Industries need to select the best raw materials to have the highest quality product that will be durable enough to withstand harsh environmental conditions while still producing goods. The HASTELLOY® C276™ round bars are the most suitable material for this type of industry. The advantages of the performance alloy include extremely good corrosion resistance, high strength, and extreme versatility, and are therefore used in such industries as marine engineering and pollution control, as well as chemical processing plants. This article will outline how and why China has become the leading manufacturer of HASTELLOY® C276™, as well as give an overview of the properties and benefits of sourcing products manufactured in China that are made from HASTELLOY® C276™. Keep reading as we reveal why HASTELLOY® C276™ is the most preferred alloy to use in demanding applications in many different industries.

Introduction to Hastelloy C276

What is Hastelloy C276?

Hastelloy C276 is a nickel-molybdenum-chromium alloy of unparalleled versatility due to its ability to withstand an extremely broad range of harsh chemical conditions. The unique capability of Hastelloy C276 to tolerate both oxidizing and reducing environments is one of the main reasons it is often used in situations where corrosion resistance is of paramount importance. The high resistance of Hastelloy C276 comes from its combination of metals; typically, Hastelloy C276 contains about 57% nickel, 15-17% molybdenum, 14.5-16.5% chromium, and trace amounts of iron, cobalt, and tungsten.

One of the principal features of Hastelloy C276 is its ability to resist pitting, stress corrosion cracking, and crevice corrosion even when exposed to very aggressive substances, such as oxidizing agents or corrosive hot media. This characteristic makes Hastelloy C276 particularly well suited for a wide variety of industrial applications, including chemical processing, environmental control, pulp and paper, and marine engineering. Specific examples of applications include flue gas scrubbers, chemical reactors, heat exchangers, and pipeline construction.

In addition to its superior chemical resistance, Hastelloy C276 is equally famous for its excellent mechanical characteristics, including a tensile strength of approximately 115 ksi (793 MPa) and the ability to be successfully welded. Because of the very high temperature capability of Hastelloy C276 (for some applications, over 1000°F/538°C), it is an important material for many critical industrial applications.

Significance of UNS N10276

Hastelloy C276, also known as UNS N10276, is one of the most corrosion-resistant, versatile, and widely used nickel-molybdenum-chromium alloys. Especially in dealing with very aggressive chemicals, Hastelloy C276 exhibits remarkable resistance to strong oxidizing and reducing agents and to many complex commercial chemical mixtures. Because of its outstanding ability to resist localized forms of corrosion such as pitting and crevice corrosion, this alloy is used as a preferred material in applications where reliability is critical.

Within the chemical processing field, UNS N10276 has an especially favourable reputation for providing reliable service when exposed to high concentrations of hydrochloric acid, sulfuric acid, and other corrosive materials at elevated temperatures. Furthermore, the use of this material helps minimise downtime and reduce maintenance costs through improved corrosion protection when compared to conventional alloys.

Power generation, petroleum refining, and seawater treatment industries are examples of the industries that rely heavily on Hastelloy C276 for applications including heat exchangers, pressure vessels, reactors, and flue gas scrubbers. The amount of molybdenum in Hastelloy C276 is typically between 15% and 17%, which helps to improve the resistance to pitting corrosion in chloride-rich solutions. In addition, the alloy has a total chromium content between 16% and 17%, which improves resistance to oxidation.

Properties of Hastelloy C276

Mechanical Properties and Performance

The mechanical properties of Hastelloy C276 make it a valuable material for many different and difficult applications. Its normal tensile strength is about 690 MPa or 100 ksi and approximately 283 MPa or 41 ksi yield strength provides exceptional ductility and excellent structural integrity together. Hastelloy C276 also retains a high level of elongation capacity that can exceed 40% which allows the material to undergo substantial deformation prior to failure.

In addition, Hastelloy C276 exhibits excellent creep and stress-rupture strengths, which are necessary for applications that experience long-term exposure to elevated temperature and/or pressure. The maximum service temperature of Hastelloy C276 without loss of structural integrity is 1038°C (1900°F). Thermal stability and reliability are paramount in the aerospace, chemical processing and power generation industries.

Corrosion Resistance and Durability

Hastelloy C276 has a reputation for being highly resistant to corrosion and possessing significant durability; therefore, it is extremely well suited for the most demanding service conditions. This alloy made from Nickel, Molybdenum, and Chromium provides excellent resistance to a large number of corrosive environments, both oxidizing and reducing. The low carbon content of Hastelloy C276 reduces the tendency for carbide precipitation to occur during welding, therefore maintaining its resistance to intergranular corrosion (IGC), even in extremely harsh chemical process environments.

Pitting, crevice corrosion, and stress corrosion cracking are some of the key areas where Hastelloy C276 excels. The alloy is very strong against nitric acid and cupric chloride and highly resistant to hot, contaminated mineral acid, wet chlorine gas, and acetic acid. The published results show good performance in applications operating at temperatures of about 1500°F (815°C) preserving their mechanical integrity.

As demonstrated through data from major industry sources, Hastelloy C276 has been shown to withstand HF concentrations of up to 50% at 110°F (43°C). It has also been documented to withstand mixed environments of sulfuric acid and hydrochloric acid equating to outstanding service and reliability under multi-acid conditions.

Common Applications of Hastelloy C276 Round Bar

Industries Utilizing Hastelloy C276

1. Chemical Processing

The most significant global users of Hastelloy C276 are the chemical processing industries. Due to its unique resistance to various types of oxidizers, aggressive acids, and chlorinated solvents, Hastelloy C276 is widely utilized to create many equipment used in chemical manufacturing, such as heat exchangers, reaction vessels and piping systems for transporting liquids or gas. The alloy can withstand the extreme corrosive environments typically found during the chemical manufacture of compounds like hydrochloric acid, sulfuric acid and phosphoric acid.

2. Marine/Ocean Applications

Hastelloy C276 is extensively used in the marine/offshore engineering industry because of its high resistance to seawater-induced crevice corrosion and pitting. In applications such as seawater heat exchangers, parts for shipbuilding, and subsea structures, Hastelloy C276’s durability makes it possible to use them effectively in saline and brackish water conditions. Since the global offshore industries are projected to be worth approximately $180 billion (USD) in 2026, there is an ongoing high demand for durable materials such as Hastelloy C276.

3. Environmental Protection/Pollution Control

There are many other applications of Hastelloy C276 in environmental control. Applications that utilize Hastelloy C276 include flue gas desulphurization systems, duct systems, and damper systems. Due to the intense levels of humidity, acidity and high temperatures that these systems face on a daily basis, the unique characteristics of Hastelloy C276 allow it to remain operationally viable longer than traditional materials. The demand for corrosion-resistant materials for environmental engineering has been steadily increasing in recent years due to increased regulation and the increasing desire for sustainable engineering solutions.

4. Power Generation

Hastelloy C276 is commonly used in a variety of different systems found in power plants that utilize fossil fuels. Many of these systems use Hastelloy C276 in applications that are exposed to very high levels of corrosive chemicals, such as flue gas desulphurization (FGD) and heat exchanger applications. Because of its unique ability to withstand both high temperatures and very aggressive chemical environments, Hastelloy C276 is a must-have material for making sure that companies maintain the integrity of their operations in the power generation sector.

Specific Applications for C276 Bars

- Chemical Processing Industry – The applications of C276 bars in the chemical processing industry include heat exchangers, chemical reactors, and storage tanks; therefore, whenever designing any component of a chemical processing facility, C276 bars should be specified due to their high strength and durability, allowing them to be suitable for use in the highest performance applications that require a high-performance material.

- Desalination Plants – In the desalination industry, the significant corrosion resistance properties of C276 bars make them perfect for seawater desalination systems, as seawater is highly corrosive. Pumps, piping systems, and pressure vessels in seawater reverse osmosis processes use C276 bars in order to create a safe and extended life cycle for these components.

- Aerospace Parts – C276 Bars are critical components used in aerospace applications (jet engines and exhaust systems) in which there will continue to be increased amounts of demand for the material. They are typically used in the aerospace industry due to their stable thermal performance under extreme temperatures, as well as the ability of C276 bars to resist oxidation and perform under high-stress conditions, thereby ensuring optimal aircraft performance under all operating conditions.

- The Pharmaceutical and Food Processing Industry – The Pharmaceutical and Food Processing Industry operates under strict sanitary standards; therefore, special materials are needed for hygienic processing equipment. Using C276 bars will significantly reduce the risk of contamination of the products that are processed using these types of equipment.

Benefits of Choosing Chinese Manufacturers

Cost-Effectiveness and Competitive Pricing

Due to their ability to manufacture quality products such as Hastelloy C276 bars for lower prices than most competing manufacturers in the world today, Chinese manufacturers have become well known in the global market. By taking advantage of their innovative manufacturing technologies and large scale manufacturing processes, many Chinese suppliers are able to cut production costs without sacrificing the quality of the metal used to produce, and thus provide the best possible value to their customers.

Research conducted recently shows that the price of Hastelloy C276 bars that originate from China will typically be 20-30% lower than similar products offered for sale by western manufacturers. Therefore, for many businesses that are trying to maximize their budget, Chinese manufacturers are a good option.

Another reason why Chinese manufacturers are able to supply the best value for customers is due to their more efficient and streamlined supply chain, as well as their extensive and reliable export systems. As such, Chinese companies offer quicker production times, as well as the assurance of receiving products on their anticipated delivery dates, with significantly lower shipping costs. Understandably, many suppliers based in China have flexible options for customizing their products for customers, allowing companies to acquire exactly what they need, while providing them with the added benefit of not having to pay additional expense for this service.

Quality Guidelines and Certifications Among Chinese Manufacturers of Hastelloy C276 Bars

Chinese suppliers of Hastelloy C276 bars follow strict quality standards and certifications to ensure their products meet international specifications. The vast majority of these suppliers adhere to certifications specific to Quality Management Systems as recognized by www.iso.org, as well as ASTM (American Society for Testing and Materials) guidelines, which establish mechanical and chemical standards for corrosion-resistant, high-pressure materials.

Further, many manufacturers also have specific certifications that pertain to the manufacture of products intended for use in extreme pressure and / or corrosion-resistant environments, including PED (Pressure Equipment Directive) and NACE (National Association of Corrosion Engineers). According to recent industry surveys, approximately 85% of the suppliers of metal alloys in China are certified for use in international markets. Additionally, the trend toward the increased use of advanced technologies, including non-destructive testing (NDT) methods, will continue to provide manufacturers in China with a mechanism to monitor the integrity of their products prior to shipment.

Quality Standards and Certifications

ASTM B574 Compliance

Material Composition and Properties

The ASTM B574 specification includes a number of key component materials including very high nickel content, approximately 58% nickel as well as very high molybdenum and chromium concentrations, approximately 16% molybdenum and approximately 15% chromium. These specific components have proven excellent performance in acid-rich environments including HCl and H2SO4. Products manufactured to this standard are highly resistant to both pitting and crevice corrosion, even under very difficult conditions.

Applications of ASTM B574 Compliant Products

Products manufactured under ASTM B574 are frequently used in the manufacturing of heat exchangers, pressure vessels, and piping systems in environments with high temperature and caustic/chemical conditions. For example, oil and gas pipelines manufactured using ASTM B574 compliance materials can withstand the effects of corrosive materials and extreme loads, ensuring long-term reliability and low maintenance costs.

Testing and Certification

To be certified as complying with ASTM B574, materials must go through a rigorous testing process including tensile testing, impact testing, and non-destructive testing (NDT) methods to determine the integrity of materials. Once the integrity of the materials has been established, manufacturers supply mill test reports (MTR) to demonstrate compliance with ASTM B574, which includes the results of chemical composition testing and the mechanical property testing required by ASTM B574.

Importance of Quality Assurance for Chemical Applications

Quality assurance (QA) is a critical component of the chemical industry due to the importance of precision and safety, as well as performance. The integrity of chemical products is dependent upon strict QA procedures to ensure compliance with national and international industry standards and regulations. The QA frameworks provided by organizations like the International Organization for Standardization (ISO) and ASTM International provide standardization across the chemical manufacturing industry to minimize risk from defective or non-compliant materials.

According to the most recent available statistics, about 70% of failures related to chemicals caused by poor quality of material or incorrect production processes. The implementation of QA frameworks enable quality related issues including variation of chemical composition and inconsistencies of mechanical properties to be detected and corrected early. Commonly available techniques used for QA include spectroscopic analysis, chromatography, and tensile testing to verify material properties against specified criteria.

Reference Sources

-

Selection of Inhibited Preservative Materials for Corrosion Protection

- Key Findings: This study examined corrosion protection methods for alloys, including Hastelloy C-276. It highlighted the effectiveness of coatings in reducing corrosion rates while maintaining low toxicity.

- Methodology: The research involved testing various coatings on alloys like Hastelloy C-276 and Monel 400, measuring corrosion rates under different conditions.

- Read the study

-

Microstructural Analysis of Spin Arc Welding on Hastelloy C-276

- Key Findings: This research focused on the effects of spin arc welding on Hastelloy C-276. It found significant improvements in hardness, microstructure, and structural integrity when using a 1.2 mm diameter filler rod.

- Methodology: The study analyzed welded joints of Hastelloy C-276, using microstructural and hardness tests to evaluate the results.

- Read the study

-

Experimental Investigation into Machining of Hastelloy C-276

- Key Findings: This study explored machining processes for Hastelloy C-276 under various cooling environments. It provided insights into chip formation and machining quality for cylindrical bars of 56 mm diameter and 550 mm length.

- Methodology: The research involved experimental machining tests, analyzing chip formation, surface finish, and tool wear under different cooling conditions.

- Read the study

Frequently Asked Questions (FAQs)

What is Alloy C-276, and why is Hastelloy C-276 used in the production of Nickel Alloys?

Alloy C-276 (Hastelloy C-276) is a Nickel-Molybdenum-Chromium Alloy with additives of Tungsten that offers superior corrosion resistance and high performance in challenging conditions. As a nickel alloy rod/bar, Hastelloy C-276 is extremely resistant to pitting, crevice and stress-corrosion cracking. This makes it an appropriate material for chemical processing, chlorine dioxide service, and other applications that require corrosion-resistant materials in major industries.

What type of forms are available for Hastelloy C276 Bars and Round Bars from Chinese manufacturers and suppliers?

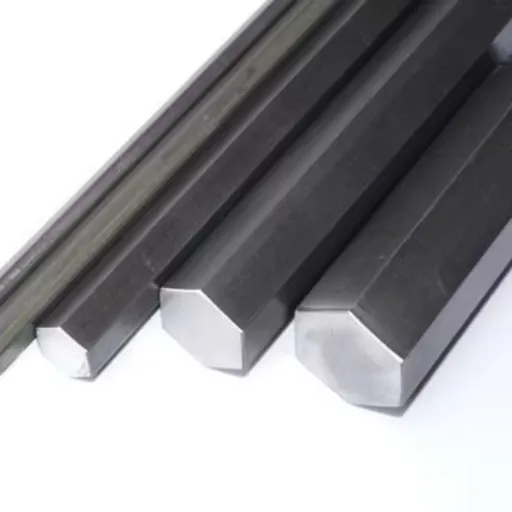

Hastelloy C276 products from Chinese Manufacturers and Suppliers can be found as Round Bars, Flat Bars, Hexagon/Shaped Bars, Rods and custom made shapes. The most common types include: Alloy C276 Round Bar, Alloy C276 Flat Bar, Nickel Alloy Round Bar and Hastelloy C276 rods. Many manufacturers and suppliers also offer Solution Annealed, Heat Treated and High Strength products to meet industrial application needs.

How do I select a qualified exporter or supplier of Hastelloy Alloy C276 and associated products?

To ensure you have selected a qualified exporter or supplier, you should evaluate their Certification, Material Test Reports (MTR) for compliance with Standards such as ASTM B574 Hastelloy, References from Other Customers, and Ability to Customise your order requirements. Most Leading Suppliers tend to include their Experience in producing C-276 Nickel Alloys, Nickel Alloy Bars and related products, Quality Control Processes, Supply Chain Transparency and After-Sales Support as part of their company profiles.

What is the standard Chemical Composition and Property Range of Alloy C-276 round bar (2.4819)?

Typically, Alloy C-276 (UNS N10276, EN No. 2.4819) has high Nickel with significant Molybdenum and Chromium with very low levels of Tungsten, Iron and Cobalt. This composition gives Alloy C-276 excellent resistance to both oxidising and reducing media, Chloride Solutions and Strong Acids. Most manufacturers have detailed chemical composition certification and mechanical property data for compliance with specifications and other customers.

Conclusion

Hastelloy C276 round bars from Chinese manufacturers offer an exceptional combination of superior corrosion resistance, mechanical strength, and cost-effectiveness. With stringent quality certifications, competitive pricing, and proven reliability across diverse industrial applications, these products represent an excellent choice for businesses seeking high-performance materials that meet international standards.