Get in touch with us

Leave a message

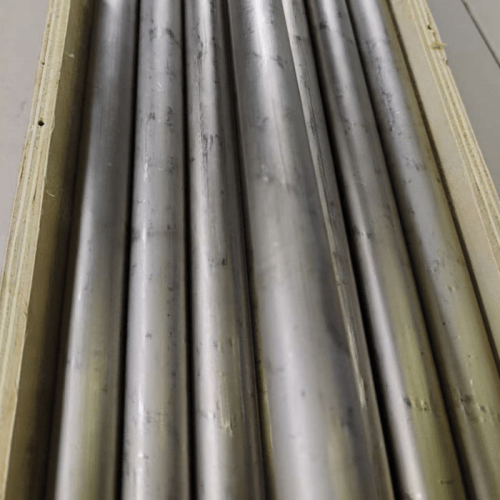

Stellite3 Cobalt Alloy Pipe, a high-performance chromium cobalt nickel alloy, is designed for exceptional wear and corrosion resistance. Produced by our China manufacturer, this cobalt alloy steel excels in extreme conditions, making it a top choice for industries requiring durable piping solutions. Its cobalt alloy composition delivers superior strength and longevity.

For a customized quote on Stellite3 Cobalt Alloy Pipe, contact our sales team. Pricing is based on specifications, order quantity, and delivery terms. Our China enterprise ensures competitive rates for your needs.

Stellite3 Cobalt Alloy Pipe is utilized across various cobalt alloy uses in industries such as:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 29-33 |

| Tungsten (W) | 12月14日 |

| Carbon (C) | 2.3-2.8 |

| Nickel (Ni) | ≤2.5 |

| Iron (Fe) | ≤2.0 |

| Property | Value |

|---|---|

| Tensile Strength | 900-1050 MPa |

| Yield Strength | 650-800 MPa |

| Elongation | 8-12% |

| Hardness | HRC 52-60 |

Stellite3 Cobalt Alloy Pipe offers robust resistance to acids (e.g., hydrochloric and phosphoric) and alkalis, ideal for harsh chemical settings. It adheres to environmental standards, with no restricted substances in its cobalt alloy composition. However, exposure to highly concentrated oxidizing agents may necessitate protective measures.

Despite its strengths, Stellite3 Cobalt Alloy Pipe has some limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Industrial) | <0.01 |

| Seawater | 0.03-0.06 |

| 10% Hydrochloric Acid | 0.15-0.4 |

| 5% Phosphoric Acid | <0.08 |

Stellite3 Cobalt Alloy Pipe supports multiple welding methods, including:

Fabrication involves hot forming at 1050-1200°C, followed by annealing to reduce stresses. Machining requires diamond or carbide tools due to the alloy’s hardness.

The Stellite3 Cobalt Alloy Pipe from this China manufacturer has been a game-changer for our corrosive fluid systems. Exceptional quality!

Emily R.

Petrochemical Engineer

These pipes handle high temperatures and wear like no other. The cobalt alloy properties are top-notch.

David K.

Power Plant Technician

Stellite3 pipes have significantly reduced maintenance costs in our slurry lines. Highly recommend this distributor.

Lisa M.

Mining Operations Manager

A: Stellite3 has a higher carbon content than Stellite 6, offering greater wear resistance but lower toughness.

A: It’s ideal for petrochemical, aerospace, marine, and power generation applications.

A: Stellite3 has a higher carbon content, enhancing wear resistance but reducing ductility compared to alloys like Stellite6.

A: Aerospace, chemical processing, and oil & gas industries leverage its corrosion and heat resistance.

A: TIG and plasma arc welding provide the best results for integrity and finish.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.