Get in touch with us

Leave a message

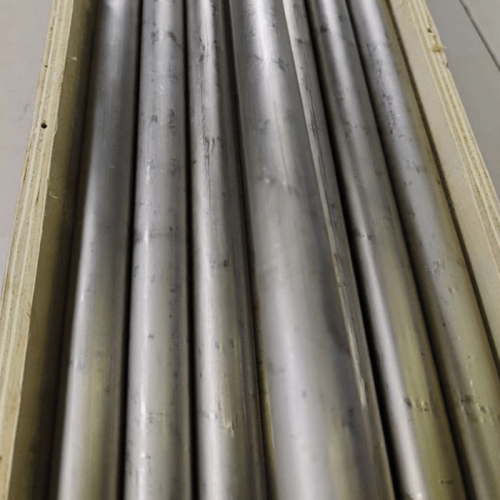

The MP159 Cobalt Alloy Tube is a high-performance cobalt alloy steel designed for extreme environments. Renowned for its exceptional strength, corrosion resistance, and durability, this chromium cobalt nickel alloy is ideal for demanding applications in aerospace, medical, and industrial sectors. As a leading manufacturer in China, we ensure top-tier quality and precision in every tube.

For detailed pricing on MP159 Cobalt Alloy Tube, including bulk order discounts and shipping terms, please contact our sales team through our inquiry form. Pricing varies based on specifications, quantity, and customization requirements.

Outer Diameter: 0.5–6 inches (12.7–152.4 mm)

Wall Thickness: 0.02–0.5 inches (0.5–12.7 mm)

Length: Up to 20 ft (6.1 m) or custom-cut

Surface Treatment: Annealed, polished, or as per request

Tolerances: ±0.005 inches for OD, ±0.002 inches for wall thickness

Standards: ASTM B983, AMS 5754

The MP159 Cobalt Alloy Tube is widely used across industries due to its robust cobalt alloy properties. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | 35.0 - 39.0 |

| Nickel (Ni) | 24.0 - 26.0 |

| Chromium (Cr) | 18.0 - 20.0 |

| Iron (Fe) | 8.0 - 10.0 |

| Molybdenum (Mo) | 6.0 - 8.0 |

| Titanium (Ti) | 0.5 - 1.0 |

| Property | Value |

|---|---|

| Tensile Strength | 1100 - 1400 MPa |

| Yield Strength | 900 - 1100 MPa |

| Elongation | 10 - 20% |

| Hardness | 35 - 45 HRC |

The MP159 Cobalt Alloy Tube exhibits excellent resistance to acids (e.g., sulfuric and hydrochloric) and alkalis, making it suitable for chemical processing. It complies with environmental regulations, with no restricted substances under RoHS.

While highly versatile, the MP159 Cobalt Alloy Tube has limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | 0.02 - 0.05 |

| Mild Acidic Solutions | 0.01 - 0.03 |

The MP159 Cobalt Alloy Tube supports multiple welding methods, including TIG, MIG, and plasma welding. Cold working and annealing enhance formability. Machining requires high-speed tools due to its hardness.

The MP159 tubes we sourced from this China manufacturer exceeded our expectations for strength and finish. Perfect for our turbine components.

John D.

Aerospace Engineer

These cobalt alloy tubes are biocompatible and easy to fabricate, saving us time in production.

Emily R.

Medical Device Designer

Reliable performance in corrosive environments. The cobalt alloy price is justified by its durability.

Michael T.

Oil & Gas Manager

A: While both are cobalt-based, MP159 Cobalt Alloy Tube offers higher tensile strength than Stellite, but Stellite excels in wear resistance.

A: Aerospace, medical, oil & gas, and chemical processing industries.

A: Yes, up to 600°C, but prolonged exposure may affect performance.

A: MP159 offers higher tensile strength and better fatigue resistance than Stellite, making it ideal for aerospace, while Stellite is often used for wear-resistant coatings.

A: Aerospace, oil and gas, medical, and marine industries rely on MP159 Cobalt Alloy Tube for its strength and corrosion resistance.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.