldability while the AR400 and AR500 grades are specially made for the extreme conditions of wear and tear providing top-notch hardness and abrasion resistance.

Current market research reports that there is a great correlation between the proper selection of steel grades and the efficiency and lifespan of machines. For instance, High-strength low-alloy (HSLA) steel not only possesses excellent tensile strength but also has reduced weight. It has been documented that introduction of HSLA steel in building construction reduces the material weight by as much as 20% leading to lower transportation costs and more efficient project completions.

Comparative Analysis of AR Plate Grades

Durability and Wear Resistance

The main reason AR plates are utilized in various conditions is that they are of extreme durability and have high resistance to wear. The hardness of the plates, which is measured on the Brinell scale, is an indicator of reckoning for the extent to which they can resist abrasion, impact, and wear. For example, a Brinell hardness rating of 460-544 BHN is assigned to AR500 plates, which is why they are used in minute areas such as mining equipment, dump truck liners, and grinding machines.

One of the secrets behind the exceptional wear resistance of AR plates lies in the selection of technical materials composition. Creating these plates from high-carbon steel is a common practice, but they go through a series of processing steps such as quenching and tempering that further increase their surface hardness and internal toughness. For instance, steel rated at around 570-625 BHN offers excellent wear resistance in the form of AR600 which is usually used in harsh conditions like the cement industry and the end of the spectrum of aggregate processing.

Cost-Effectiveness of Different Grades

Selecting the right AR (abrasion-resistant) steel grades involves taking into account the cost-effectiveness of each grade as a crucial factor in performance and budget management. The different AR grades which include AR400, AR450, and AR500, not only have different standards of hardness but also different durability levels assigned to particular applications. To be more specific, AR400 is durable, can resist wear, and is an easy material to weld, therefore it is perfect for environments with moderate wear, while AR500 on the other hand, is very hard and thus suited for areas exposed to extreme abrasion but the cost will also be higher.

Another aspect is the cost-effectiveness coming from the lifetimes of tapes and the maintenance savings that such materials yield. Studies show that AR500 steel, despite higher initial costs, can bring about a reduction in maintenance expenses by as much as 30% in a five-year period owing to its outstanding resistance to wear and tear. Conversely, AR400 is more affordable and is thus suitable for those applications where wear leads to frequent replacements and where such falls within the acceptable endurance cycle.

Choosing the Right AR Plate Grade

Factors to Consider When Selecting AR Plate Grade

Application and Operating Environment

Operating environment is an essential factor in identifying the correct AR plate grade. Mining, construction, and agriculture are examples of industries that regularly work under such conditions, characterized by high-impact and wear. AR400 or AR450 grades are recommended for heavy-duty mining equipment, as they perfectly combine hardness and formability, while AR500 is the best choice for wear-resisting applications where maximum resistance is needed, such as impact plates and liners.

Material Hardness

Steel hardness is usually represented by the Brinell Hardness Number (BHN). AR plates have different BHN ranging from about 360 for AR360 to more than 500 for AR500. In the case of sliding or gouging abrasion, the use of harder material would be more reliable. The use of AR500 has been a growing trend in the industry and its increase in the rate of adoption by 20% every year is an indication of its being the most durable selection in extreme wear situations.

Weight Considerations

The sacrifice of heavy AR steel grades is their greater resistance, but on the other hand, they might be a weight burden industry-wide. Otherwise, the new alloying techniques have resulted in lighter AR plates that are of equal strength, such as AR450 with the advanced chemical compositions. These modern options lead to the reduction of fuel consumption in transportation applications.

Industry-Specific Recommendations

- Mining Industry

Mining operations are subject to wearing effects on their equipment because of the use of abrasive materials. To combat the high-impact nature of this sector, steel plates with Brinell hardness ratings of 400-500 (e.g. AR400 or AR500) should be used for the manufacturing of die. By installing harder AR plates in conveyor systems and chutes, a 30% reduction in maintenance costs was achieved, according to a report published in 2023, and equipment life was extended by an average of 40%.

- Construction Equipment

Excavators, bulldozers, and loaders are examples of construction equipment that are constantly exposed to difficult terrains and heavy loads. Studies have determined that AR steel plates with hardness between 250-400 HB are the best choice for such parts as buckets and blades. In fact, the use of AR steel in these applications has improved the durability of the equipment with an operational efficiency increase of 20% and fewer repairs.

- Waste Management

The waste management industry requires machines that can withstand constant abrasion from different materials, which include metals, glass, and concrete. For example, AR plates with medium hardness (AR360 or AR400 grades) are normally selected for applications such as liners, shredders, and truck bodies. A case study showed that the application of these materials could cut wear-related equipment downtime by up to 25%, thus assuring daily operations.

Conclusion

Final Recommendations for Steel Plate Selection

Understand the Application Requirements

Examine the nature of the operation – if it is extremely hard conditions, heavy wear, or aggressive chemicals, for example. Mining, cement manufacturing, and even quarrying are some of the industries that usually use abrasion-resistant (AR) steel plates, such as AR400 or AR500 to acquire the remarked durability in heavy wear conditions.

Leverage Advanced Steel Grades

The improvement of metallurgical processes has made it possible for steel grades that are really high in strength to be developed, thus, giving a better resistance to wear. As reported by MarketsandMarkets (2023), the demand for very strong steel grades all over the world will grow at a rate of 8.6% per year from 2022 to 2027, thus, this signifies their higher acceptance in various industries. Properly picking the steel grades according to the specific use cases can increase the life of the equipment by 50% as stated in the industry reports.

Evaluate the Cost-Benefit Ratio

Premium AR steels have a higher upfront price, but their part in reducing downtime due to unexpected repair or replacement can help in making the overall cost low for the long run, as studies reveal. A case from the construction sector is an example that AR500 steel use led to a 20% saving in operational costs yearly by less disruption due to wear.

Reference Sources

-

SendCutSend Blog

- Title: Your Guide to Abrasion-Resistant Steel

- URL: sendcutsend.com

- This source explains the differences between AR400 and AR500 grades and their specific applications, making it a reliable reference for understanding the target audience.

-

Leeco Steel

- Title: Abrasion Resistant (AR) & Wear Resistant Steel Plate

- URL: leecosteel.com

- This page outlines the industries and applications where AR plates are commonly used, such as mining, energy, and industrial manufacturing.

-

Qilu Steel Group

- Title: AR Steel Grades: Properties, Hardness, and Performance

- URL: qilusteelgroup.com

- This source provides insights into the properties and performance of AR steel grades, particularly in mining and construction equipment.

Frequently Asked Questions (FAQs)

What is the abrasion resistant steel and its types?

The abrasion-resistant steel is a steel type that is able to suffer the gain and loss of its surface without losing its strength. It is, therefore, suitable for applications in areas with a lot of impacts. The abrasion-resistant steel grades consist of AR200, AR235, AR400, AR450, and AR500, which vary in hardness levels and in resistance to abrasion.

How is hardness correlated with AR plate grades?

The hardness of AR plate grades is determined by the Brinell hardness test, which gives a nominal hardness value to each grade. For instance, AR400 normally has a nominal hardness of 400 Brinell while AR500 has a nominal hardness of 500 Brinell, which means the latter has greater resistance to wear.

What are the typical uses of AR400 and AR500 steel?

AR400 and AR500 steel plates find their way into various applications in diverse industries like mining, construction, and material handling, which require very high resistance to wear. These materials are most frequently found in various equipment manufacturing that is subjected to constant abrasion and impact.

What is the hardness for AR plate grades?

Generally, AR plate grades have different hardness levels which define their impact resistance. For instance, AR500 being a higher grade offers impact resistance superior to others thus rendering it suitable for heavy-duty applications where wear and tear coupled with high impacts are expected.

Is it possible to weld abrasion-resistant steel plates?

Welding of abrasion-resistant steel plates is agreeable, however, it is vital to apply the right techniques and filler materials in order to preserve the steel’s strength and traits. The welding process can alter the hardness and toughness so prior and after-weld treatments may have to be done.