Steel bridges are testaments to modern man’s imagination and the miracle of modern engineering! They seamlessly blend strength, durability, and design into an iconic structure, making it a modern pose for wonder. Bridges serve as a connector of people, places, and opportunities. Steel has been used for over a century, offering unparalleled Truss and Suspension bridges and unmatched versatility and reliability. Steel is at the forefront of bridge construction. This article dives into the astounding universe of steel bridges, investigating the innovations forming their construction, the problems civil engineers confront daily, and the lessons learned from these remarkable structures. Suppose you are an enthusiast of engineering, a visionary design professional, or a curious soul who wants to know how modern steel bridges have transformed transportation for people. In that case, it will unveil astounding inventions coupled with imagination beyond comprehension, observing the incredible insight into the challenges these exotic structures easily overcome effortlessly, which we call extraordinary structural masterpieces.

What Makes a Steel Bridge Stand Out?

Steel bridges stand alone for their remarkable strength, flexibility, durability, and resistance. Steel possesses the best features a material can offer, whether supporting massive loads or resisting intense weather conditions. Steel never fails to impress, making it an ideal material for long spans and complex designs. Architectural styles and versatility further complement steel’s everlasting appeal. Lastly, steel bridges have gained an efficient reputation as they become effortless tasks when it comes to construction, and with proper maintenance in the long run, they’re cost-effective.

Key Components of Bridge Steel

Every bridge design requires specific bridge steel properties to guarantee its strength, durability, and suitability to a particular design. The most important properties and components of bridge steel are:

- Strength and Durability

Modern bridge steel is developed to endure high stress and heavy loads. The commonly used ASTM A709 grade is known for its outstanding tensile strength and structural integrity. For instance, Scan A709 Grade 50 steel has a minimum yield strength of 50000 psi, making it resilient to static and dynamic loads.

- Corrosion resistance

Weathering steels like ASTM A588 and ‘COR-TEN’ often protect bridges in harsh environments because they resist corrosion. This type of steel is very effective for maintenance-free weathering because it forms a protective rust layer that reduces expensive maintenance. It is particularly effective in areas with frequent rainfall and places with salty air, like coastal regions.

- Weldability and machinability

Bridge steel must make fabrication and assembly as easy as possible. Structural steel grades are designed to allow efficient welds and high-speed fabrication. Because of their sheer strength and excellent weldability, high-performance steels (HPS) are most often used. This choice is better because it reduces construction costs with strong labor costs.

- Resistance to Fatigue

Bridges undergo loading and unloading cycles as vehicles and pedestrians pass over them. Selecting fatigue-resistant steel is essential for long-term safety. Research indicates that the fatigue life of steel is primarily influenced by quality and the layout of structural connections, thereby requiring thoughtful design.

- Sustainability and Recyclability

Steel can be 100 percent recycled as a recyclable material, lowering the environmental impact of the bridge’s construction. Reports indicate that structural steel is recycled more than 90 percent, lowering carbon pollution and strengthening industry efforts to support environmental sustainability.

- Advanced Coating Technologies

Performance steel structures are often enhanced using advanced coatings aimed at improving performance. Protective coatings like galvanization and epoxy-based paints help limit exposure to wear, increasing the bridge structure’s life.

- Earthquake Resistance

Steel used in bridges is designed to withstand seismic energy and still bend, not break. These high-performance steel grades also have to be tailored to particular regional demands for seismic protection, which guarantees the fortification of bridges in areas prone to earthquakes.

With all the highlighted remarkable properties and technologies, engineers and architects continue to opt for bridge steel because it is strong, highly adaptable, sustainable, and complies with the rigorous requirements of modern infrastructure projects.

The Role of Structural Steel in Bridge Design

| Key Point | Description |

|---|---|

| Strength | High load-bearing capacity. |

| Durability | Resistant to weather and corrosion. |

| Flexibility | Adapts to various design requirements. |

| Lightweight | Reduces overall bridge weight. |

| Cost-Effectiveness | Economical for long-term use. |

| Ease of Construction | Simplifies and speeds up assembly. |

| Sustainability | Recyclable and eco-friendly material. |

| Aesthetic Versatility | Enables innovative and appealing designs. |

| Maintenance | Requires periodic inspection and care. |

| Safety | Ensures structural integrity under stress. |

Understanding Corrosion and Maintenance of Steel Bridges

| Key Point | Description |

|---|---|

| Causes of Corrosion | Moisture, salt, oxygen exposure. |

| Inspection Frequency | Regular checks to detect early damage. |

| Protective Coatings | Paints and galvanization prevent corrosion. |

| Cathodic Protection | Electrochemical method to reduce corrosion. |

| Drainage Systems | Prevent water accumulation on surfaces. |

| Material Selection | Use corrosion-resistant steel alloys. |

| Cleaning | Remove debris and contaminants regularly. |

| Structural Repairs | Address damage promptly to avoid escalation. |

| Environmental Factors | Consider climate and pollution levels. |

| Lifecycle Costing | Plan for long-term maintenance expenses. |

How is a Steel Bridge Fabricated?

The fabrication of a steel bridge is a meticulous process that includes the following steps to maintain strength, resistance to wear, and accuracy:

- Design and Planning – An engineering team prepares designs for the steel bridge concrete detailing, including dimensions, materials to be used, and other constituent processes for effective standards and requirements.

- Material Preparation—The engineering team has predetermined the steel bridge, so high-grade steel is gathered, shaped, and cut into appropriate parts. For this purpose, oxyfuel, laser, or even plasma cutting may be implemented.

- Component Assembly – Now, each larger bridge component is further subdivided into smaller constituents. As the name implies, surface treatment components are designed to emphasize surface aspects for precision and alignment, and smaller steel blocks are welded and riveted to create larger blocks.

- Surface Treatment – Subsequent corrosion is prevented by cleaning the steel surfaces and applying paint or galvanization and other specific coatings.

- Quality inspection: Design requirements give cuts. Each verification procedure examines noncompliance errors and variations in set measurements in detail.

- Transportation and Installation—In the end, the only thing remaining to be done is to shift the fabricated bridge parts to the site for assembly, followed by the erection of the ready component.

These steps allow steel bridges to be built in safe, efficient, and environmentally and structurally enduring manners.

Steps in Fabrication of Steel Bridges

Steel bridges undergo fabrication with meticulous precision, advanced technology, and industry-level quality checks. Following is a comprehensive snapshot of the processes that outline the steps of fabrication as far as details and data from the industry practices is concerned.

- Design and Engineering Planning

The derivation of the bridge design and fabrication starts with a detailed discussion of its parts. CAD tools such as AutoCAD and STAAD.Pro enables engineers to model the bridge’s components while factoring in the environment, live load, dead load, stress limits, and more. Studies show that CAD reduces planning time by 30% across various design projects and enhances accuracy.

- Material Selection and Procurement

Fabricating a bridge structure begins with acquiring high-quality steel. Based on the bridge’s structural attributes, grade A36, A572, or A588 (Corten Steel) weathering steel may be chosen. Higher-grade steel is more suitable for long spans or heavily loaded bridges due to its enhanced load-carrying capacity. Structural steel is gaining recognition as one of the most universally used components, as demand is growing by 3.5% year on year.

- Cutting and Shaping

Different sections and steel plates are cut into exact shapes using precise CNC plasma cutting machines or waterjet cutters. Laser cutting is widely accepted owing to the reduced waste, with precision tolerances reaching an astonishing ±0.1mm. The use of advanced technology not only improves accuracy but also improves efficiency and reduces waste by an additional 15% in comparison to manual work.

- Assembly and Welding

Steel components are assembled into substructures that become the bridge’s beams or panels. Welding is critical in this step, using submerged arc welding (SAW) or metal inert gas (MIG) to ensure adequate strength. Automation and robotics play a crucial role, delivering up to 40% improvement in productivity and decreased welding defects with robotic welding.

- Surface Treatment and Corrosion Protection

Steel components undergo surface cleansing by abrasive blasting to remove foreign materials. After this, polishes, epoxies, and even polyurethane topcoats are used as anti-corrosion layers. On construction sites located in a marine or coastal context, galvanization is preferred for stronger rust protection, which increases the bridge’s life by 25-30 years.

- Inspection and Quality Control

The inspection process checks the company’s compliance with industry standards, particularly ASTM, AASHTO, or EN 1090. Micro-errors or micro-cracks are detected using superlatively accepted Non-destructive testing (NDT), ultrasonic testing, and radiographic inspection. Digital check-up tools have advanced recently, increasing the accuracy of the quality assessments by almost 20%, enabling safety requirements to be achieved far more easily.

- Transportation and Installation

The construction site is accessed by modular transporters or uniquely designed vehicles, which also transport the completed steel parts or components. The crane lifts the components off-site and assembles them into the final construction. Novel erection procedures for major steam projects, such as incremental launching or floating, are used and have been proven to reduce construction pace by up to 40%.

Steel bridge fabrication constantly evolves, attributed to the combination of traditional expertise and modern technology. These thorough and data-driven processes allow unparalleled steel bridges to endure enormous forces and severe environmental conditions and prevail for decades.

Importance of Welding in Bridge Construction

Welding is vital during bridge construction because it affixes the integrity and strength of the steel parts. Welding the steel parts best takes care of the immense loads and stresses the bridge must handle physically and mechanically. Adequate welds will also protect the structure from corrosion, temperature changes, and general wear and tear, thereby extending the structure’s service life. For me, modern bridge construction focuses on the safety and reliability of welding, and thus, high-quality practices are a must.

Challenges in On-Site Installation

A set schedule comes with deadlines and peak productivity settings. During the installation phase, the weather, site condition models, and the components’ alignment precision all add to the uncontrolled parameters that must be dealt with.

What Are the Types of Bridges Built Using Steel?

Steel’s durability and versatility make it a great candidate for constructing different types of bridges. The significant types of steel bridges are:

- Beam Bridges—The simplest forms are comprised of horizontal beams. Steel increases their lifespans and load-bearing capabilities.

- Arch Bridges – Distinctive for their arch design, these bridges use steel for arch arms because steel can handle large compressive loads while remaining flexible.

- Suspension Bridges—These bridges are built using steel and cables, allowing them to span a huge distance without support.

- Cable-Stayed Bridges – These bridges are like suspension bridges, but the cables are secured to the towers. Steel prevents unhealthy movement and maintains good weight distribution.

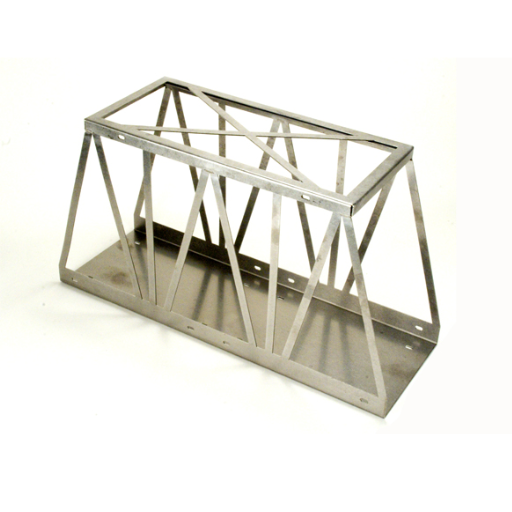

- Truss Bridges – Strong and lightweight, these bridges span distances while using triangular steel frames.

The different types of bridges fulfill unique design and engineering standards, which steel meets excellently.

Exploring Girder Bridges

| Key Point | Description |

|---|---|

| Definition | A bridge is supported by girders or beams. |

| Types | Plate girders and box girders. |

| Material | Commonly steel or concrete. |

| Design Simplicity | Straightforward and cost-effective. |

| Span Range | Suitable for medium to long spans. |

| Load Distribution | Efficiently transfers loads to supports. |

| Construction Speed | Prefabrication enables faster assembly. |

| Maintenance | Requires regular inspection and upkeep. |

| Applications | Highways, railways, and pedestrian bridges. |

| Limitations | Span and design flexibility constraints. |

Understanding Truss Bridges

| Key Point | Description |

|---|---|

| Definition | Bridge with triangular structural elements. |

| Materials | Wood, iron, steel, or combinations. |

| Types | Pratt, Warren, Parker, Camelback, Pennsylvania. |

| Strength | High load-bearing capacity. |

| Span Flexibility | Suitable for short and long spans. |

| Cost Efficiency | Minimal material waste, economical design. |

| Applications | Railroads, highways, and military operations. |

| Maintenance | Requires regular inspection and upkeep. |

| Design Complexity | Precise calculations and execution are needed. |

| Limitations | Heavyweight, space-consuming, and material-sensitive. |

Characteristics of Cable-Stayed Bridges

Cable-stayed bridges are magnificent modern constructions and engineering marvels that blend strength with aesthetics. The primary features of cable-stayed bridges are the following:

- Maximized Material Efficiency

Compared to other bridge types, these bridges are economical for longer spans because the steel towers directly support the road. The suspended deck is supported by steel cables, reducing the materials needed.

- Suitable For Long Spans

Cable-stayed bridges are effective for medium to long spans, mostly between 500 and 2,000 meters. They are suitable for crossing large geographic features such as rivers and bays.

- Eyecatching Design

Cable-stayed bridges serve as major landmarks and add to the architectural beauty of the area because they are extremely eye-catching. The unique patterns made with towers and cables, along with the overall shape of the bridge, make it stand out in the area.

- Structural Versatility

With various design options, such as radial, harp, or fan-shaped cable layouts, vertical or horizontal members, and varying tower lengths, cable-stayed bridges can be tailored to fit specific project requirements.

- Lower Construction Cost & Time

Due to their uncomplicated building procedures and optimal material utilization, cable-stayed bridges can be constructed quickly and cheaply than suspension bridges for spans of the same length.

These attributes make cable-stayed bridges among the most modern infrastructure projects sought after by every country on the planet.

How Does Prefabrication Benefit Bridge Construction?

The benefits of prefabrication in bridge construction are remarkably unparalleled:

- Time Savings: Prefabricated parts are constructed in another area, allowing quicker on-site assembly.

- Cost Efficiency: Prefabricated structures built outside construction sites limit labor costs and slow down spending that would otherwise expedite the project’s completion.

- Quality Improvements: Durability and quality assurance are easier to manage in a controlled environment where the components are manufactured.

- Improved Environmental Impact: Construction site workers are kept to a minimum, reducing noise levels, dust, and even disruption of the surrounding areas.

Due to these benefits, modern bridges are increasingly being built using prefabrication technology.

Advantages of Prefabricated Steel Bridges

| Key Point | Description |

|---|---|

| Quick Assembly | Reduces construction time significantly. |

| Cost-Effective | Saves on labor and material costs. |

| Weather Resilience | Less affected by weather delays. |

| Eco-Friendly | Made from recyclable materials. |

| Lightweight Design | Reduces load on substructures. |

| High Durability | Long-lasting with minimal maintenance. |

| Safety | Safer construction environment for workers. |

| Versatility | Suitable for various terrains and designs. |

| Traffic Disruption | Minimizes impact on traffic flow. |

| Emergency Use | Ideal for quick deployment in crises. |

Innovative Modular Bridge Solutions

Modular bridges are an innovative advancement in the construction industry due to the use of prefabricated parts and engineering techniques. This approach allows bridges to be built in a shorter time frame, incur less cost, and be more flexible to different location conditions.

One of the most effective examples of modular bridges is the use of Accelerated Bridge Construction (ABC) methods. The Federal Highway Administration (FHWA) reports that ABC methods can reduce construction time by 50-80% compared to conventional methods. Off-site assembly of large bridge sections, followed by rapid installation on-site, drives this result.

In addition to this, high-strength materials, such as advanced steel alloys and ultra-high-performance concrete (UHPC), are incorporated into modern modular bridges. These not only increase the structural integrity, load bearing, and life of the structure but also improve the overall durability of the building. It is proven that bridges built with UHPC can maintain service life for over a century while significantly lowering maintenance costs.

Modular pedestrian bridges are another impressive example installed in urban areas with high pedestrian traffic, where congestion can be avoided. These off-site computerized units enable city planners to reduce construction road closures by days or weeks, improving public perception and reducing economic impact due to halted vehicular movement.

Recent project data also shows an increasing global acceptance of modular bridge solutions. China, for instance, has seen an annual 15% growth in the construction of modular bridges to meet the country’s expanding infrastructural requirements and achieve sustainable construction objectives. At the same time, European nations such as Sweden are adopting modular bridge designs to meet the tighter ecological goals, using upcycled steel and cutting emissions by up to 25% during construction.

With new technologies such as BIM (Building Information Modelling) and automated fabrication systems, the coming decades will likely see the rightfully accelerated development of modular bridge solutions that promise smarter, speedier, and greener infrastructure evolution.

What Are the Applications of Steel Bridges?

Steel bridges have applications in various domains because of their unrivaled strength, durability, and versatility. They are heavily relied on in highway and railway systems as they can support and carry heavy traffic volumes and facilitate smooth movement. Steel bridges, such as pedestrian bridges and overbridges, are also crucial to the urban superstructure. Furthermore, they apply to factory and power plant access structures and superlative suspension and arch bridges. Steel’s various qualities allow it to be used in extreme and demanding environmental and operational conditions.

Use of Steel in Railway Bridges

Steel holds remarkable importance in constructing railway bridges because of its immense adaptability, durability, and strength. The exceptional qualities of steel enable railway bridges to withstand and endure the massive load and vibrations caused by trains for a long time without losing structural integrity. Here are some notable features and advantages of using steel in railway bridges:

- Elevated Strength-to-Weight Ratio

Steel has an exceptional strength-to-weight ratio, which is beneficial for use in long-span railway bridges as it will not compromise the structure’s weight capacity.

- Durability and Longevity

With appropriate maintenance, steel bridges can withstand over a century of service life and resist moisture, heat, and cold elements.

- Efficiency in Prefabrication and Assembly

Steel constituents can be prefabricated in workshops, so all the pieces can be easily transported to the construction site and swiftly assembled, greatly shortening the construction period.

- Flexibility to Modern Design Needs

Steel is highly adaptable and easily molded into intricate patterns that suit different spans, geometries, and other architectural features.

- Sustainability

Steel can be regarded as socially responsible in the context of railway bridge construction, as it can be reused without losing its quality, thus reducing waste and contributing to the circular economy.

These features reinforce steel’s profound value in safeguarding railway infrastructure’s safety, efficiency, and civil longevity.

Building Pedestrian and Vehicular Bridges

With the construction of pedestrian and vehicular bridges, my first choice is steel due to its strength, versatility, and eco-friendliness. Steel’s adaptability to various designs and load-bearing requirements ensures the bridge’s functional and aesthetic needs are met. Moreover, steel is fully recyclable, which helps reduce construction waste, aligning with eco-friendly practices and sustainable development targets.

Adapting to Long-Span Bridges Needs

Crossing wide rivers, vast valleys, or busy waterways with long-span bridges is a hallmark of engineering, but not without immense challenges since intermediate supports cannot be used. These structures must be balanced with innovative designs, impressive aesthetics, functionality, and durability. Long-span bridges are typically made of steel because they have the highest tensile strength, are highly flexible, and can withstand dynamic loads such as traffic, wind, and seismic activity.

A striking illustration would be the Akashi Kaikyō Bridge in Japan, which has the world’s longest suspension bridge and a central span of 1,991 meters (6,532 feet). High-strength steel cables coupled with an aerodynamic design were installed to guarantee equilibrium against strong winds, typhoons, and even earthquakes to attain this remarkable bridge span. In the same way, the French cable-stayed bridge Millau Viaduct utilizes chic steel composites to maintain structural efficacy while allowing 342-meter-long spans between piers.

As per the latest research, the design and construction processes of long-span bridges are more refined owing to improvements in material science and computer simulations. The use of lightweight, high-performance steel alloy decked bridges enables even greater reductions in the overall weight of the bridge while retaining the structural soundness, and computational modeling makes it possible for engineers to anticipate the stress factors and optimize the resource consumption. Moreover, many new bridges are constructed with IoT technology integrated monitoring systems that provide instantaneous evaluations of stress, load, and environmental aspects to ensure safety and performance over a prolonged period.

As with these monitoring advancements, sustainable techniques such as the recycling of manufactured steel parts and energy consumption during production processes also make significant contributions, highlighting the adaptability of modern bridges to cope with ever-increasing demands of infrastructure expansion while tending to environmental responsibilities. Long span bridges serve the profound purpose of linking remote regions, however, they also act as masterpieces showcasing the phenomenon of human intellect and the never-ending endeavor of engineers to achieve outstanding milestones.

References

- American Society of Civil Engineers (ASCE): Steel Bridge – ASCE

This site provides insights into steel bridge design and construction, adhering to real-world engineering guidelines. - Iowa State University – Institute for Transportation: Evaluation of the Performance of A1010 Bridge Steel

A detailed academic paper evaluating the structural and fatigue performance of ASTM A1010 steel for bridge applications. - Federal Highway Administration (FHWA): Development of A Bridge Steel Database

This resource discusses the development of a database for steel bridges, including their performance and usage statistics.

Frequently Asked Questions (FAQ)

Q: What are the main structural components of steel bridges?

A: Steel bridges’ main structural components include beams, girders, decks, and plate girders. These elements work together to support the bridge’s live load and weight, ensuring stability and strength.

Q: How do plate girder bridges differ from other steel bridges?

A: Plate girder bridges utilize large steel plates for constructing the girders, making them suitable for longer spans and heavier loads. This design allows for flexibility in length and height, catering to various highway bridge needs.

Q: What are the advantages of using steel in bridge construction?

A: Steel bridges offer a high strength-to-weight ratio, durability, and cost-effectiveness. They can withhold significant live loads and environmental stresses, making them a reliable choice for modern infrastructure.

Q: How does the design and construction of a steel bridge ensure its longevity?

A: The design and construction of a steel bridge involve carefully selecting materials, such as high-strength steel products, and meticulously planning the structural system. Reinforcement and protective coatings are applied to prevent corrosion and extend the bridge’s lifespan.

Q: What role does the deck play in a steel bridge?

A: The deck of a steel bridge serves as the roadway or surface that vehicles and pedestrians use. It distributes loads to the steel girders and supports the overall structural system of the bridge.

Q: What innovations are being introduced in steel bridge solutions?

A: Innovations in steel bridge solutions include using orthotropic and composite decks, advanced structural steel types, and enhanced fabrication techniques. These advances aim to improve durability, ease of erection, and overall performance.

Q: How do steel structures accommodate different lengths and types of crossings?

A: Steel structures are versatile and can be designed to accommodate various lengths and types of crossings. From short-span to long-span highway bridges, steel’s flexibility allows for customized solutions that meet specific engineering and environmental requirements.

Q: What is the role of the National Steel Bridge Alliance in steel bridge construction?

A: The National Steel Bridge Alliance plays a crucial role in promoting the use of steel in bridge construction by providing resources, best practices, and technical support to engineers and builders to ensure the effective design and implementation of steel bridges.

Q: What are the benefits of using a steel plate girder in bridge construction?

A: Steel plate girders offer enhanced strength and flexibility, which are ideal for longer spans and heavier loads. They also allow for precise engineering and efficient material use, contributing to the bridge’s cost-effectiveness and durability.

Q: How is the live load managed in steel bridge designs?

A: Steel bridge designs manage the live load by strategically placing steel beams and girders, ensuring that weight is evenly distributed across the structural components. This approach maximizes the bridge’s capacity to efficiently handle dynamic and static loads.