Get in touch with us

Leave a message

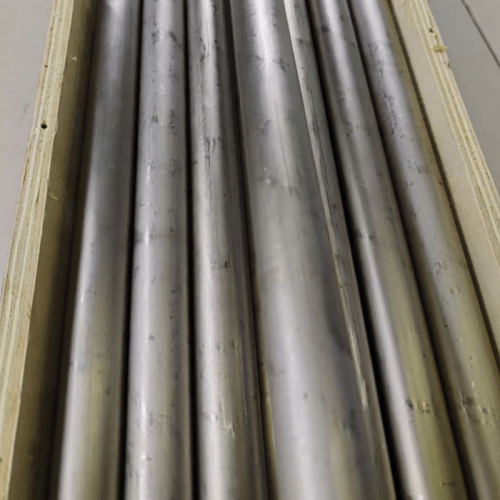

Stellite 20 Cobalt Alloy Tube, produced by our reputable China manufacturer, is a high-performance chromium cobalt nickel alloy designed for exceptional durability. Renowned for its superior wear and corrosion resistance, this cobalt alloy steel thrives in extreme conditions, making it ideal for aerospace, chemical, and industrial applications. Its robust cobalt alloy composition ensures reliability in demanding environments.

Contact our sales team for a customized quote on Stellite 20 Cobalt Alloy Tube. Pricing depends on specifications, order volume, and delivery terms. Reach out to our China-based factory to explore cobalt alloy price options tailored to your needs.

Stellite 20 Cobalt Alloy Tube is valued for its cobalt alloy properties in demanding industries. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance (approx. 50-55%) |

| Chromium (Cr) | 30-34% |

| Tungsten (W) | 13-16% |

| Nickel (Ni) | 0-2% |

| Carbon (C) | 2.0-2.5% |

| Others (Fe, Si, Mn) | ≤3% |

| Property | Value |

|---|---|

| Tensile Strength | 1000-1200 MPa |

| Yield Strength | 700-900 MPa |

| Elongation | 5-10% |

| Hardness (HRC) | 45-52 |

The cobalt alloy properties of Stellite 20 Cobalt Alloy Tube include excellent resistance to acids (e.g., sulfuric, hydrochloric) and alkalis, making it ideal for corrosive environments. However, it may require coatings in highly oxidizing acids like nitric acid. This alloy complies with environmental regulations, but recycling is recommended to minimize cobalt-related environmental impact.

While Stellite 20 Cobalt Alloy Tube is highly durable, consider these limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Marine) | <0.01 |

| Mild Chemical (pH 4-10) | <0.03 |

| Sulfuric Acid (10%) | 0.1-0.4 |

| Hydrochloric Acid (5%) | 0.3-0.7 |

Stellite 20 Cobalt Alloy Tube supports welding methods like TIG (Tungsten Inert Gas) and plasma arc welding, using Stellite-compatible fillers to maintain cobalt alloy properties. Fabrication techniques include:

The Stellite 20 Cobalt Alloy Tube from this China factory is exceptional. Perfect for our turbine components, with outstanding durability and timely delivery.

Mark S.

Aerospace Engineer

These tubes handle corrosive chemicals flawlessly. The cobalt alloy composition is top-quality, and the manufacturer’s service is reliable.

Anna T.

Chemical Plant Supervisor

Stellite 20 Cobalt Alloy Tube is a game-changer for our machinery. Its wear resistance is unmatched, and the China distributor provided excellent support.

James R.

Industrial Manager

A: Stellite 20 offers superior wear and corrosion resistance due to its cobalt alloy composition, outperforming stainless steel in extreme conditions.

A: It’s used in aerospace, chemical processing, oil & gas, and industrial applications for components like turbines, piping, and valves.

A: Stellite 20 is costlier than stainless steel but offers unmatched durability. Contact us for a quote.

A: It meets environmental standards, but recycling is advised to reduce cobalt impact.

A: Its exceptional wear resistance, corrosion resistance, and high-temperature stability set it apart.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.