Get in touch with us

Leave a message

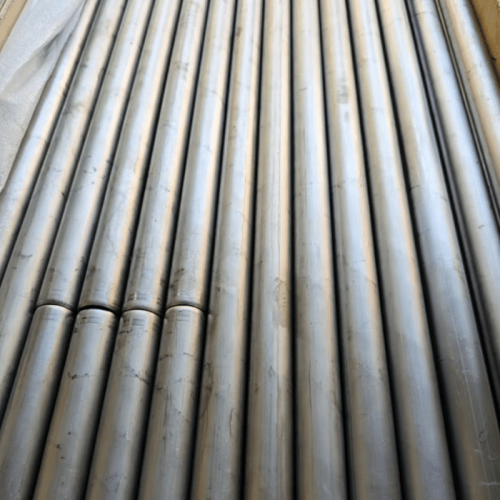

Stellite 12 Cobalt Alloy Pipe, crafted by our trusted China manufacturer, is a high-performance chromium cobalt nickel alloy engineered for durability and resilience. Known for its excellent wear and corrosion resistance, this cobalt alloy steel excels in harsh environments, making it a preferred choice for aerospace, oil & gas, and industrial applications. Its robust cobalt alloy composition ensures long-lasting performance under demanding conditions.

Contact our sales team for a tailored quote on Stellite 12 Cobalt Alloy Pipe. Pricing varies based on specifications, order size, and delivery terms. Reach out to our China-based factory to discuss cobalt alloy price options suited to your project requirements.

Stellite 12 Cobalt Alloy Pipe is valued for its cobalt alloy properties across various industries. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance (approx. 55-60%) |

| Chromium (Cr) | 28-32% |

| Tungsten (W) | 7-9% |

| Nickel (Ni) | 0-2.5% |

| Carbon (C) | 1.4-2.0% |

| Others (Fe, Si, Mn) | ≤3% |

| Property | Value |

|---|---|

| Tensile Strength | 950-1150 MPa |

| Yield Strength | 650-850 MPa |

| Elongation | 8-15% |

| Hardness (HRC) | 40-48 |

The cobalt alloy properties of Stellite 12 Cobalt Alloy Pipe include excellent resistance to acids like sulfuric and hydrochloric, as well as alkalis, making it suitable for corrosive environments. However, it may require protective coatings in highly oxidizing conditions, such as concentrated nitric acid. This alloy complies with environmental standards, but recycling is recommended to minimize cobalt-related environmental impact.

While Stellite 12 Cobalt Alloy Pipe is highly versatile, consider these limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Marine) | <0.01 |

| Mild Chemical (pH 4-10) | <0.04 |

| Sulfuric Acid (10%) | 0.15-0.35 |

| Hydrochloric Acid (5%) | 0.25-0.6 |

Stellite 12 Cobalt Alloy Pipe supports welding methods like TIG (Tungsten Inert Gas) and plasma arc welding, using Stellite-compatible fillers to preserve cobalt alloy properties. Fabrication techniques include:

The Stellite 12 Cobalt Alloy Pipe from this China factory is outstanding. It handles corrosive fluids perfectly, and the quality is top-notch. Highly recommend!

Emma R.

Oil & Gas Engineer

These pipes are a game-changer for our engine components. The cobalt alloy composition ensures durability, and the manufacturer’s service was excellent.

David K.

Aerospace Technician

We rely on Stellite 12 Cobalt Alloy Pipe for our processing plants. Its corrosion resistance is unmatched, and the China distributor delivered on time.

Lisa P.

Chemical Engineer

A: Stellite 12 offers superior wear and corrosion resistance due to its cobalt alloy composition, ideal for extreme conditions unlike standard stainless steel.

A: It’s used in aerospace, oil & gas, chemical processing, and power generation for components like pipes, valves, and turbines.

A: Yes, TIG and plasma arc welding are recommended for optimal results.

A: It meets environmental standards, but recycling is advised to reduce cobalt impact.

A: Its high wear resistance, corrosion resistance, and stability in harsh environments make it unique.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.