Get in touch with us

Leave a message

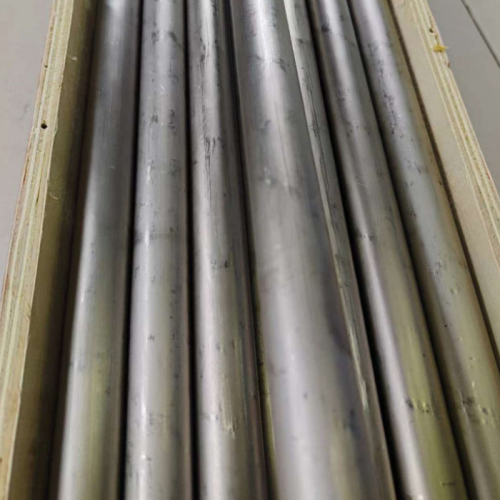

The Stellite100 Cobalt Alloy Pipe is a high-performance product designed for extreme environments. Known for its exceptional cobalt alloy properties, this pipe offers superior wear resistance, corrosion resistance, and high-temperature stability. Manufactured by our trusted China factory, it serves industries requiring durable chromium cobalt nickel alloy solutions, such as aerospace, power generation, and chemical processing.

For competitive pricing on Stellite100 Cobalt Alloy Pipe, contact our sales team for a personalized quote. Pricing terms are flexible, tailored to order volume and specifications. Reach out to discuss your needs with our China-based enterprise.

The Stellite100 Cobalt Alloy Pipe excels in demanding applications, including:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | 50-55% |

| Chromium (Cr) | 28-32% |

| Nickel (Ni) | 10-12% |

| Tungsten (W) | 4-6% |

| Carbon (C) | 1-2% |

| Others (Fe, Si, Mn) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | 850-1000 MPa |

| Yield Strength | 600-750 MPa |

| Elongation | 10-15% |

| Hardness (HRC) | 40-50 |

The Stellite100 Cobalt Alloy Pipe offers excellent resistance to acids (e.g., sulfuric and hydrochloric) and alkalis, making it ideal for chemical processing. However, prolonged exposure to highly concentrated oxidizing acids may require additional coatings. This product complies with environmental regulations, but recycling is recommended due to cobalt content.

While the Stellite100 Cobalt Alloy Pipe is highly durable, note the following:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | <0.02 |

| 10% Sulfuric Acid | 0.05-0.1 |

| 10% Hydrochloric Acid | 0.1-0.2 |

Recommended welding methods for Stellite100 Cobalt Alloy Pipe include:

Fabrication involves cold forming for thinner pipes and hot forming for thicker ones. Machining requires carbide tools due to the alloy’s hardness. Annealing may be needed post-fabrication to relieve stresses.

The Stellite100 Cobalt Alloy Pipe from this China manufacturer exceeded our expectations for turbine applications. Its durability in high-heat environments is unmatched.

John D.

Aerospace Engineer

We’ve used these pipes for our acidic processing lines, and their corrosion resistance is exceptional. Great value for the cobalt alloy price.

Emma L.

Chemical Plant Manager

Reliable and easy to weld. The Stellite pipes have significantly reduced our maintenance downtime.

Michael T.

Oil & Gas Supervisor

A: Stellite100 has a higher cobalt and chromium content, enhancing its wear and corrosion resistance compared to other chromium cobalt nickel alloy variants.

A: It’s widely used in aerospace, chemical processing, and oil and gas due to its robust cobalt alloy properties.

A: Yes, up to 1000°C, but prolonged exposure to oxidizing environments may require additional protection.

A: TIG and plasma arc welding are recommended for optimal results.

A: Yes, but recycling is advised due to cobalt content.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.